A six-degree-of-freedom tactile sensor and its decoupling design method

A tactile sensor, degree of freedom technology, applied in the field of sensors, can solve the problem of inability to meet the urgent needs of simultaneous acquisition, achieve ultra-high sensitivity measurement, improve decoupling efficiency, and eliminate common mode signals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

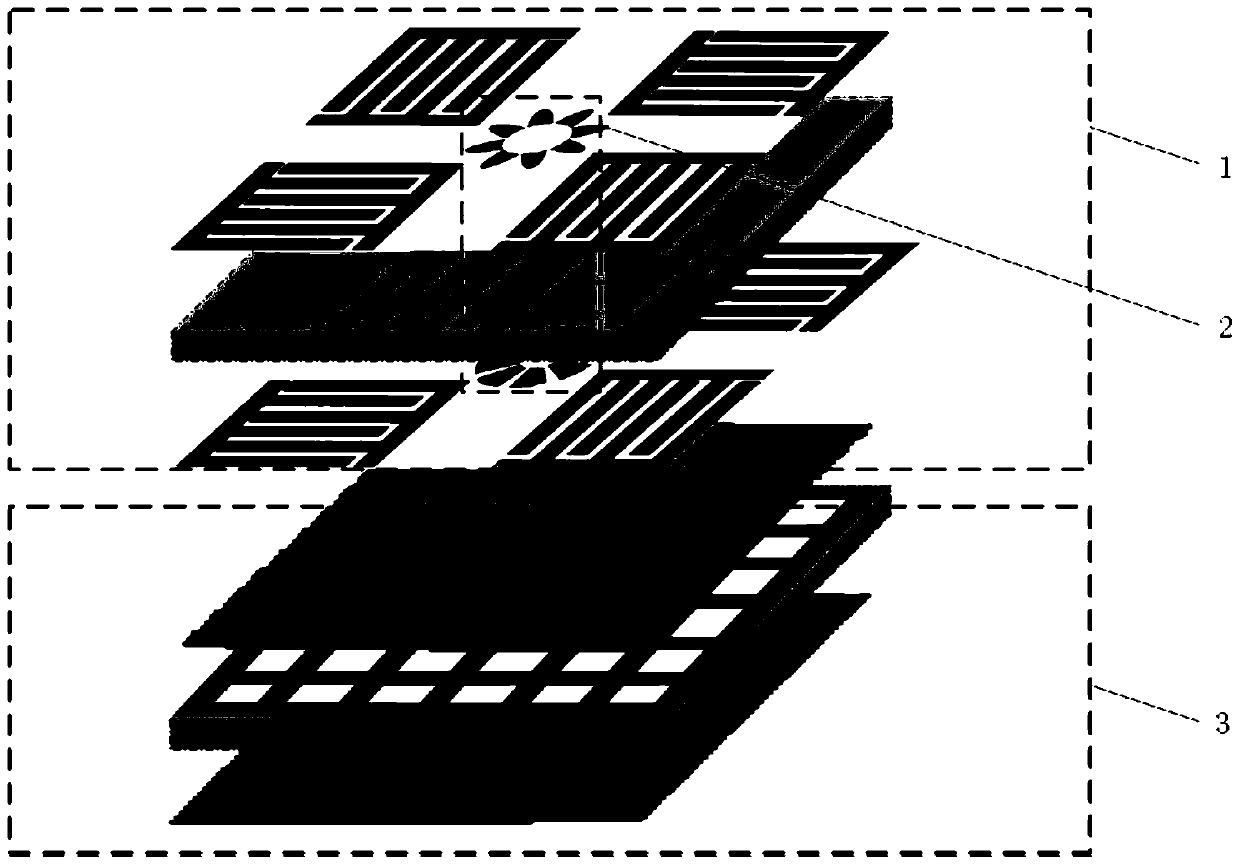

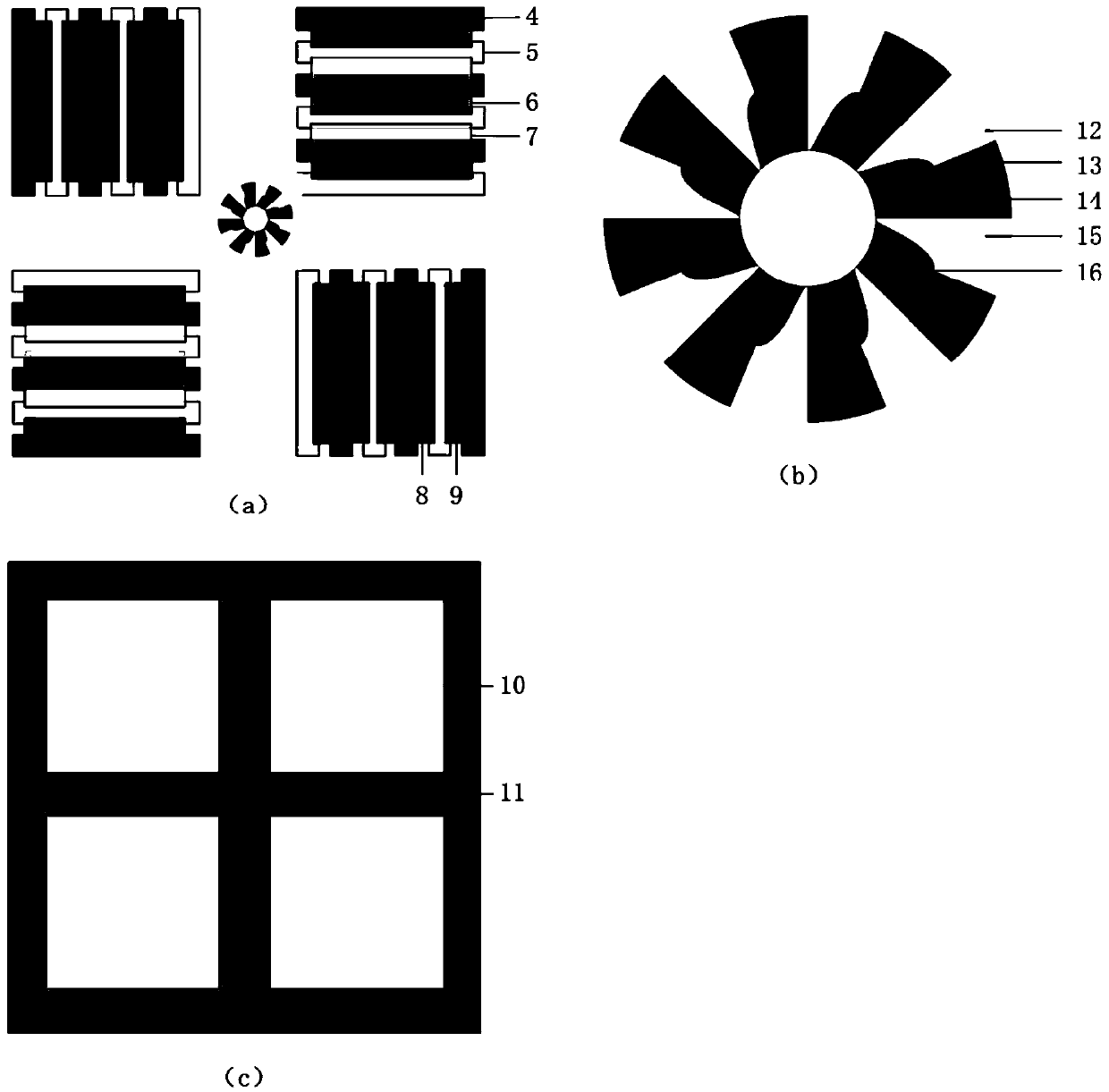

[0030] Such as figure 1 As shown, this implementation example is based on a six-degree-of-freedom tactile sensor, which is mainly composed of a shear sensing unit 1, a torsion sensing unit 2, and a positive pressure array sensing unit 3. The sensing mechanisms of the three sensing units are all based on capacitive conduction. Due to the external force acting on the sensor, the capacitance structure parameters of the sensor will change. By measuring the capacitance change, the positive pressure Fz, shear force Fx / Fy, and torque Mz / Mx / My acting on the sensor can be sensed. The working principle is as follows image 3 shown.

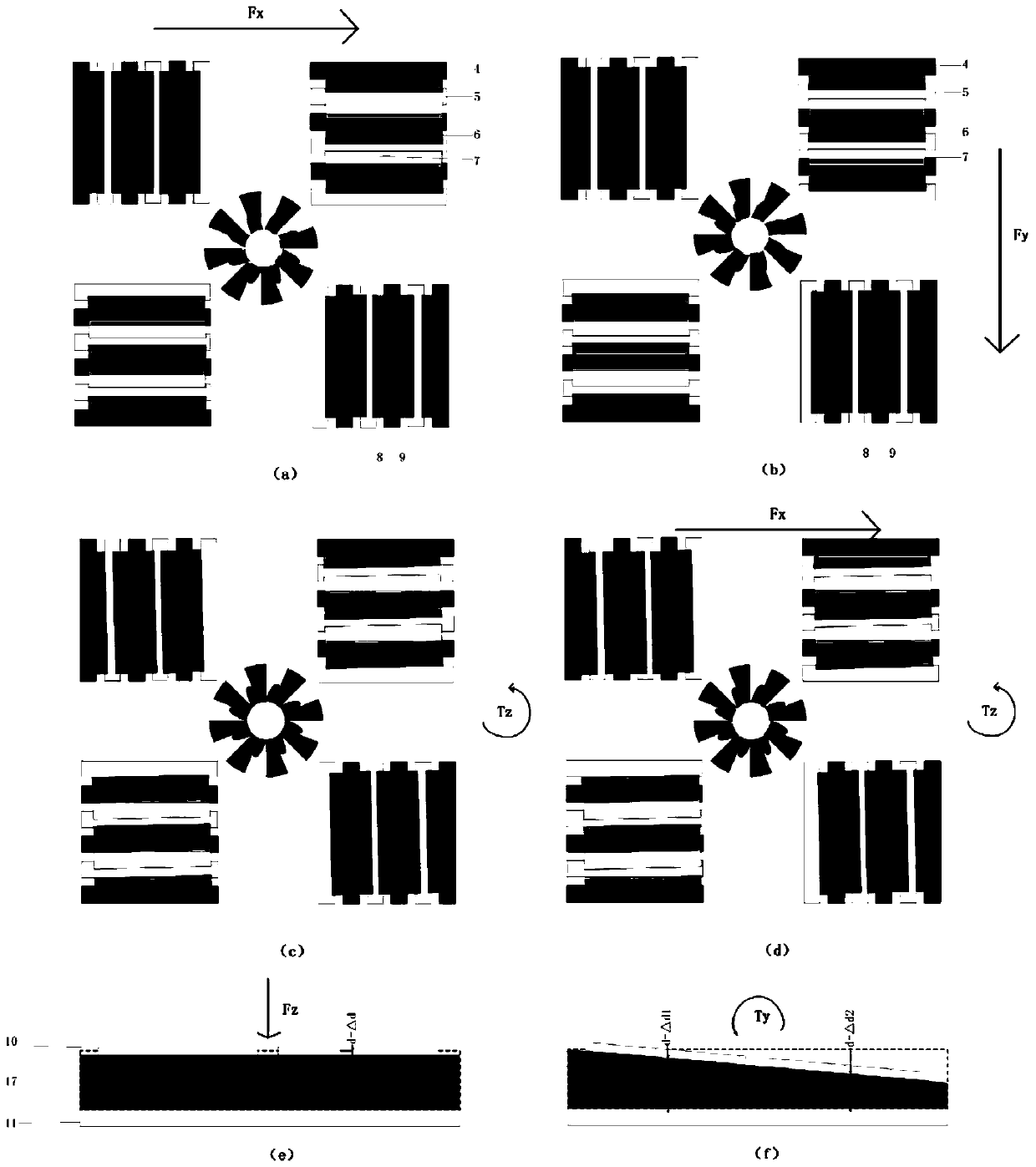

[0031] The tactile sensor is under the action of the shear force Fx (such as image 3 As shown in (a)), the X-direction finger-shaped sensing pole 8 / 9 moves in opposite directions relative to the X-direction grounding pole, which reduces / increases the facing area of the plate, thus forming a pair of sensing X The differential electrode for the shearing ...

example 2

[0036]The decoupling design method and specific working steps of the six-degree-of-freedom tactile sensor are illustrated with an example. In this example, the six-degree-of-freedom tactile sensor is subjected to an external force, and the force it receives is a combination of forces from three different directions and a torque Synthesis, that is, the force (Fx / Fy / Fz) in the X / Y / Z direction and the torque in the Z direction (Tz). The resultant force causes the sensing poles of the three sensing units of the tactile sensor to rotate in the Z direction, move in the X / Y direction, and compress / stretch in the Z direction relative to their grounding poles. After decoupling the structure of each unit of the sensor, Each unit can eliminate the influence of other force / moment, decoupling design such as figure 2 shown.

[0037] where the positive pressure sensing unit 3, such as figure 2 As shown in (c), the z-direction grounding electrode 11 is slightly larger than the peripheral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com