Direct type backlight module and display terminal

A backlight module, direct type technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as the inability to achieve thinning of the TV and the overall thickness of the backlight module.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

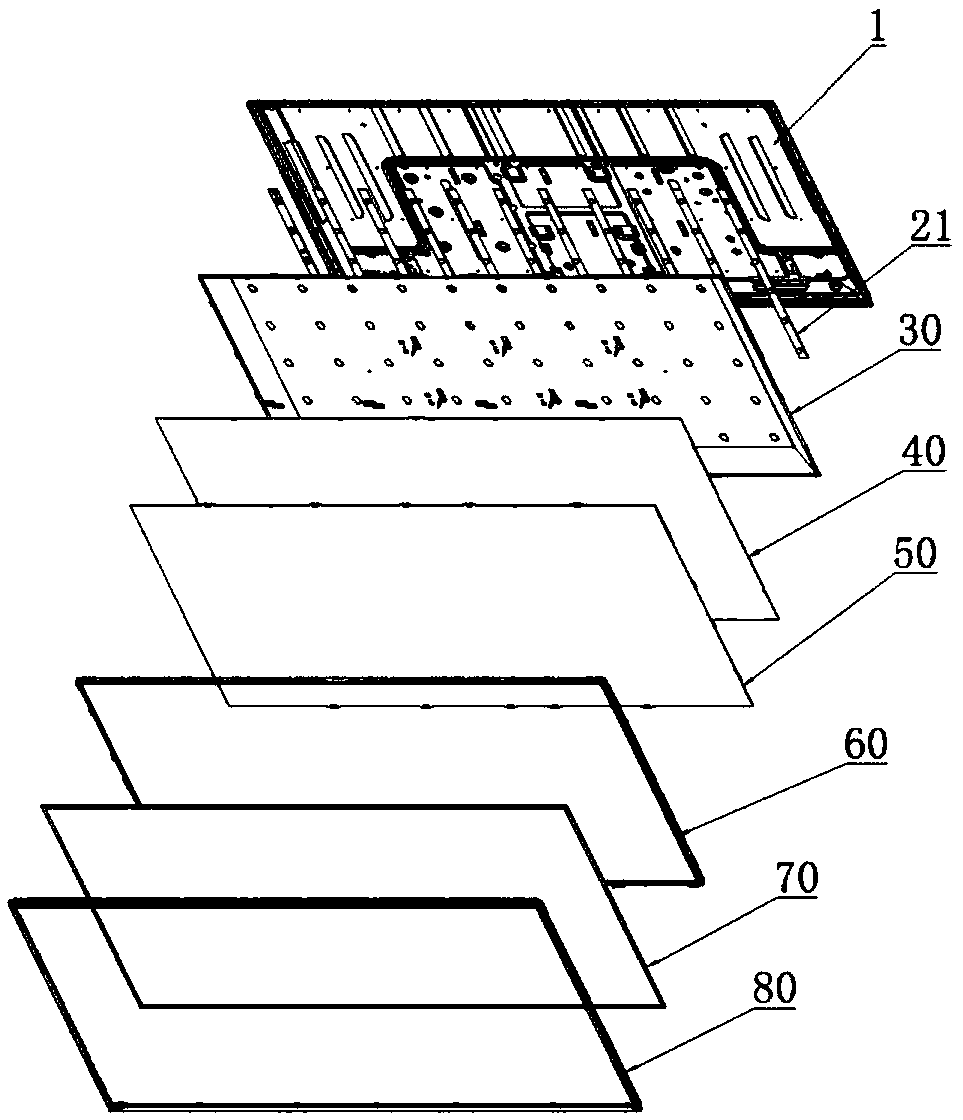

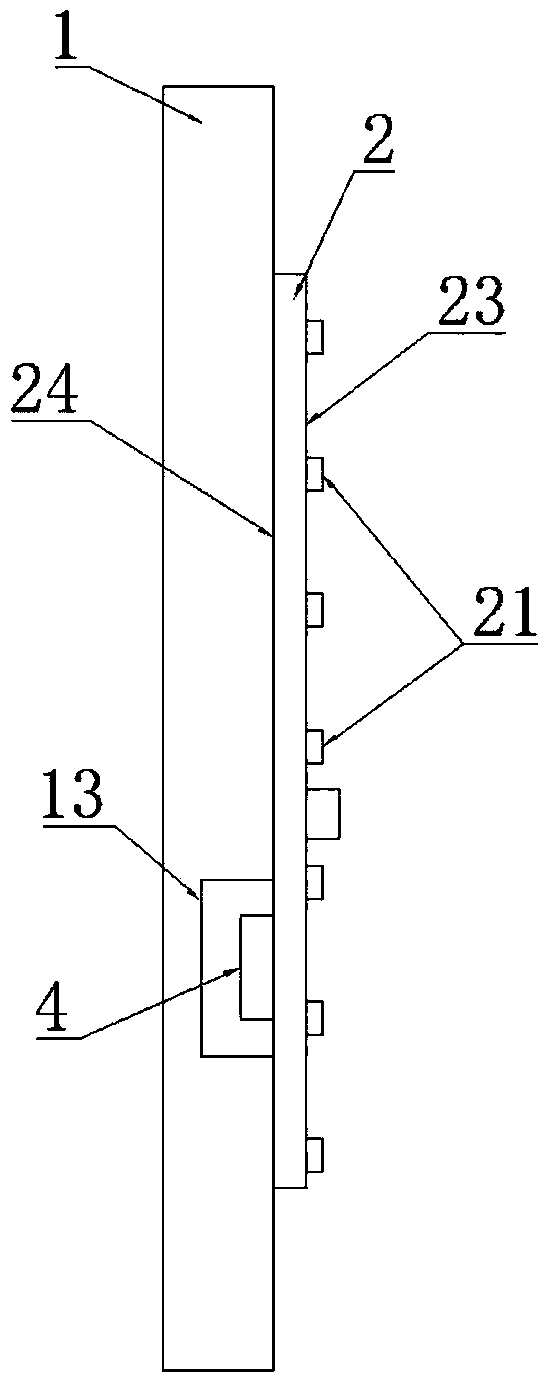

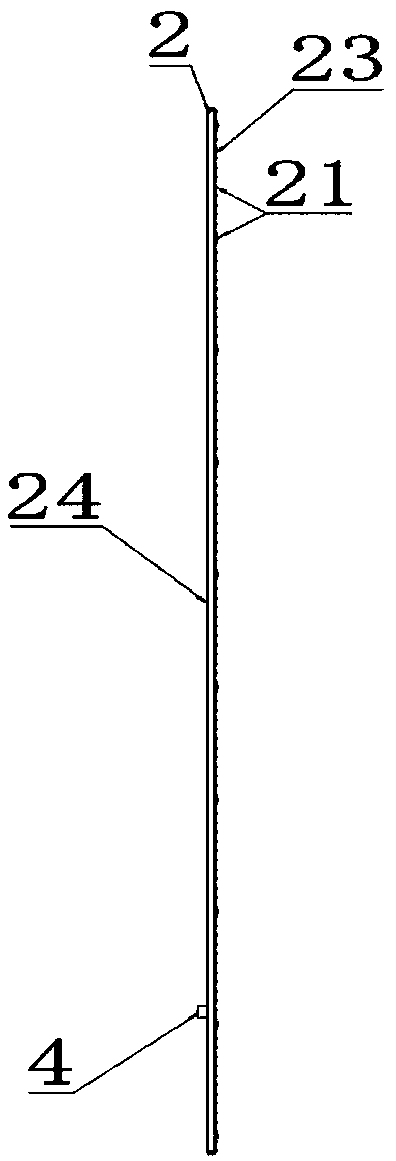

[0035] Such as figure 2 As shown, the direct-lit backlight module provided by the embodiment of the present application includes a lamp panel 2, and the first surface 23 of the lamp panel 2 is provided with LED lamps 21 arranged in an array, as shown in image 3 , Figure 4 As shown; the second surface 24 of the lamp board 2 is provided with the wiring terminal 4 of the LED lamp 21, as Figure 5As shown, the LED lamp 21 is electrically connected to the wiring terminal 4, and the wiring terminal 4 is used for external electrical connection, wherein the first surface 23 and the second surface 24 of the lamp board 2 are two opposite surfaces of the lamp board 2 .

[0036] In the direct type backlight module, the wiring terminals 4 are arranged on the second surface 24 of the lamp board 2 , so that the integration of the LED lamp 21 and the wiring terminals 4 is realized. Specifically, the wire terminal 4 integrated with the LED lamp 21 is electrically connected to the LED lam...

Embodiment 2

[0048] The direct-lit backlight module provided in the embodiment of the present application includes a lamp panel 2, and the first surface 23 of the lamp panel 2 is provided with LED lamps 21 arranged in an array, such as Figure 9 As shown; the second surface 24 of the lamp board 2 is provided with the wiring terminal 4 of the LED lamp and the lamp board driving module 22, as Figure 10 As shown; the LED lamp 21 is electrically connected to the wiring terminal 4 and the lamp board driving module 22, and the wiring terminal 4 is used for external electrical connection, wherein the first surface 23 and the second surface 24 are the opposite two sides surface.

[0049] In the direct type backlight module, the wiring terminal 4 and the lamp board driving module 22 are simultaneously arranged on the second surface 24 of the lamp board 2 , realizing the integration of the LED lamp 21 , the wiring terminal 4 and the lamp board driving module 22 . Specifically, the wiring terminal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com