Method for improving deformation uniformity of core wires of NbTi/Cu superconducting wire

A superconducting wire, uniformity technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of uneven deformation of the core wire of wire rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

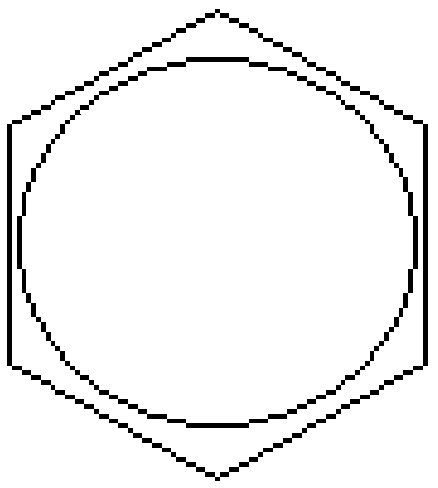

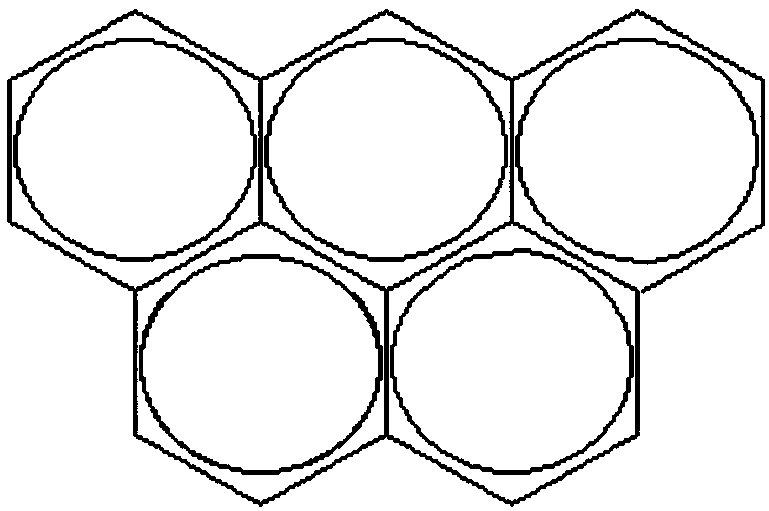

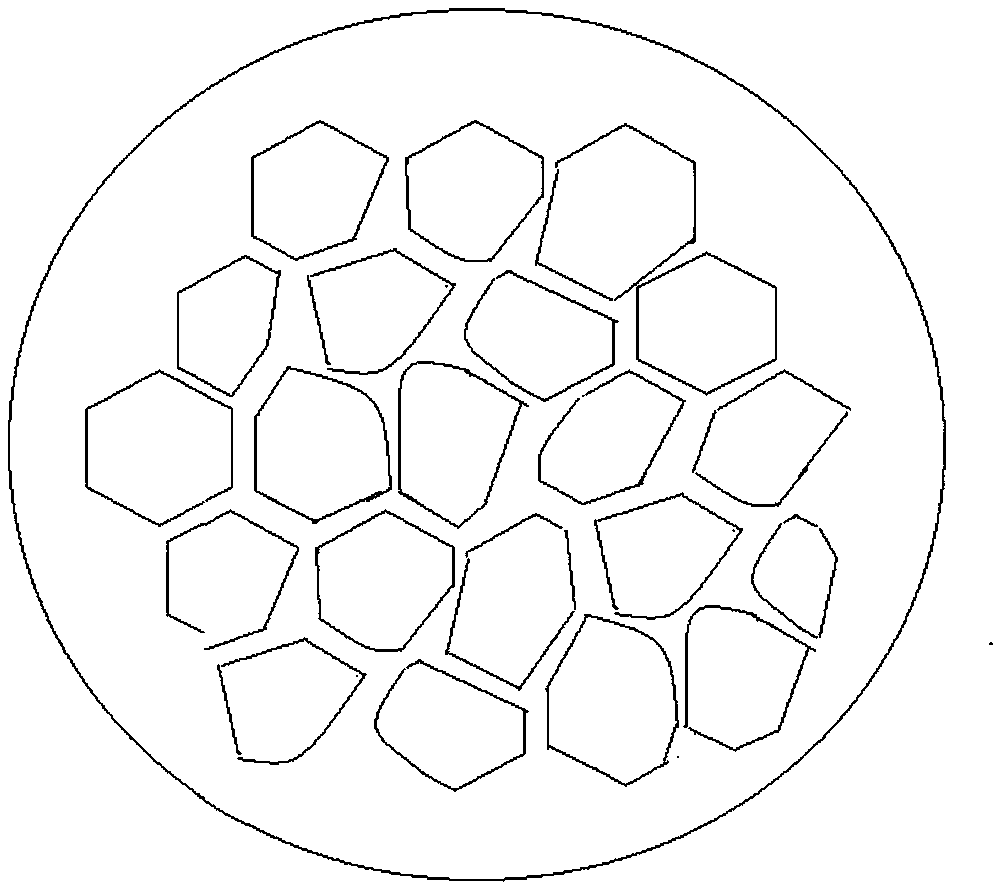

[0031] The NbTi / Cu single-core rod with a copper ratio of 0.8 is stretched and formed into a NbTi / Cu single-core round rod with a diameter of 30mm, and the NbTi / Cu single-core round rod is cut and straightened; the inner diameter is Φ270mm and the wall thickness is processed. Copper sheath with a diameter of 10mm and a length of 1000mm and upper and lower covers with matching dimensions; stretch out copper seam rods with a diameter of Φ2mm, and cut and straighten them; arrange 84 NbTi / Cu single-core round rods closely on the processed copper In the sheath, the triangular gap between all single-core round rods needs to be filled with a copper slot rod with a diameter of 2mm, and the gap between the single-core round rod and the copper sheath is filled with a copper rod with a diameter of 3mm. The welding machine seals and welds the copper sheath and the upper and lower covers to obtain a NbTi / Cu composite sheath; the obtained NbTi / Cu composite sheath is extruded on a 5000t extru...

Embodiment 2

[0034] The NbTi / Cu single-core rod with a copper ratio of 0.8 is stretched into a NbTi / Cu single-core round rod with a diameter of 20mm, and the NbTi / Cu single-core round rod is cut and straightened; the inner diameter is Φ270mm and the wall thickness is processed. 10mm, length 1000mm copper sheath and matching upper and lower covers; pull out a diameter of Φ2mm copper seam rod, and cut and straighten; arrange 144 NbTi / Cu single-core round rods closely on the processed copper In the sheath, the triangular gap between all single-core round rods needs to be filled with a copper slot rod with a diameter of 2mm, and the gap between the single-core round rod and the copper sheath is filled with a copper rod with a diameter of 3mm. The welding machine seals and welds the copper sheath and the upper and lower covers to obtain a NbTi / Cu composite sheath; the obtained NbTi / Cu composite sheath is extruded on a 5000t extruder (extrusion temperature 520°C, extrusion speed 15mm / min, the p...

Embodiment 3

[0037]The NbTi / Cu single-core rod with a copper ratio of 0.8 is stretched and formed into a NbTi / Cu single-core round rod with a diameter of 10mm, and the NbTi / Cu single-core round rod is cut and straightened; the inner diameter is Φ270mm and the wall thickness is processed. Copper sheath with a diameter of 10mm and a length of 1000mm and upper and lower covers with matching dimensions; stretch out a copper seam rod with a diameter of Φ2mm, and cut and straighten it; arrange 630 NbTi / Cu single-core round rods closely on the processed copper In the sheath, the triangular gap between all single-core round rods needs to be filled with a copper slot rod with a diameter of 2mm, and the gap between the single-core round rod and the copper sheath is filled with a copper rod with a diameter of 3mm. The welding machine seals and welds the copper sheath and the upper and lower covers to obtain the NbTi / Cu composite sheath; the obtained NbTi / Cu composite sheath is subjected to extrusion, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com