Filing guide plate for total hip replacement surgery and manufacture and use methods of filing guide plate

A technology for total hip replacement and manufacturing method, which is applied in the field of filing and grinding guides, can solve the problems of lowering the requirements of the doctor's experience and technical level and the deviation of the implantation position of the cup, so as to simplify the filing and grinding operation, avoid the offset, and improve the connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

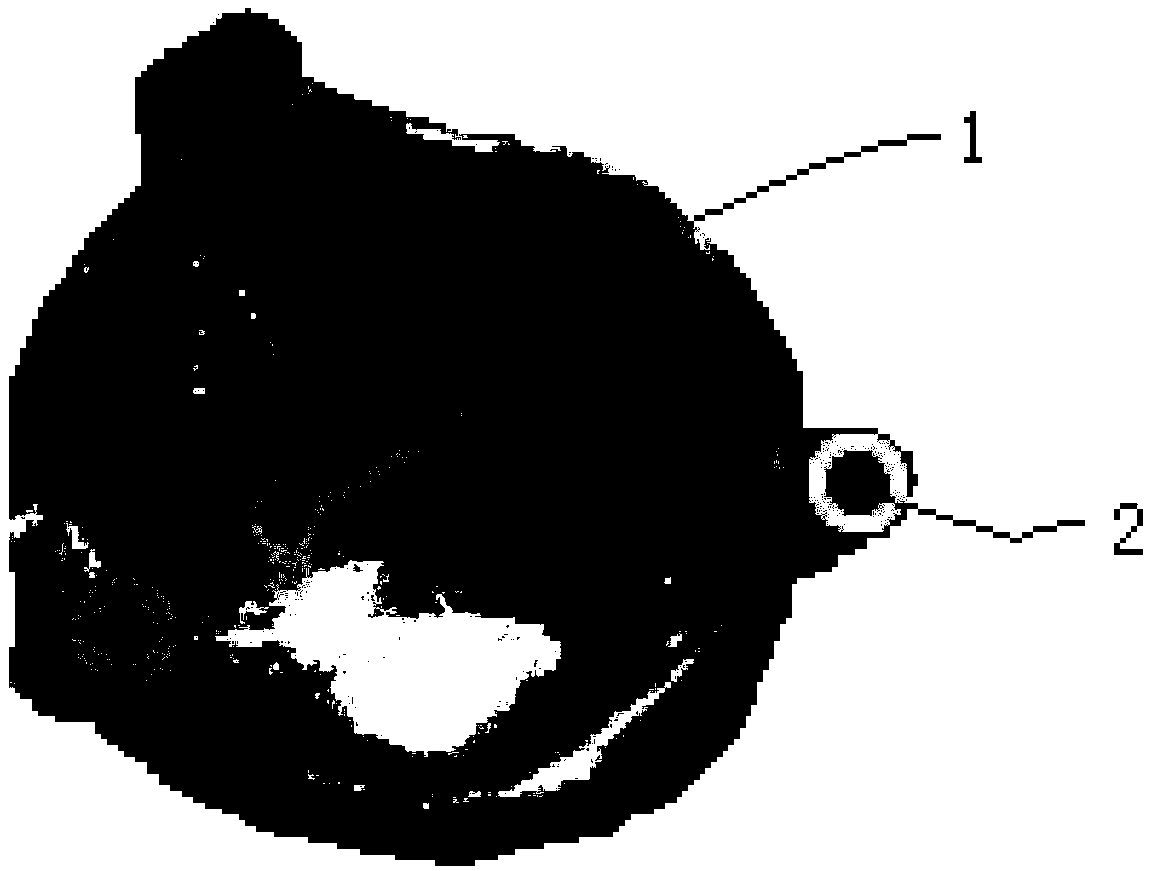

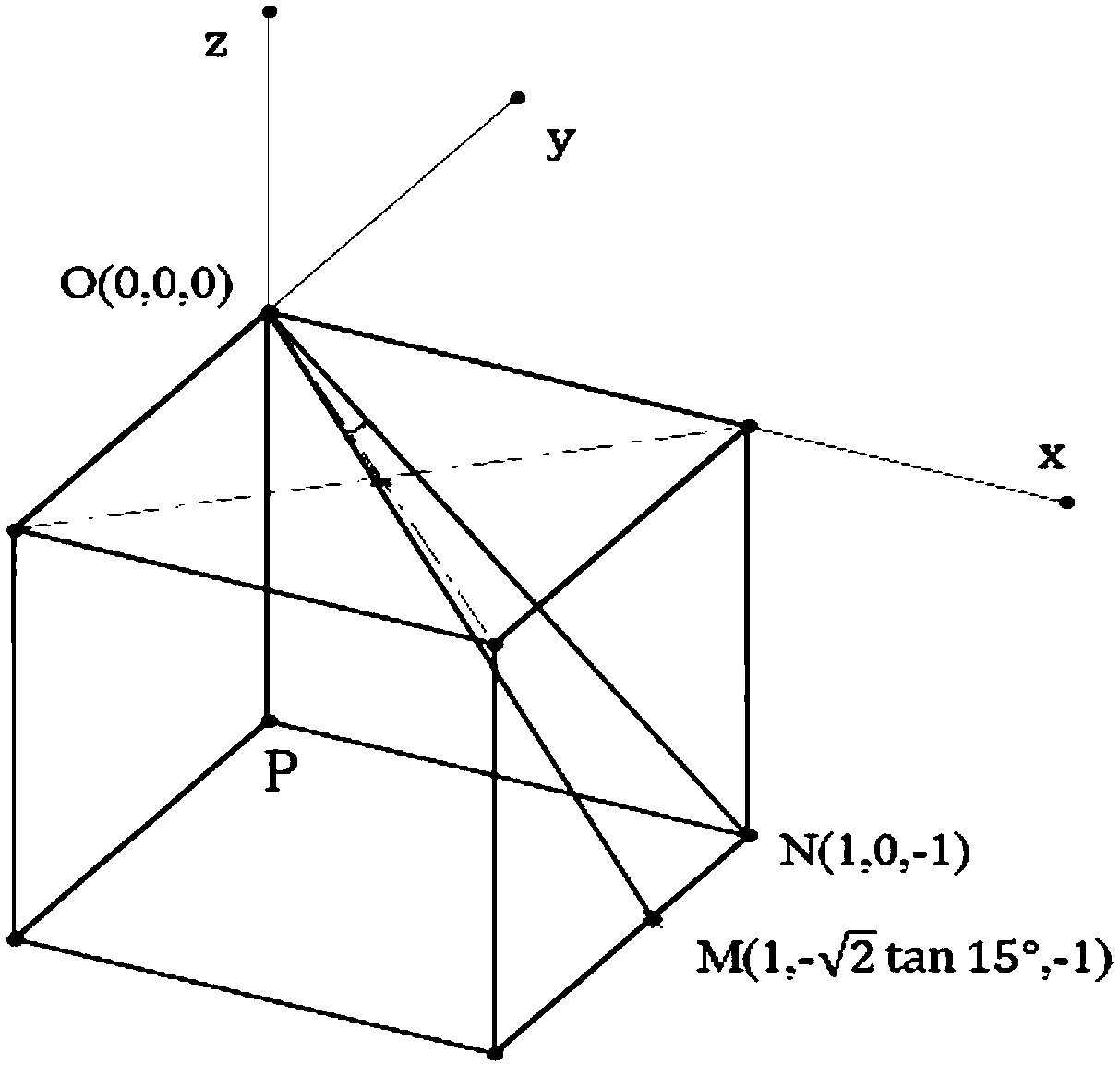

[0034] Such as figure 1 As shown, a rasp guide plate for total hip replacement surgery is characterized in that: it includes a socket-shaped guide plate that is 3D printed according to the three-dimensional model of the patient's acetabular socket, and the printing ratio is 1:1, so that the socket The shaped guide plate has an outer surface that can fit the inner surface of the patient's acetabular socket; there are at least two hollow guide posts evenly distributed along the outer edge of the opening of the socket-shaped guide plate, and the hollow guide posts are fixedly connected to the socket-shaped guide plate; the socket-shaped guide plate After fitting with the inner surface of the acetabular socket, the axis of the hollow guide post can be parallel to the patient's acetabular axis.

[0035] Since the socket-shaped guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com