A plastic packaging bottle for eye drops

A technology for eye drops and packaging bottles, which is applied in the field of pharmaceutical packaging bottles, and can solve problems such as difficulty in pressing the button, poor appearance of the packaging bottle, and small size of the button for extruding eye drops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

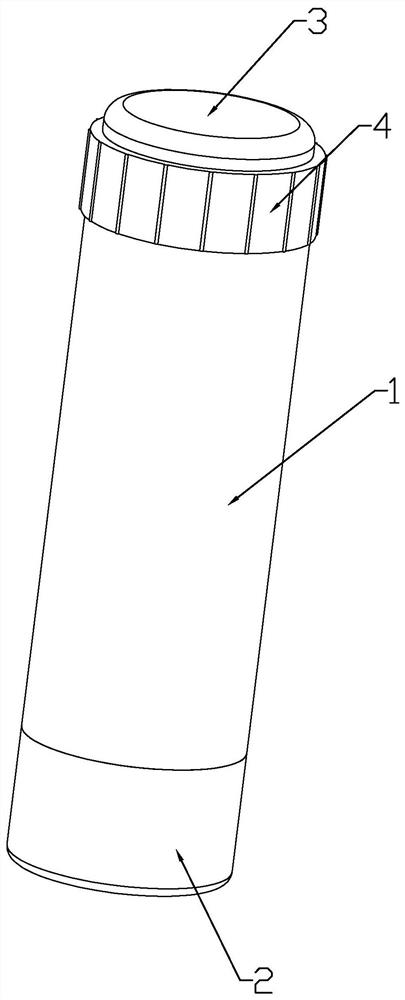

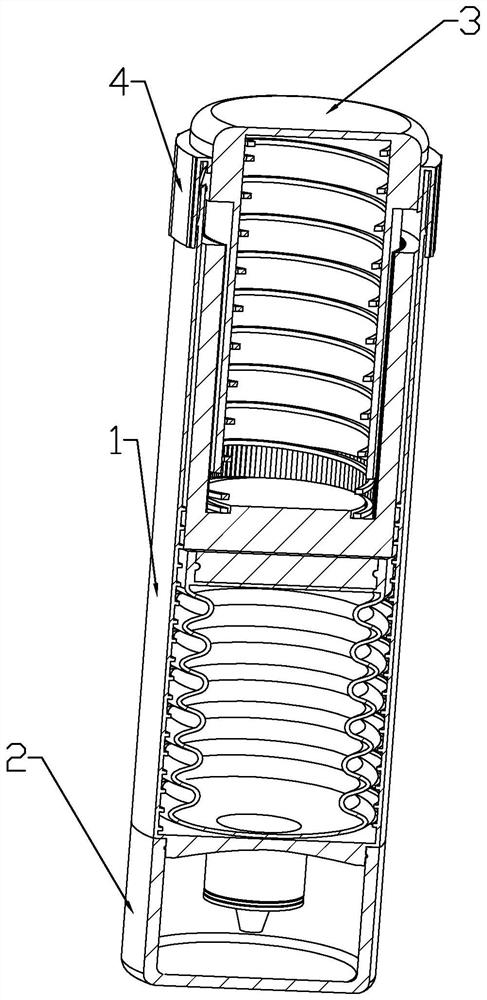

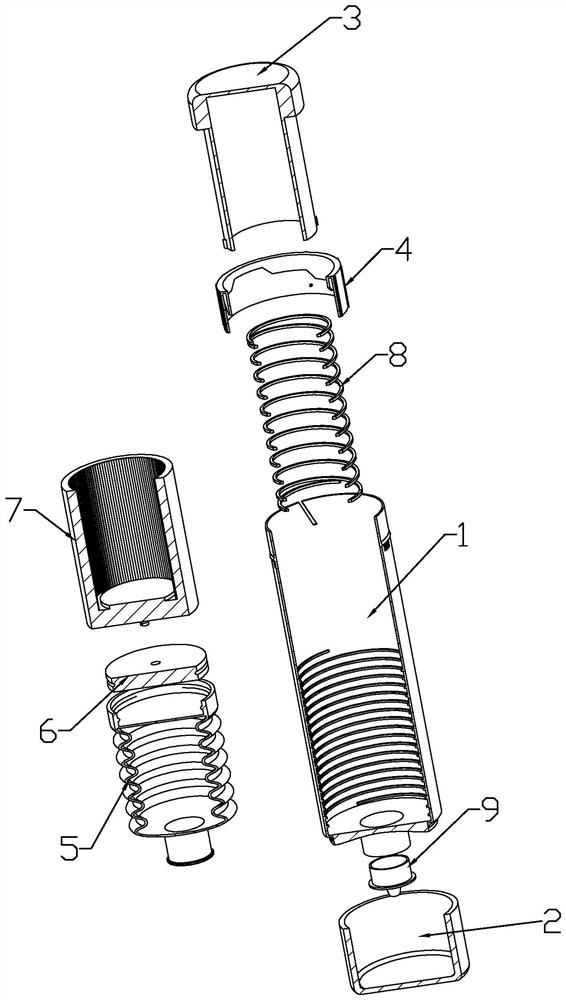

[0031] according to Figure 1 to Figure 9 As shown, a kind of eye drops plastic packaging bottle described in the present embodiment comprises an outer bottle body 1 and a bottle cap 2; a silica gel liner 5 capable of shrinking along the length direction is installed in the outer bottle body 1; The upper end of the silicone liner 5 is a connecting plate 51; the outer periphery of the upper end of the connecting plate 51 is formed with a fixed sleeve 52; the inner wall of the fixed sleeve 52 is formed with an outer convex ring 521; the upper end of the connecting plate 51 is connected with a hard connector 6; The outer wall of the hard connector 6 is formed with an indented groove 62 that engages with the outer flange 521 so that the hard connector and the silicone inner container are fixed to each other;

[0032] The upper end of the har...

Embodiment 2

[0041] In this embodiment, the following improvements are made on the basis of Embodiment 1: a horizontal connecting plate 41 is formed on the inner periphery of the upper end of the limiting nut; an adjusting plate 42 extending vertically downwards is formed on the inner periphery of the connecting plate; The lower end surface of the adjustment plate is formed with a first limiting edge 421 and more than two second limiting edges 422; the adjacent first limiting edge, the second limiting edge, and the adjacent two second limiting edges The height difference between the sides is constant;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com