Selective laser melting device with electromagnetic positioning powder spreading device

A powder spreading device and laser melting technology, applied in the laser field, can solve the problems of low processing efficiency and achieve the effects of avoiding pollution waste, low processing efficiency and large limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

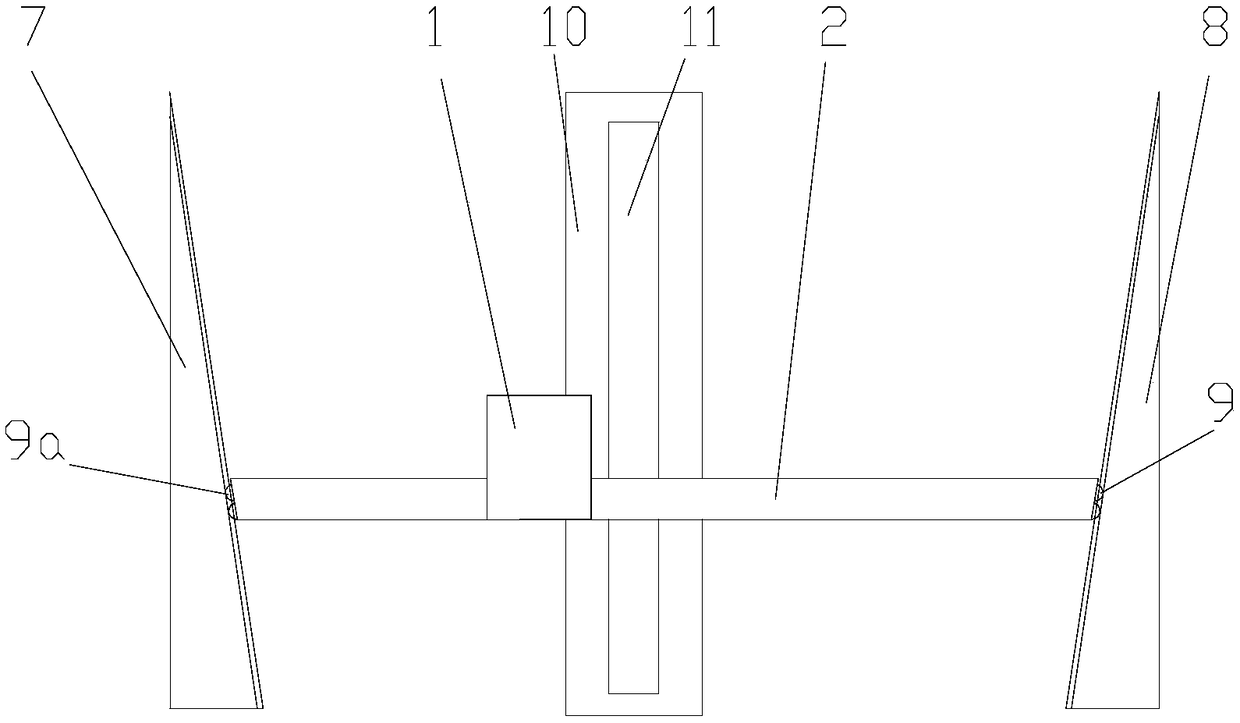

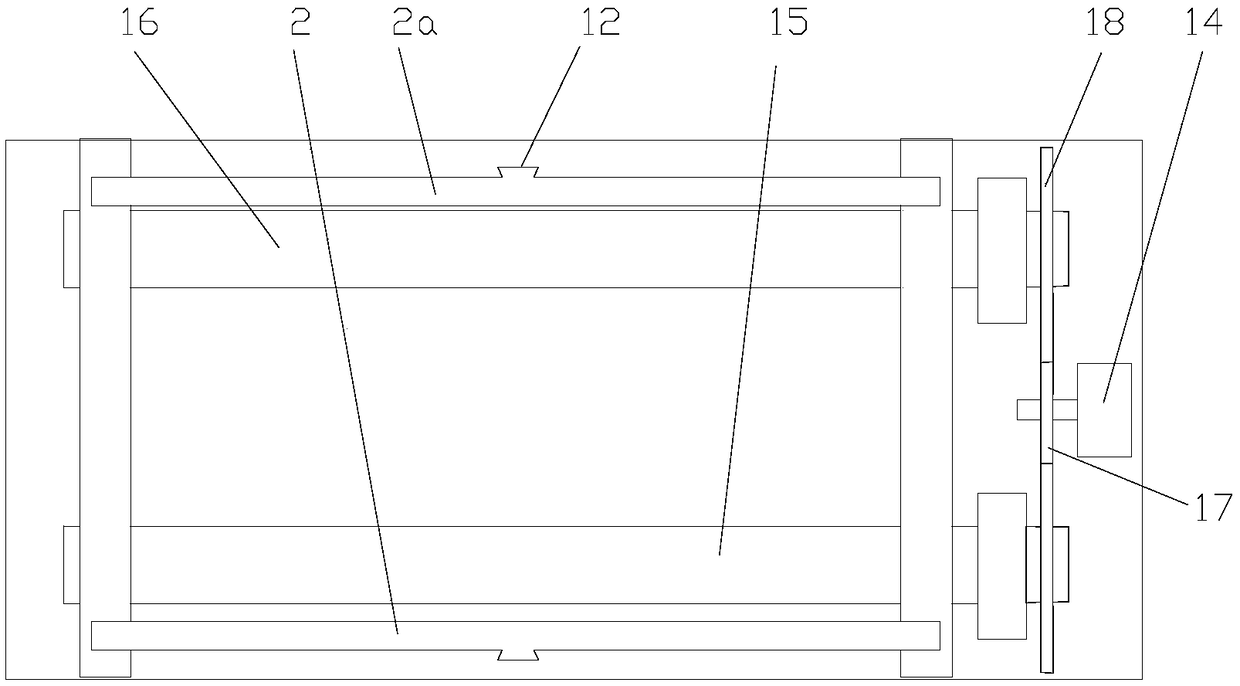

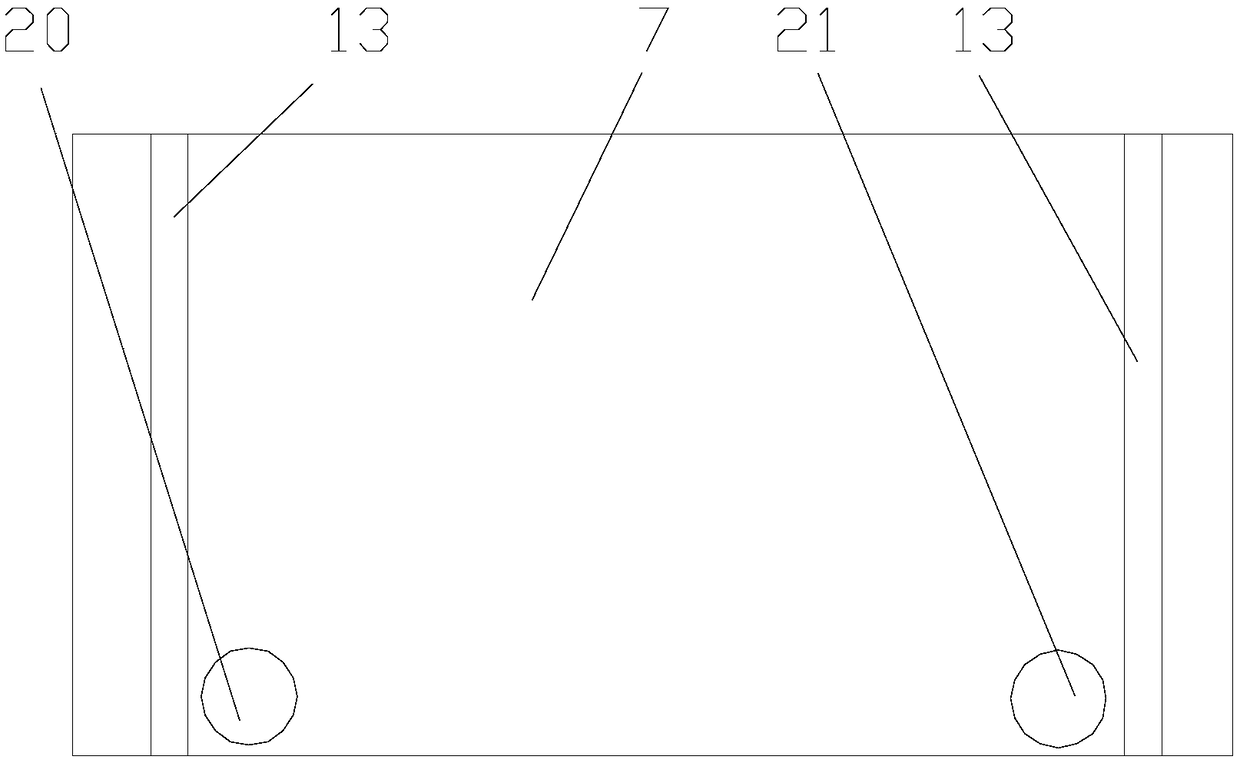

[0029] As shown in the figure, the selective laser melting device with electromagnetic positioning powder spreading device in this embodiment includes a frame (not shown), a powder spreading device 1 for laying metal powder, and a laser for selectively melting metal powder system, a horizontal guide rail for supporting the powder spreading device 1 and a vertical drive mechanism for driving the horizontal guide rail 2 to move vertically. The horizontal drive mechanism, the laser system and the horizontal guide rail 2 are relatively fixed, and the laser is a prior art, so it will not be repeated here; the horizontal guide rail 2 is strip-shaped and its length direction is arranged horizontally, There are two (including the rear horizontal guide rail 2a and the front horizontal guide rail 2) and are respectively located on both sides of the powder spreading device 1 in the longitudinal direction; driven by a horizontal drive motor, the powder spreading device 1 slides in the left...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com