Polishing device for machining expanding and contracting pipe

A polishing device and polishing table technology, applied in the field of machinery, can solve problems such as poor polishing effect of polishing machines, and achieve the effects of avoiding manual transportation, improving quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

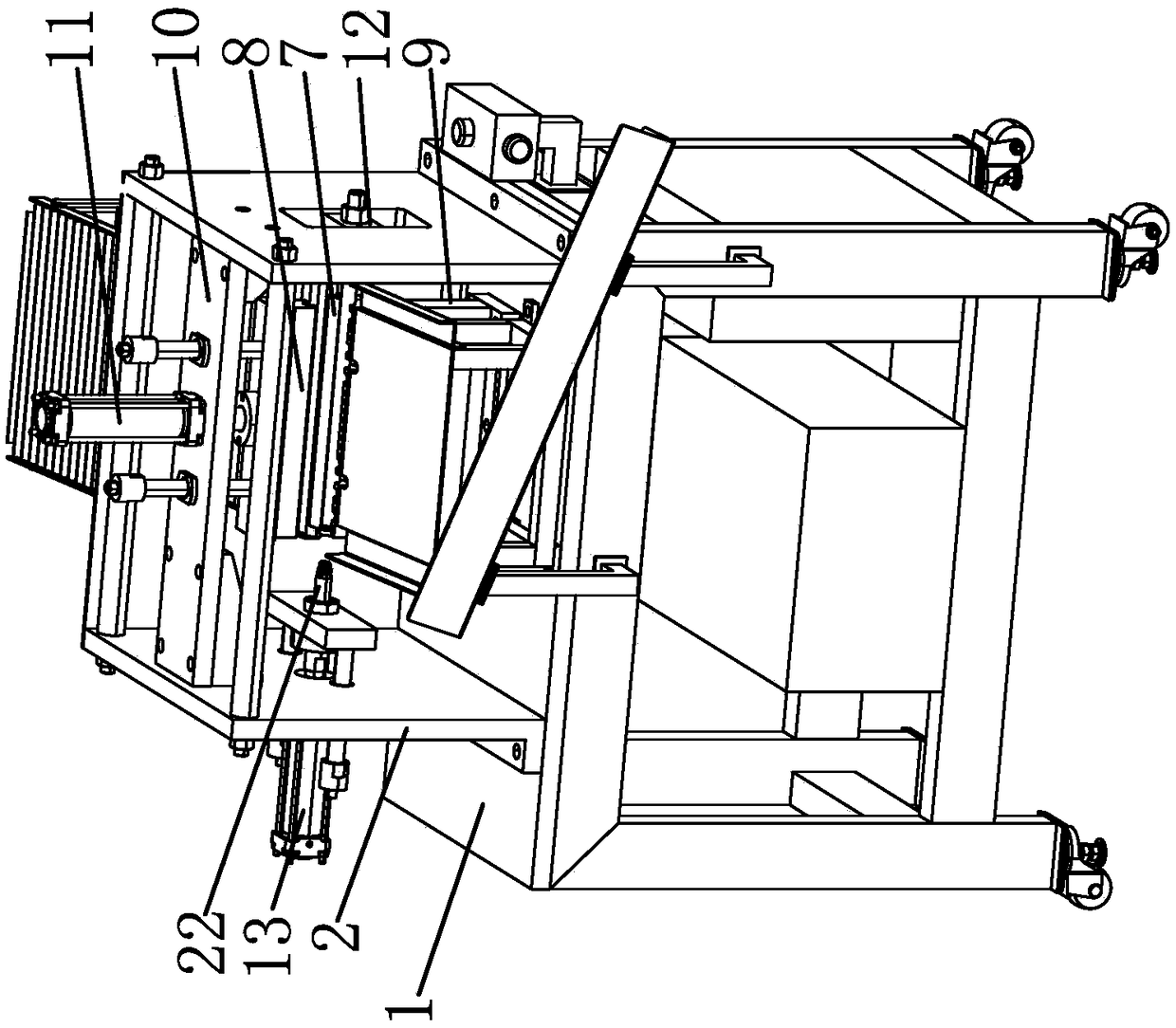

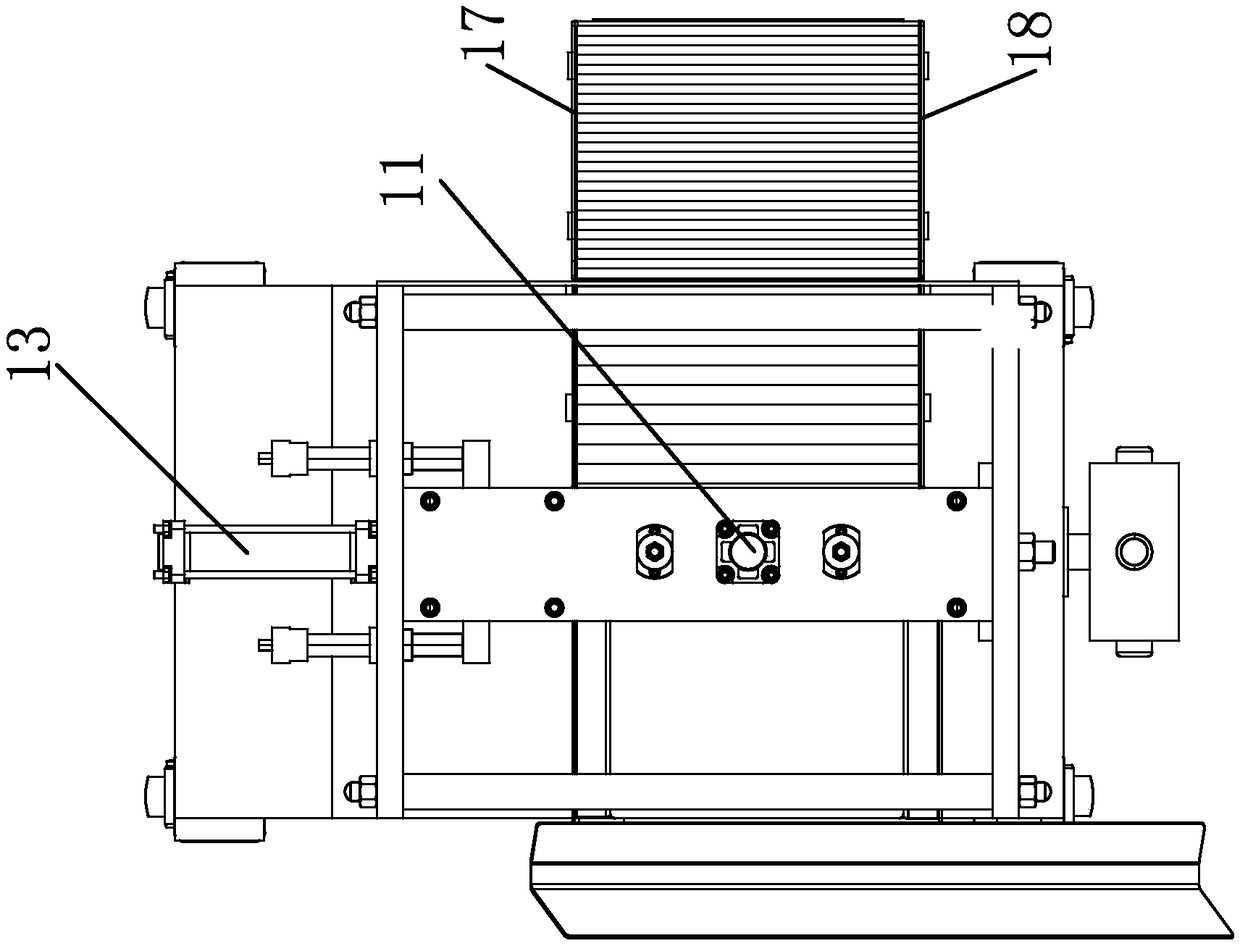

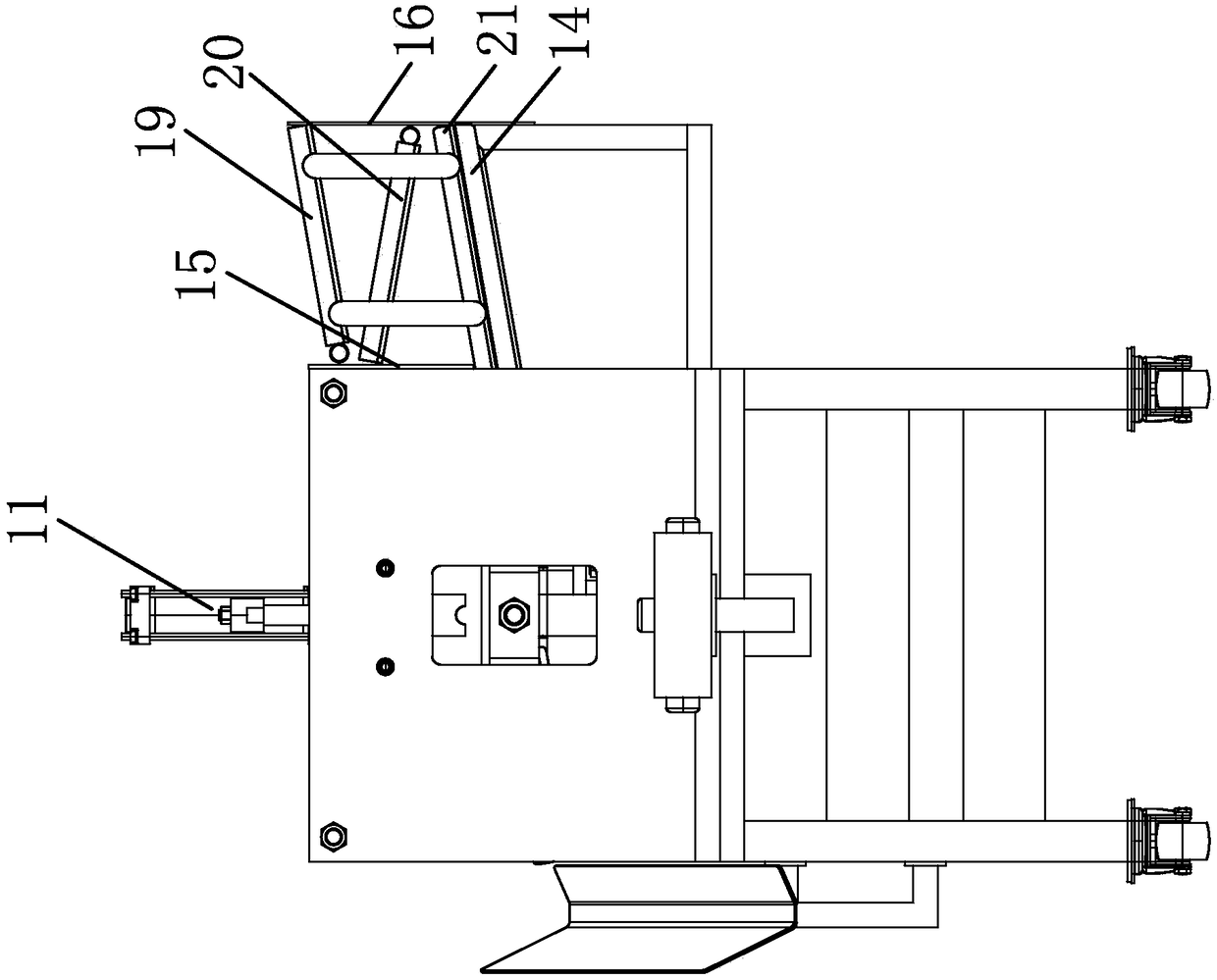

[0027] Such as Figure 1-8 As shown, a production line for processing expansion and contraction tubes includes a frame, and one end of the frame is provided with a tube expansion device capable of processing steel pipes. The tube expansion device includes a workbench 1 on which a bracket 2 is fixed. , the bracket 2 is provided with a pipe expanding mechanism capable of expanding the steel pipe, the rear side of the workbench 1 is provided with a feeding mechanism capable of loading the steel pipe, and the front side of the workbench 1 is provided with a The blanking mechanism; the other end of the frame is provided with a polishing device capable of polishing the expanded steel pipe. The polishing device includes a polishing table, which has a polishing wheel one 3 and a polishing wheel two 4, a polishing wheel one 3 and a polishing wheel two. Polishing wheel 2 4 is arranged oppositely and has a gap for steel pipes to pass through in the middle. Polishing wheel 1 3 is connecte...

Embodiment 2

[0043] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that in Embodiment 1, the driving mechanism includes an oil cylinder 24, and the cylinder body of oil cylinder 24 is fixed on the workbench 1; while in Embodiment 2 Among them, the driving mechanism includes a driving motor, two ejector rods 27 and a guide plate 28, the body of the driving motor is fixed on the workbench 1, the output shaft of the driving motor is facing horizontally and the end is fixed with a cam 29, and the workbench 1 is vertically Guide column 26 is fixed, and guide plate 28 has guide hole, and guide plate 28 is slidably arranged on guide column 26, and push rod 27 is vertically fixed on guide plate 28, and cam 29 leans against the lower surface of guide plate 28, and push rod 27 can pass through hole and drive steel pipe to move upwards. The driving motor work drives the cam 29 to rotate, and the cam 29 rotates to drive the guide plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com