Foldable type combined wing freight aircraft with double-propeller-thrust combined auxiliary wings

A dual-propeller, composite wing technology, applied in the field of aircraft, can solve the problems of high take-off and landing requirements, low safety factor, low safety factor, etc., and achieve the effects of reducing gravitational acceleration, high wing structure strength, and reducing occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

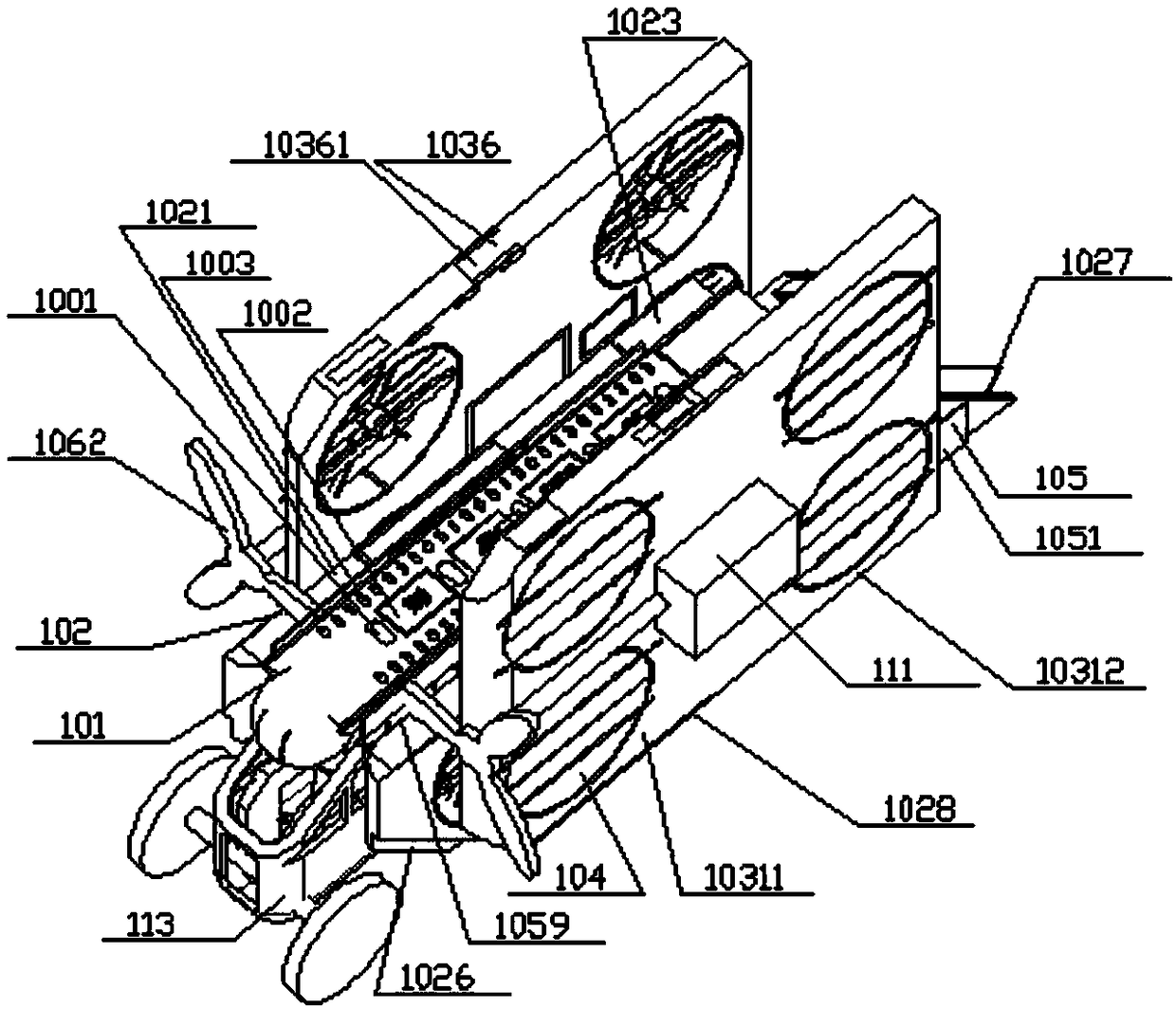

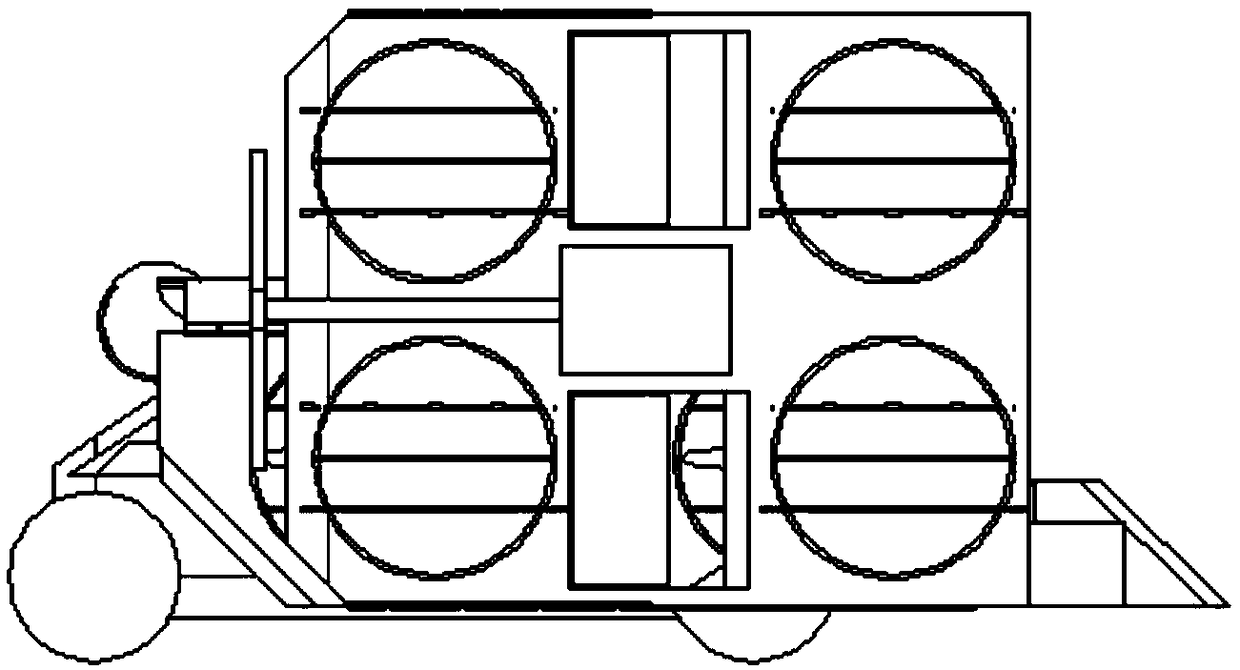

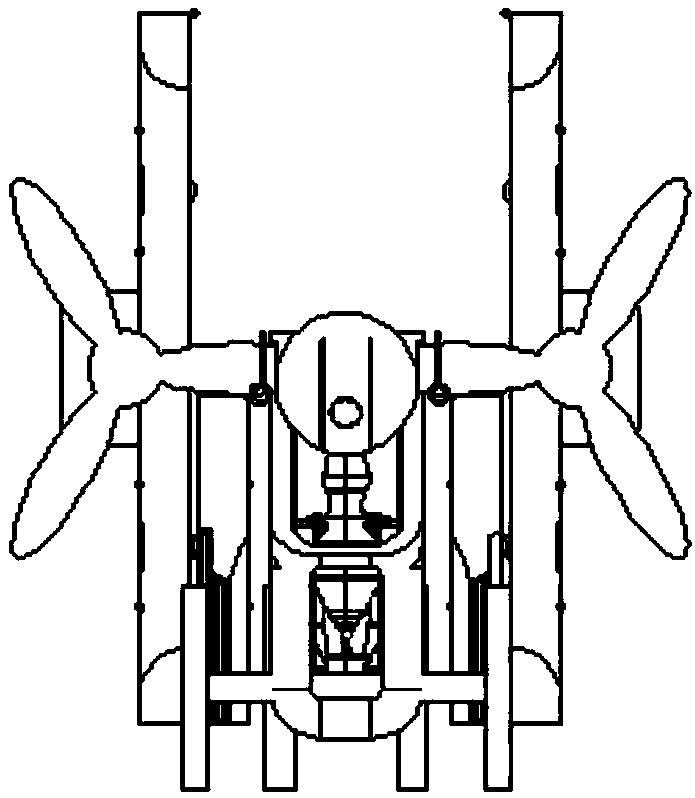

[0033] Such as Figure 1 to Figure 5 As shown, a foldable composite wing cargo aircraft with double propeller thrust compound ailerons consists of a non-rear thrust type composite wing aircraft, a propeller thrust self-powered composite aileron that can be folded and installed on both sides of its wing, and a cargo warehouse 113 Composition; Wherein, described non-rear-thrust type composite wing aircraft comprises body 101, foldable compound lift wing 102 installed on both sides of body 101; Wherein, wherein, described body 101 is set as deck platform; Described composite The lift wing 102 has a built-in self-enclosed ducted fan 104, and the composite lift wing 102 is designed with a wing hinge (1028); The interior of the aileron is provided with a self-enclosed ducted fan 104, and one or both sides of the self-powered compound aileron with propeller thrust are provid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap