A kind of ael structure ceapo-11 molecular sieve and preparation method thereof

A ceapo-11, molecular sieve technology, applied in the direction of molecular sieve and alkali exchange of phosphate, can solve the problems of narrow synthesis range and increased production cost, and achieve the effects of high utilization rate of inorganic atoms, good crystallinity and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

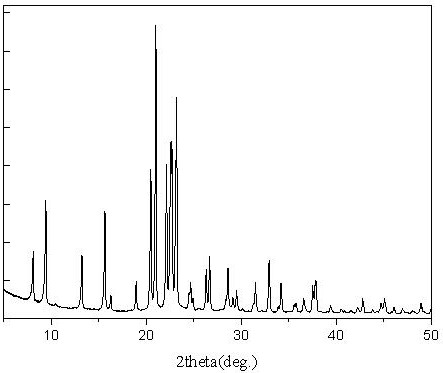

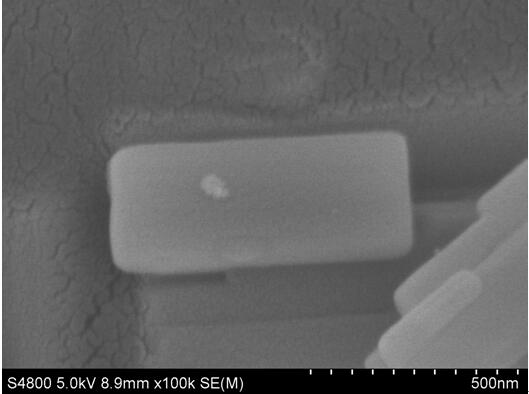

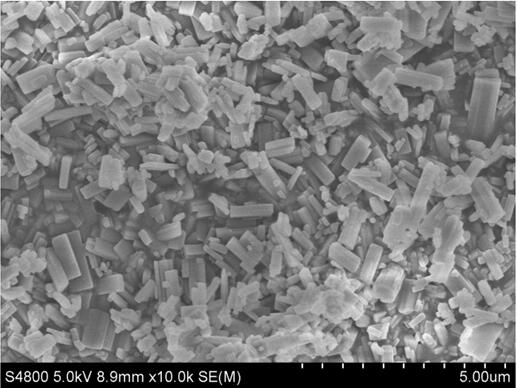

[0025] Such as Figure 1-4 As shown, a CeAPO-11 molecular sieve with AEL structure is composed of metal salt, aluminum source, phosphorus source, cerium source, fluorine source and organic amine template agent, which are mixed into dry powder or granules, followed by crystallization reaction, drying and roasting. Prepared.

[0026] A preparation method of AEL structure CeAPO-11 molecular sieve d, comprising the following steps:

[0027] First, weigh the solid reaction raw materials: 2.084g aluminum isopropoxide, 1.153g phosphoric acid, 0.087g cerium nitrate, 0.205g hydrofluoric acid and 0.607g diisopropylamine, pour them into a mortar, and grind them uniformly for 10-30 minutes. The state of the mixture changes from viscous to wet to dry powder or granules. After the grinding is completed, put it into the reaction kettle and crystallize at 150°C for 8 hours. After the crystallization is completed, cool it at room temperature. After the solid crystallization product is separat...

Embodiment 2

[0031] The preparation method of CeAPO-11 molecular sieve is the same as the addition sequence and grinding time of aluminum isopropoxide, phosphoric acid, cerium nitrate, hydrofluoric acid and diisopropylamine in Example 1, and the chemical molar ratio of this system is: A1 2 o 3 :P 2 o 5 : CeO 2 :F - : R = 1:1:0.04:1:1, put it into the reaction kettle after grinding, crystallize at 150°C for 12h, after the crystallization is complete, cool at room temperature, separate the solid crystal product from the mother liquor, and use deionized water The solid crystalline product was washed to neutrality, the obtained product was fully washed with deionized water, and dried at 80°C, and the utilization rate of its inorganic atoms was 85.5%.

[0032] The rest are the same as embodiment 1.

Embodiment 3

[0034] The preparation method of CeAPO-11 molecular sieve is the same as the addition sequence and grinding time of aluminum isopropoxide, phosphoric acid, cerium nitrate, hydrofluoric acid and diisopropylamine in Example 1. The chemical ratio of the system is as follows: A1 2 o 3 :P 2 o 5 : CeO 2:F - : R = 1:1:0:1:1, crystallized at 150°C for 12h. After the reaction was completed, the obtained product was thoroughly washed with deionized water and dried at 80 °C.

[0035] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com