Air suction type composting reactor

A composting reactor and reactor technology are applied in the field of composting reactors, which can solve the problems of unsatisfactory discharge effect, low gas concentration and low concentration, and achieve the effects of simple structure, solving gas leakage and increasing concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

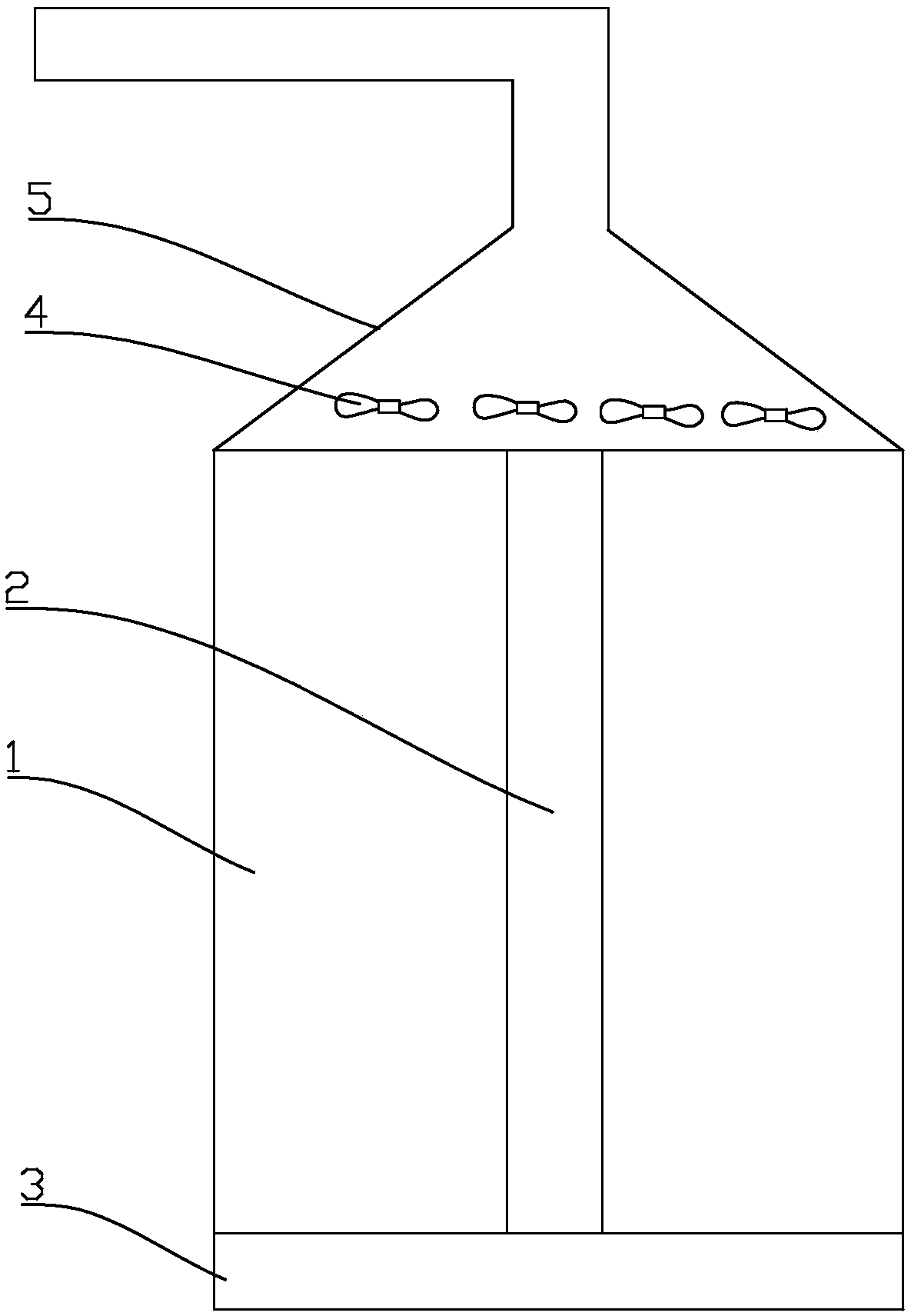

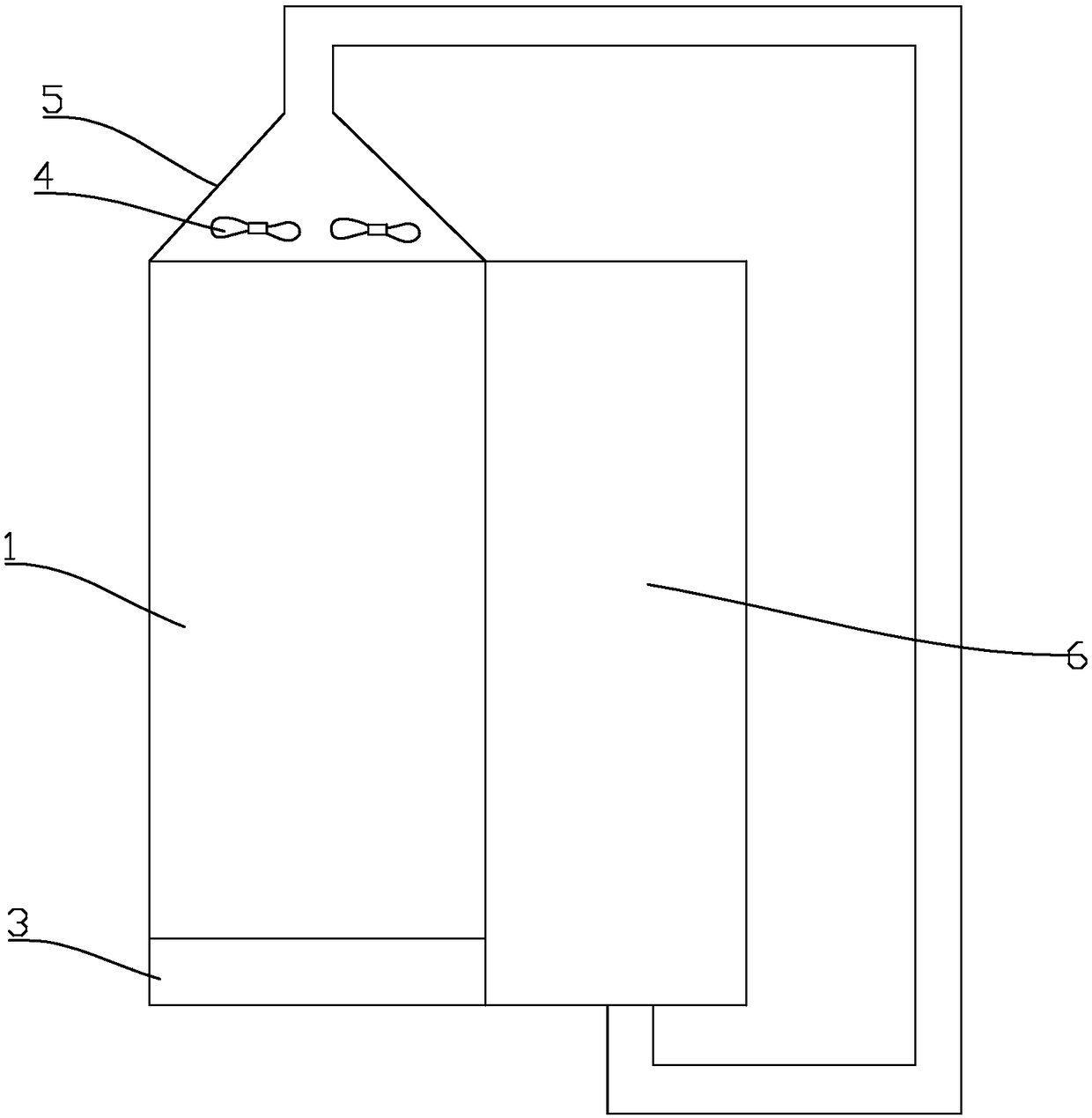

[0017] refer to figure 1 and figure 2 , the present invention is a draft type composting reactor, comprising a reactor tank 1, the lower end of the reactor tank 1 is provided with an air inlet 3, and the upper end of the reactor tank 1 is provided with an air exhaust port, the exhaust The tuyere is provided with an air extraction device.

[0018] In order to facilitate the introduction of air into the compost, the reactor tank 1 is provided with an air passage 2, and several reaction chambers are arranged around the air passage 2, and a guide plate is provided in the air passage 2, and the air guide The plates are used to direct air to the reaction chamber. Due to the effect of the air extraction device, the air is conveyed from bottom to top along the air inlet 3. Therefore, several deflectors are arranged obliquely corresponding to different reaction chambers, so that the upper end of the deflector is close to the reaction chamber, and the lower end is away from the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com