Preparation method of zirconium acetate

A technology of zirconium acetate and acetic acid, which is applied in the field of preparation of zirconium acetate, can solve the problems of unclear dissolution and high NTU of zirconium acetate, and achieve the effect of less impurities and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

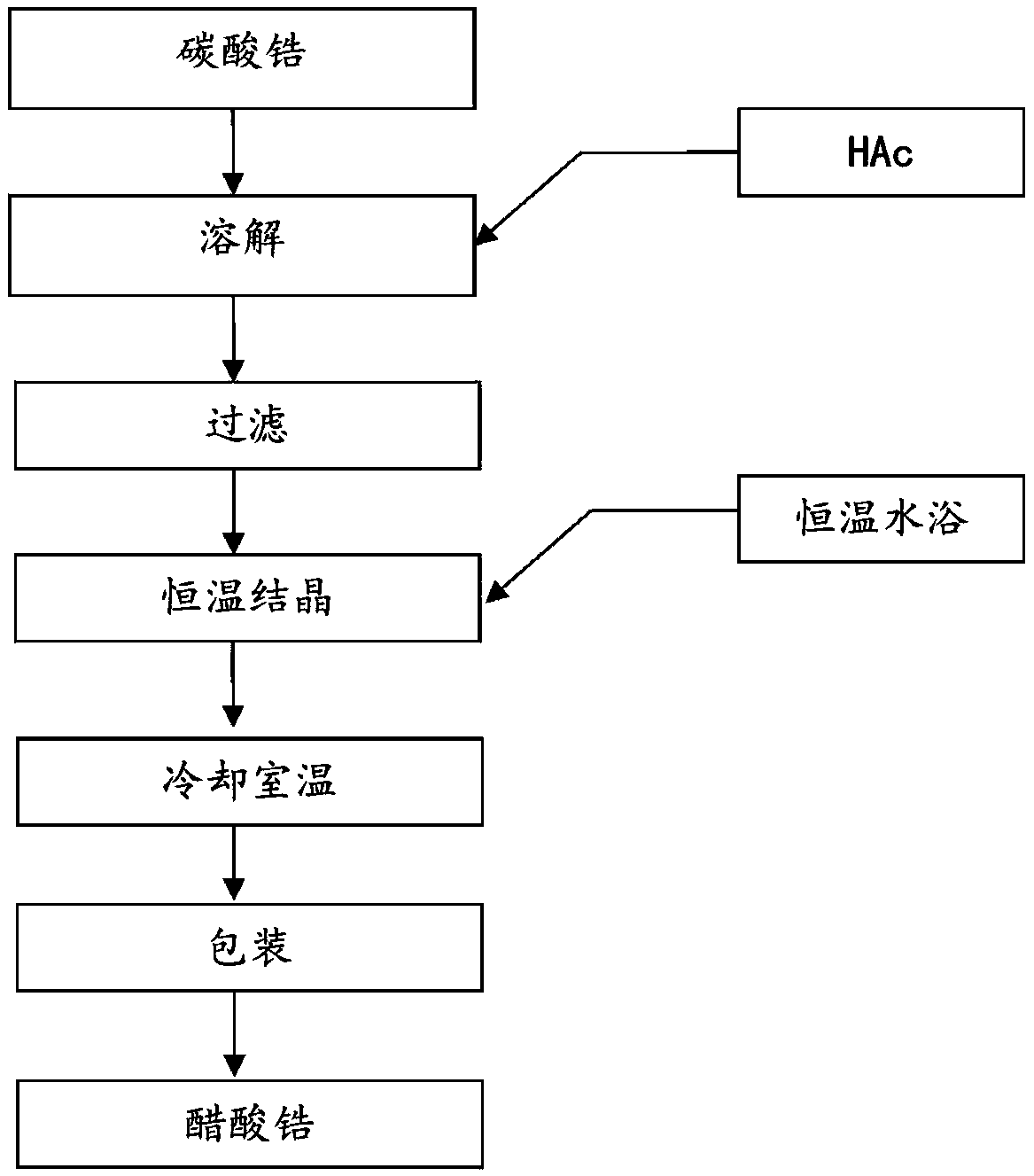

Image

Examples

Embodiment 1

[0022] A kind of preparation method of zirconium acetate, specifically comprises the following steps:

[0023] (1) drop into 1000Kg zirconium carbonate in the enamel reactor;

[0024] (2) Add 750Kg of acetic acid to the enamel reaction kettle of step (1), and then use steam to heat the enamel reaction kettle to increase the temperature of the kettle; ℃; during the heat preservation process, repeated sampling and observation, until completely dissolved and clear, to obtain zirconium acetate solution;

[0025] (3) the zirconium acetate solution obtained in the step (2) is first filtered through 200 mesh filter cloths to obtain the first filtrate, and then the first filtrate is used to obtain the filtrate after two stages of filtration using a microporous filter with an aperture of 1 μm;

[0026] (4) Put the filtrate obtained in step (3) into a crystallization tray, then evaporate and crystallize for 130 hours in a water bath at a constant temperature of 90°C;

[0027] (5) Pack...

Embodiment 2

[0032] A kind of preparation method of zirconium acetate, specifically comprises the following steps:

[0033] (1) drop into 800Kg zirconium carbonate in the enamel reactor;

[0034] (2) Add 600Kg of acetic acid to the enamel reaction kettle of step (1), and then use steam to heat the enamel reaction kettle to increase the temperature of the kettle; when the temperature of the kettle rises to 60°C, stop heating and maintain the temperature of the kettle at 60±2 ℃; during the heat preservation process, repeated sampling and observation, until completely dissolved and clear, to obtain zirconium acetate solution;

[0035] (3) the zirconium acetate solution obtained in the step (2) is first filtered through 200 mesh filter cloths to obtain the first filtrate, and then the first filtrate is used to obtain the filtrate after two stages of filtration using a microporous filter with an aperture of 5 μm;

[0036] (4) Put the filtrate obtained in step (3) into a crystallization tray, a...

Embodiment 3

[0042] A kind of preparation method of zirconium acetate, specifically comprises the following steps:

[0043] (1) drop into 900Kg zirconium carbonate in the enamel reactor;

[0044] (2) Add 675Kg of acetic acid to the enamel reaction kettle of step (1), and then use steam to heat the enamel reaction kettle to increase the temperature of the kettle; ℃; during the heat preservation process, repeated sampling and observation, until completely dissolved and clear, to obtain zirconium acetate solution;

[0045] (3) the zirconium acetate solution obtained in the step (2) is filtered through 200 mesh filter cloths earlier to obtain the first filtrate, and then the first filtrate is used to obtain the filtrate after the two-stage filtration of the microporous filter with an aperture of 3 μm;

[0046] (4) Put the filtrate obtained in step (3) into a crystallization tray, then evaporate and crystallize for 160 h under a constant temperature condition of a water bath at 95° C.;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com