A CSTR fermentation tank discharge system and process for mixing multiple raw materials

A discharge system and fermenter technology, which is applied to specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biomass post-treatment, etc., can solve the problem of overflow pipes and sludge discharge pipes being damaged by fibers and Problems such as clogging of crystalline substances, inability to achieve gravity sludge discharge, inability to apply CSTR fermentation tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

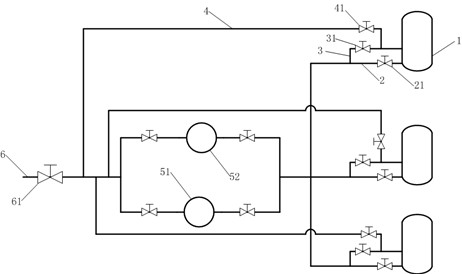

[0024] Multiple CSTR fermenter 1 sludge discharge systems are connected together and connected to the sludge discharge power system. The sludge discharge power system in this embodiment is a screw pump, and the number of screw pumps is usually a plurality of parallel layouts. Calculate the number of screw pumps according to the total anaerobic volume and fermentation time of multiple CSTR fermenters 1. Preferably, the number of screw pumps can be arranged according to the mode of dual use and one standby. As a typical implementation, this embodiment is described according to the layout of two screw pumps, which are respectively the first screw pump 51 and the second screw pump 52. The upstream and downstream of each screw pump have valves respectively, which can control the screw pump. Power direction is controlled.

[0025] Each CSTR fermentation tank 1 has a return pipe 4, the end of the return pipe 4 is connected to the downstream of the screw pump and realizes the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com