Online critical spheroidizing annealing method of GCr15 bearing steel

A spheroidizing annealing and bearing steel technology, applied in the field of metallurgical materials, can solve problems such as affecting production efficiency, increasing energy consumption, and long production cycle, saving energy, avoiding the formation of carbide network structures, and inhibiting carbides. Precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

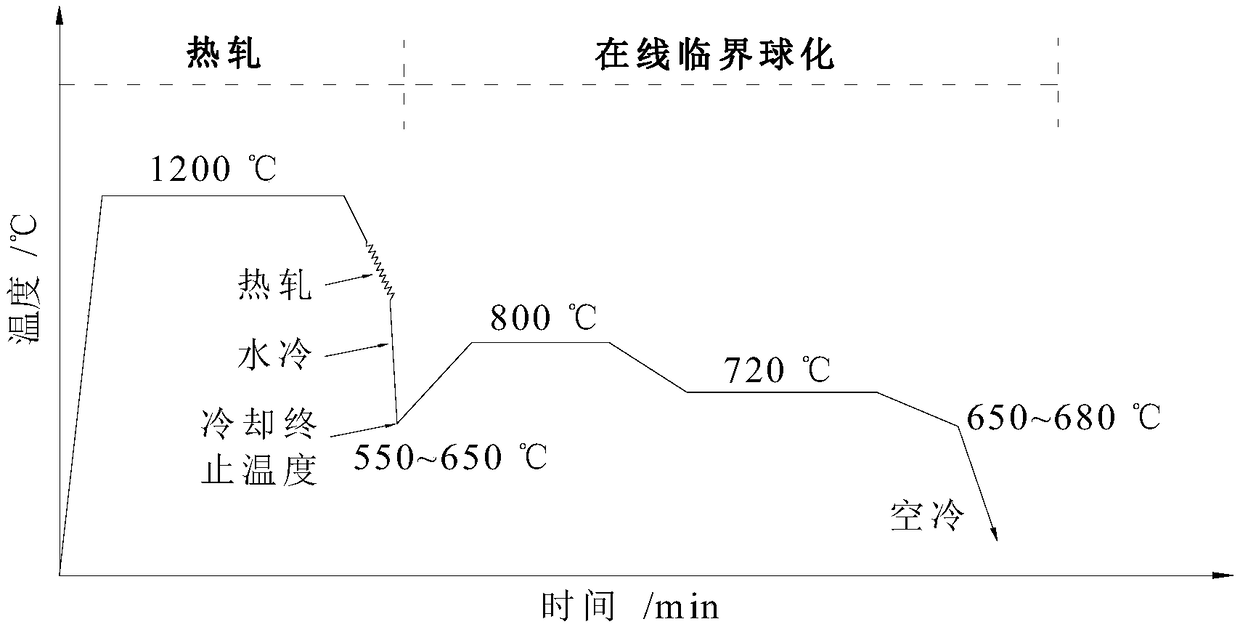

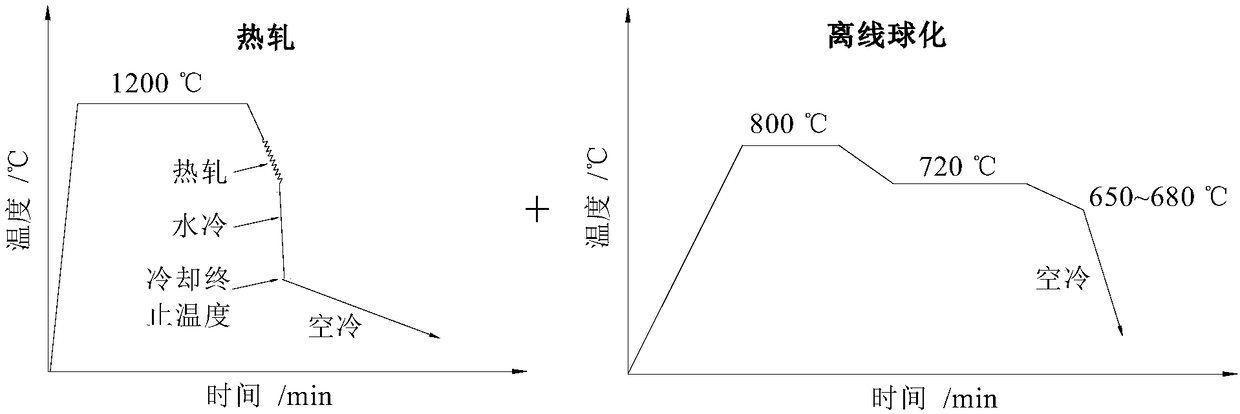

[0027] The GCr15 bearing steel continuous casting slab selected in the embodiment of the present invention is divided into six groups, and the first group, the second group, the third group and the fourth group are spheroidized according to the online critical spheroidization method described in the present invention. A schematic diagram of the process curve used is shown in figure 1 shown. For comparison, the fifth group and the sixth group performed conventional off-line spheroidizing annealing, and the schematic diagram of the process curve is as follows figure 2 shown.

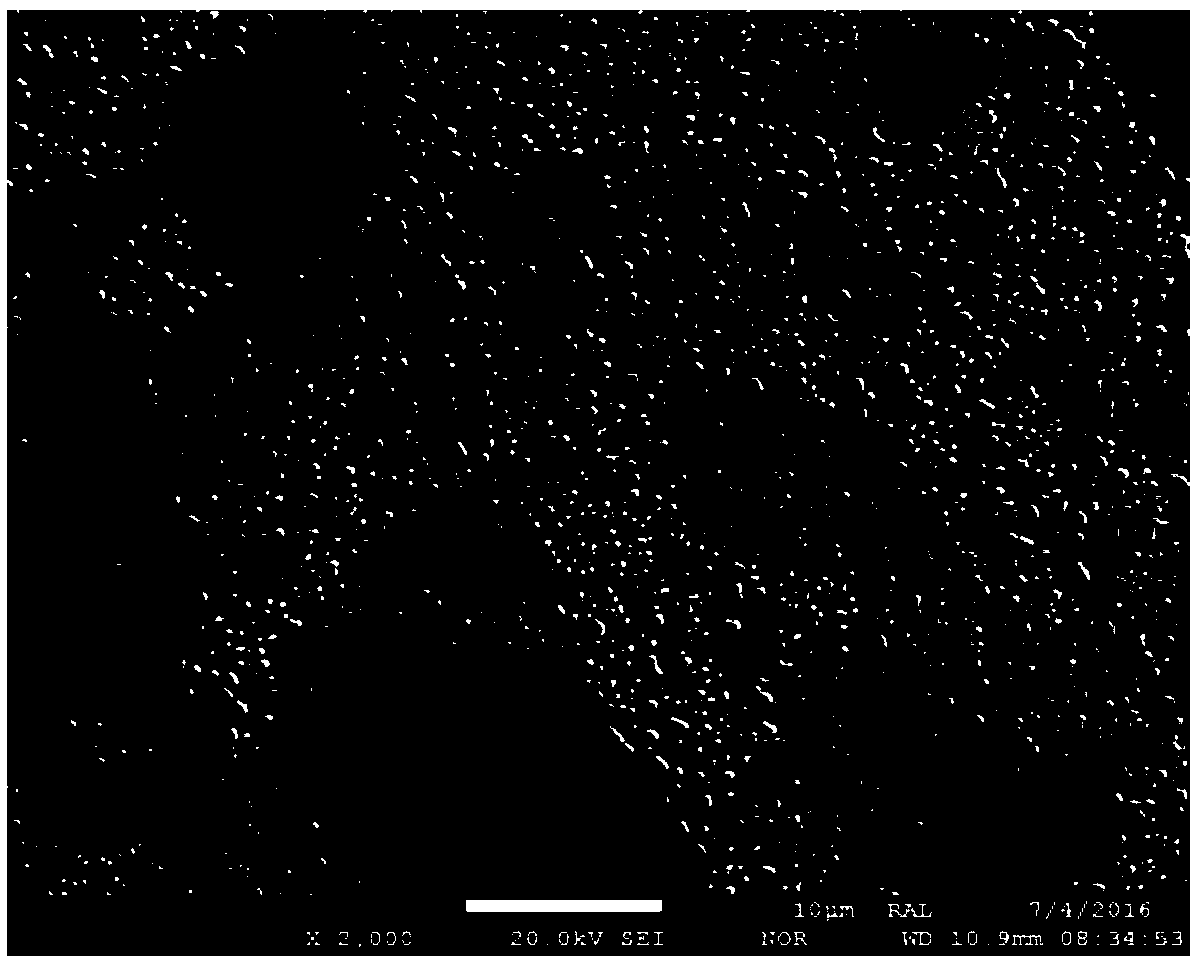

[0028] In the embodiment of the present invention, an electron probe (JEOL JXA-8530F) is used to observe the microstructure. The embodiment of the present invention follows the standard metallographic preparation method: use No. 240, 600, 800, 1000, 1200 and 1500 sandpaper to grind the bearing steel surface perpendicular to the rolling direction; use water-soluble diamond abrasive paste to polish. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com