Construction Method of Core Soil at the Upper Part of Tunnel Micro-three Steps

A core soil, three-step technology, applied in tunnels, tunnel linings, earthwork drilling, etc., to control deformation and damage, ensure construction safety, and shorten the ring formation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

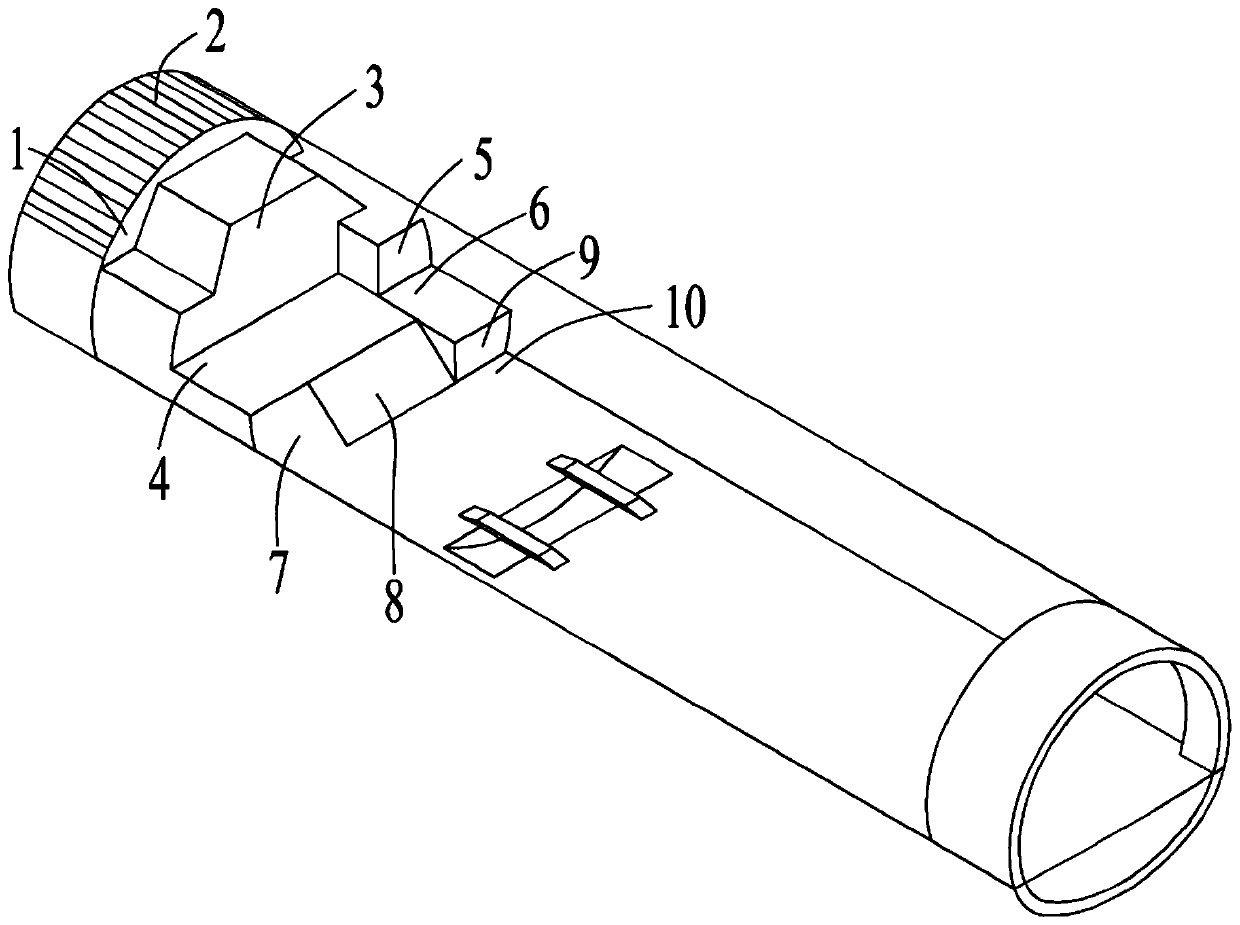

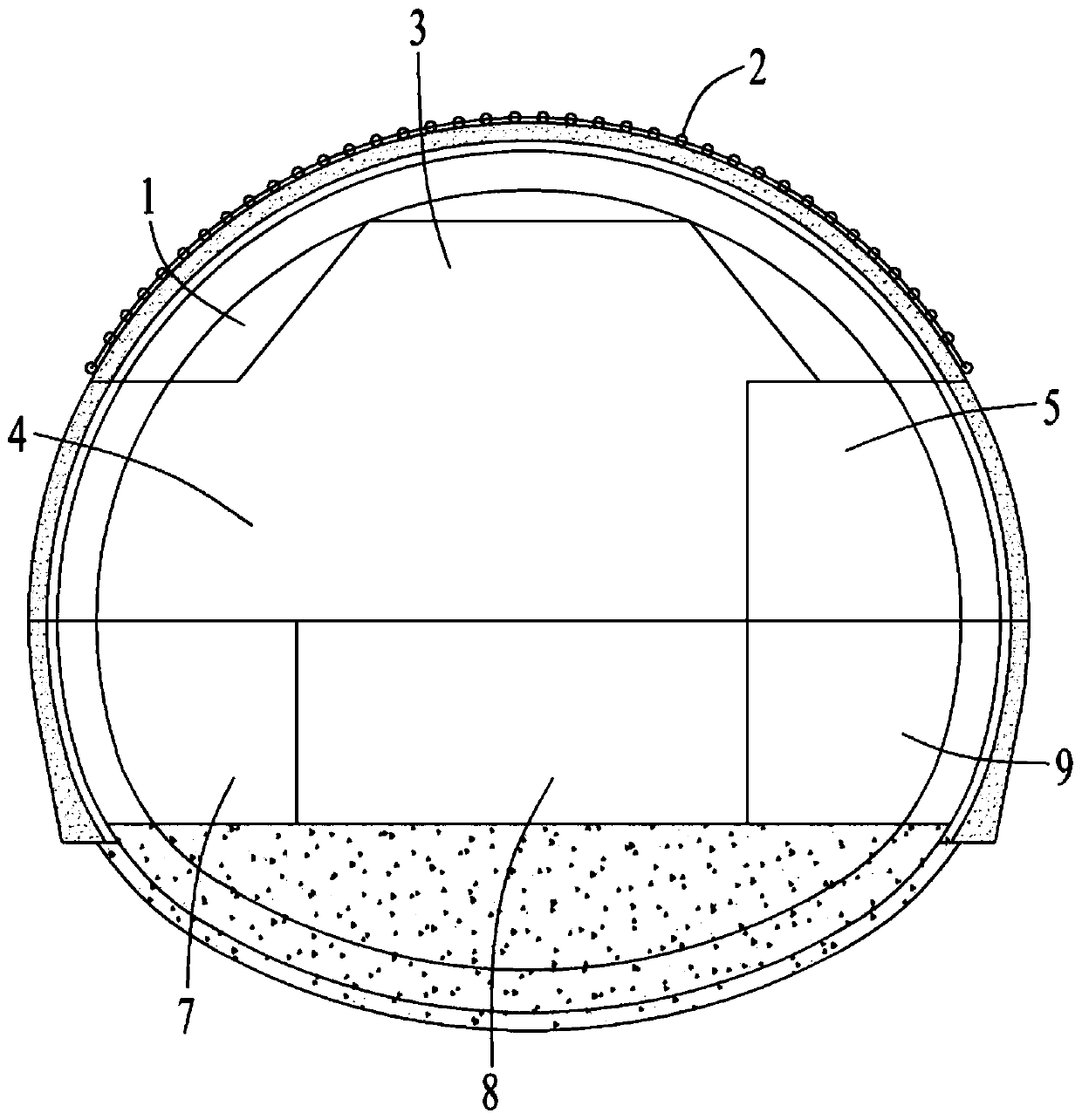

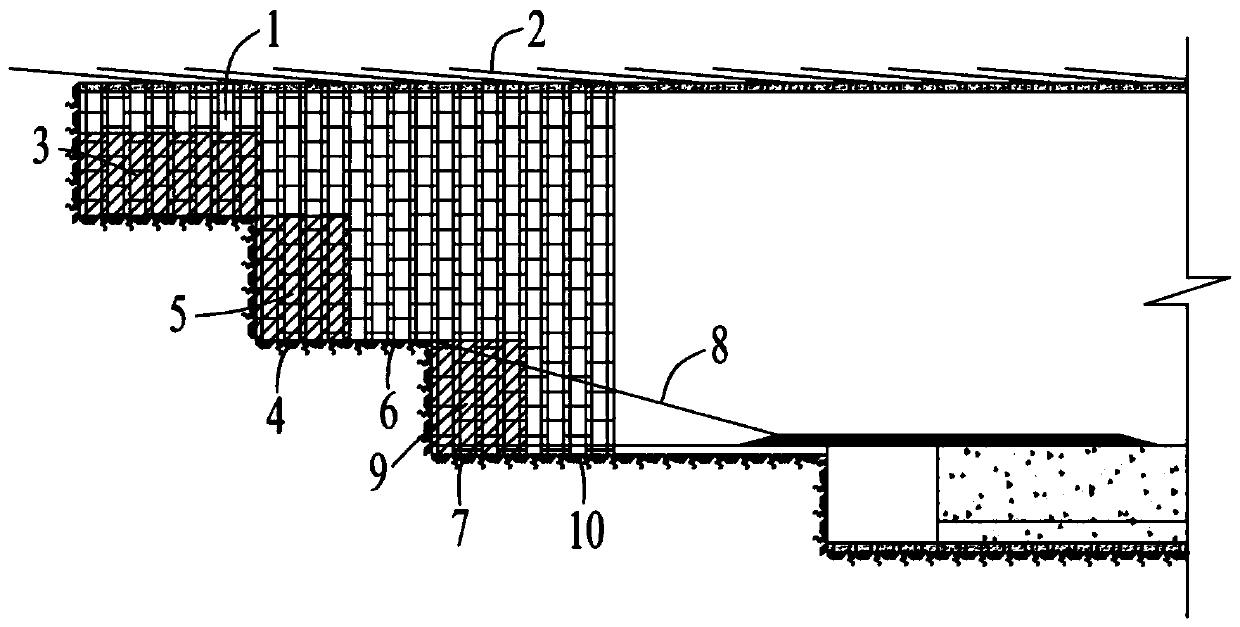

[0036] see Figure 1 to Figure 3 , the present invention provides a construction method for the core soil at the upper part of the micro three steps of the tunnel, the construction method includes the following steps:

[0037] Step 1, excavation of the upper step 1: perform arch support 2 in advance, excavate the upper step 1, the excavation height of the upper step 1 is about 4m, and the excavation span ratio of the upper step 1 should be greater than 0.3. During construction, the upper step 1 arc-shaped pilot pit is excavated in a circular direction, and the upper core soil 3 is retained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com