A rv reducer with large reduction ratio

A technology of large reduction ratio and reducer, which is applied in mechanical equipment, transmission devices, gear transmission devices, etc., can solve the problems that the size of the planetary gear should not exceed the maximum installation size of the reducer, the large reduction ratio, and the difficulty in obtaining. The effect of saving axial length, low starting torque and low vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

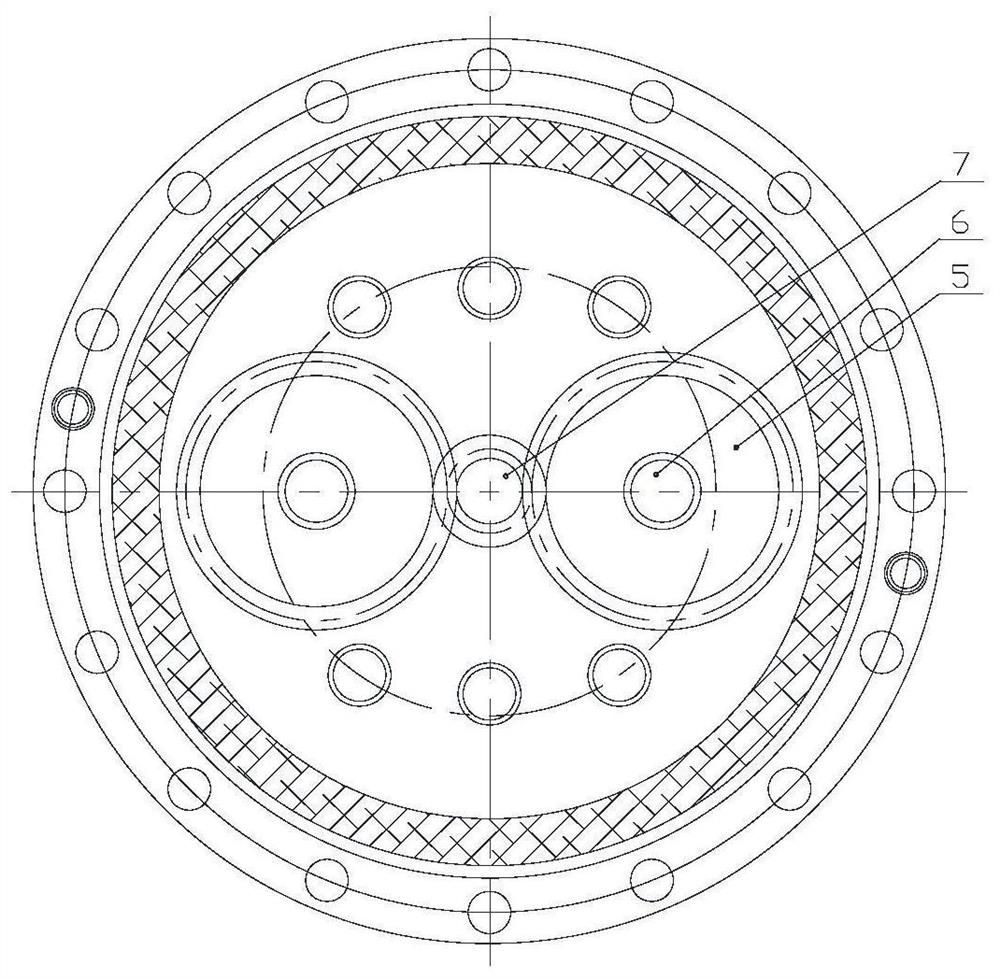

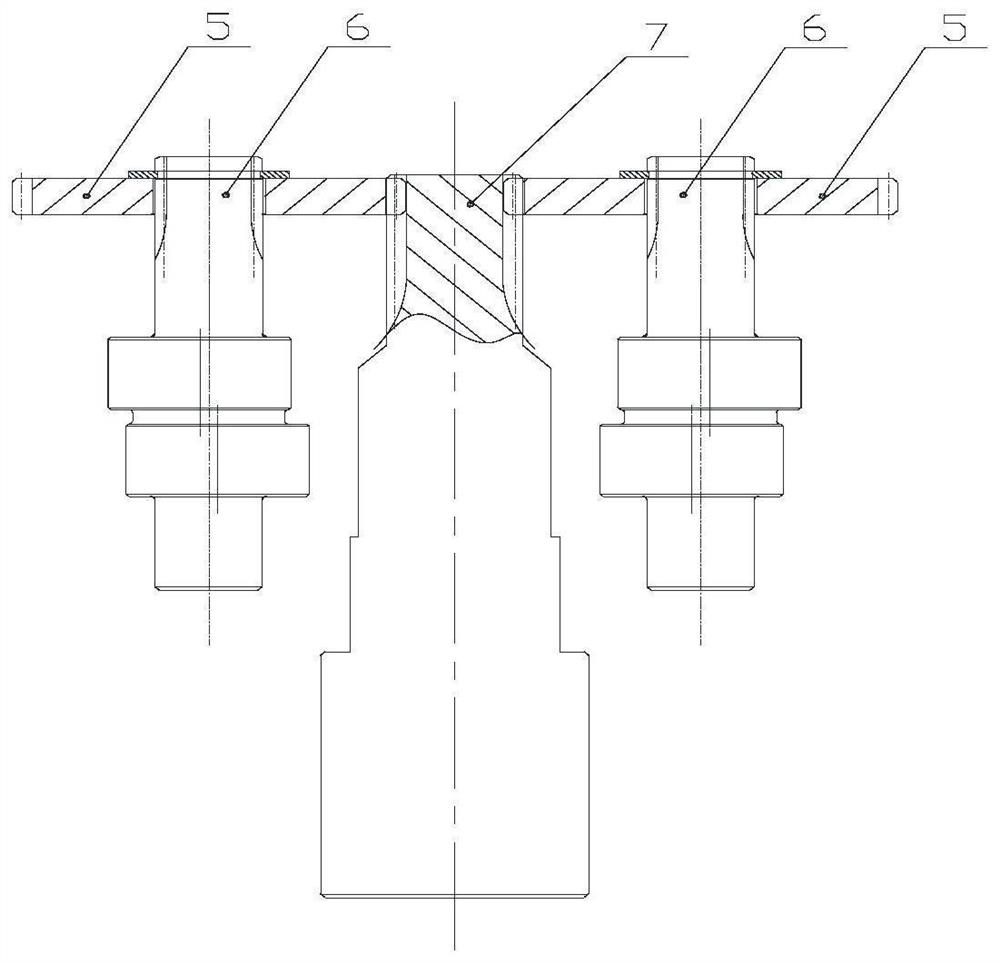

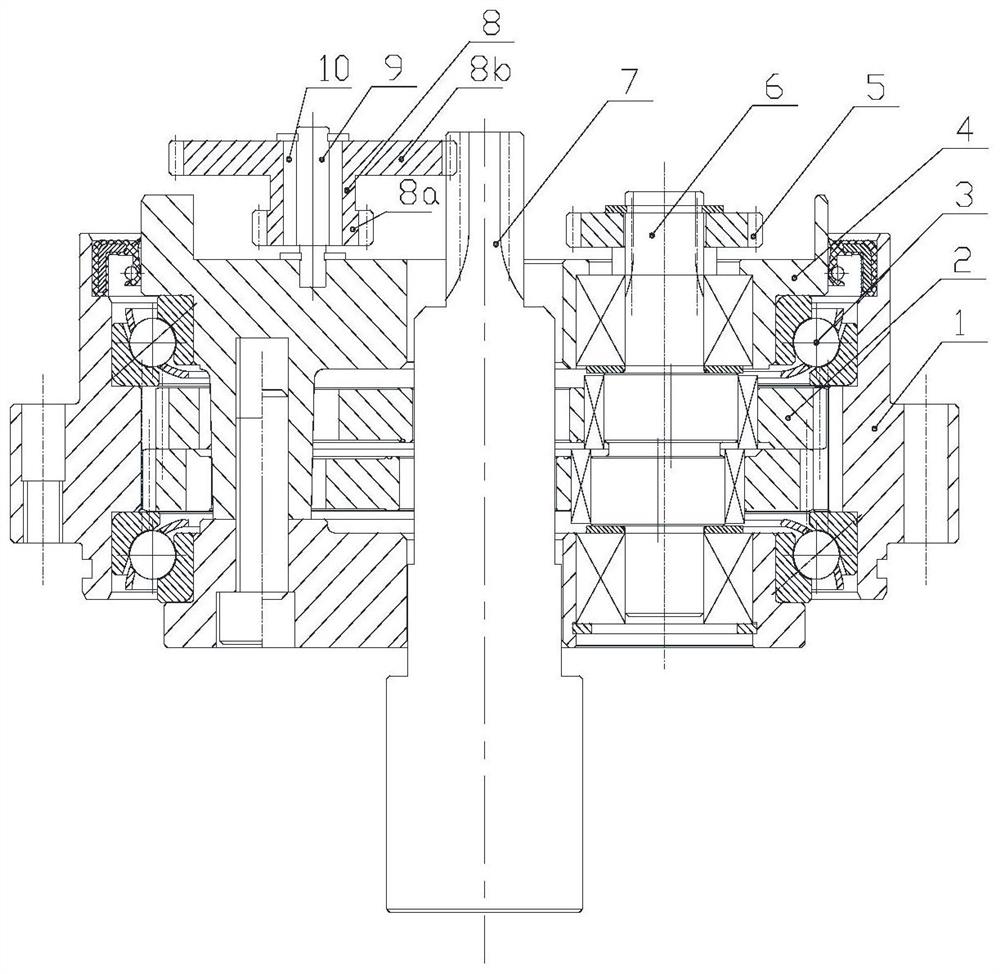

[0031] Such as Figure 3-Figure 5 As shown, a RV reducer with large reduction ratio, the RV reducer includes: pin gear housing 1, cycloid wheel 2, angular contact ball bearing 3, output frame 4, planetary gear 5, eccentric shaft 6, input shaft 7. Adjusting gear 8; the input shaft 7 is located at the center of the RV reducer, and the end of the input shaft 7 has a gear structure with a diameter smaller than or equal to the diameter of the end of the input shaft 7; the planetary gear 5 and the eccentric shaft 6 are at least two groups and surround the input The shaft 7 is symmetrically distributed; the planetary gear 5 is located at one end of the eccentric shaft 6; the planetary gear 5 is not in direct contact with the gear structure at the end of the input shaft 7, and is meshed and connected through at least two sets of adjustment gears 8; the cycloidal gear 2 The bearing is fitted outside the cam 6a of the eccentric shaft 6; the output disc frame 4 is fitted outside the ecce...

Embodiment 2

[0037] Such as Figure 3-Figure 5 As shown, a RV reducer with large reduction ratio, the RV reducer includes: pin gear housing 1, cycloid wheel 2, angular contact ball bearing 3, output frame 4, planetary gear 5, eccentric shaft 6, input shaft 7. Adjusting gear 8; the input shaft 7 is located at the center of the RV reducer, and the end of the input shaft 7 has a gear structure with a diameter smaller than or equal to the diameter of the end of the input shaft 7; the planetary gear 5 and the eccentric shaft 6 are at least two groups and surround the input The shaft 7 is symmetrically distributed; the planetary gear 5 is located at one end of the eccentric shaft 6; the planetary gear 5 is not in direct contact with the gear structure at the end of the input shaft 7, and is meshed and connected through at least two sets of adjustment gears 8; the cycloidal gear 2 The bearing is fitted outside the cam 6a of the eccentric shaft 6; the output disc frame 4 is fitted outside the ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com