Rice drying equipment

A technology for drying equipment and rice, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of long time consumption, pollution, uneven water removal, etc., and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is further described in detail through specific implementation methods:

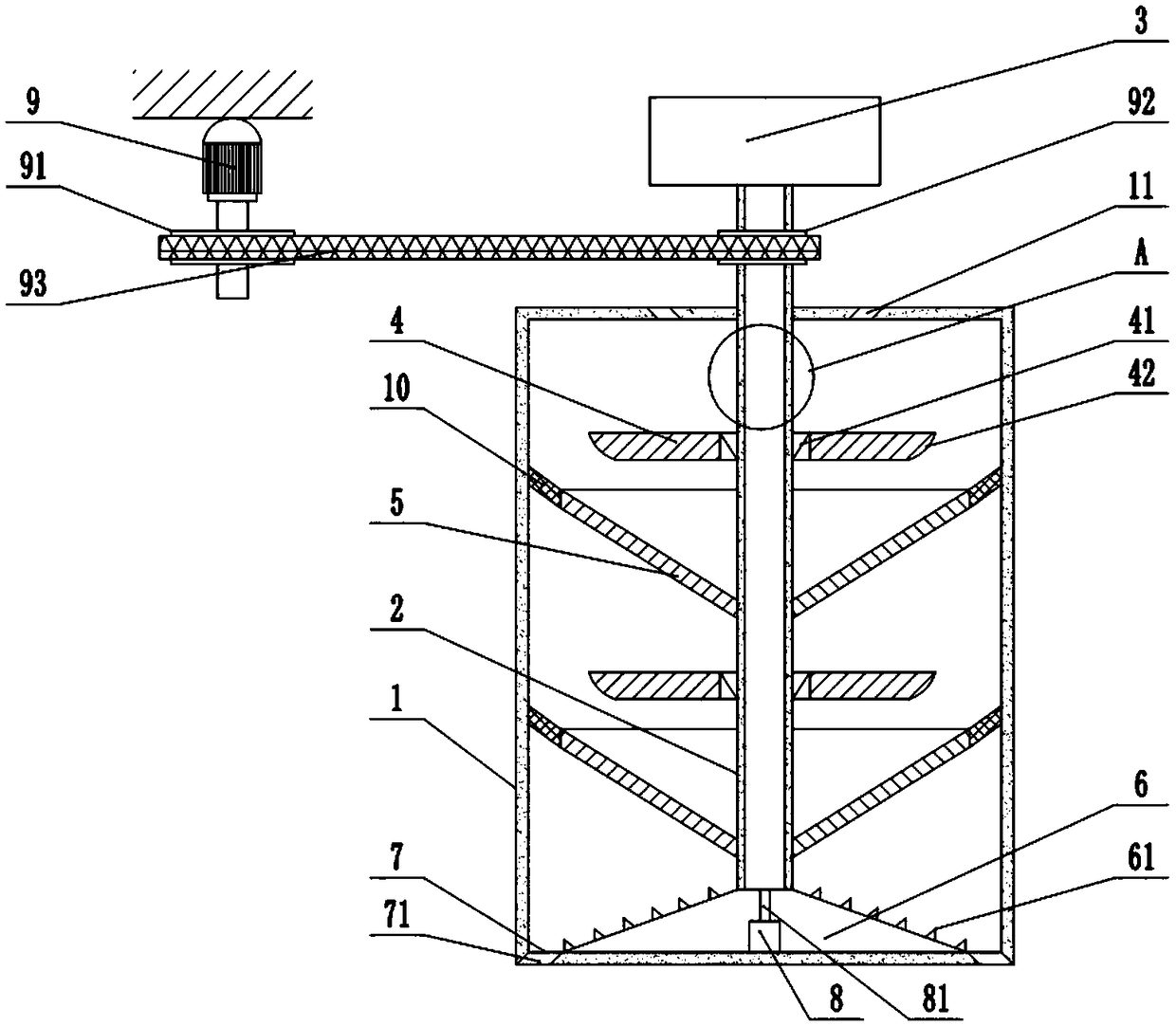

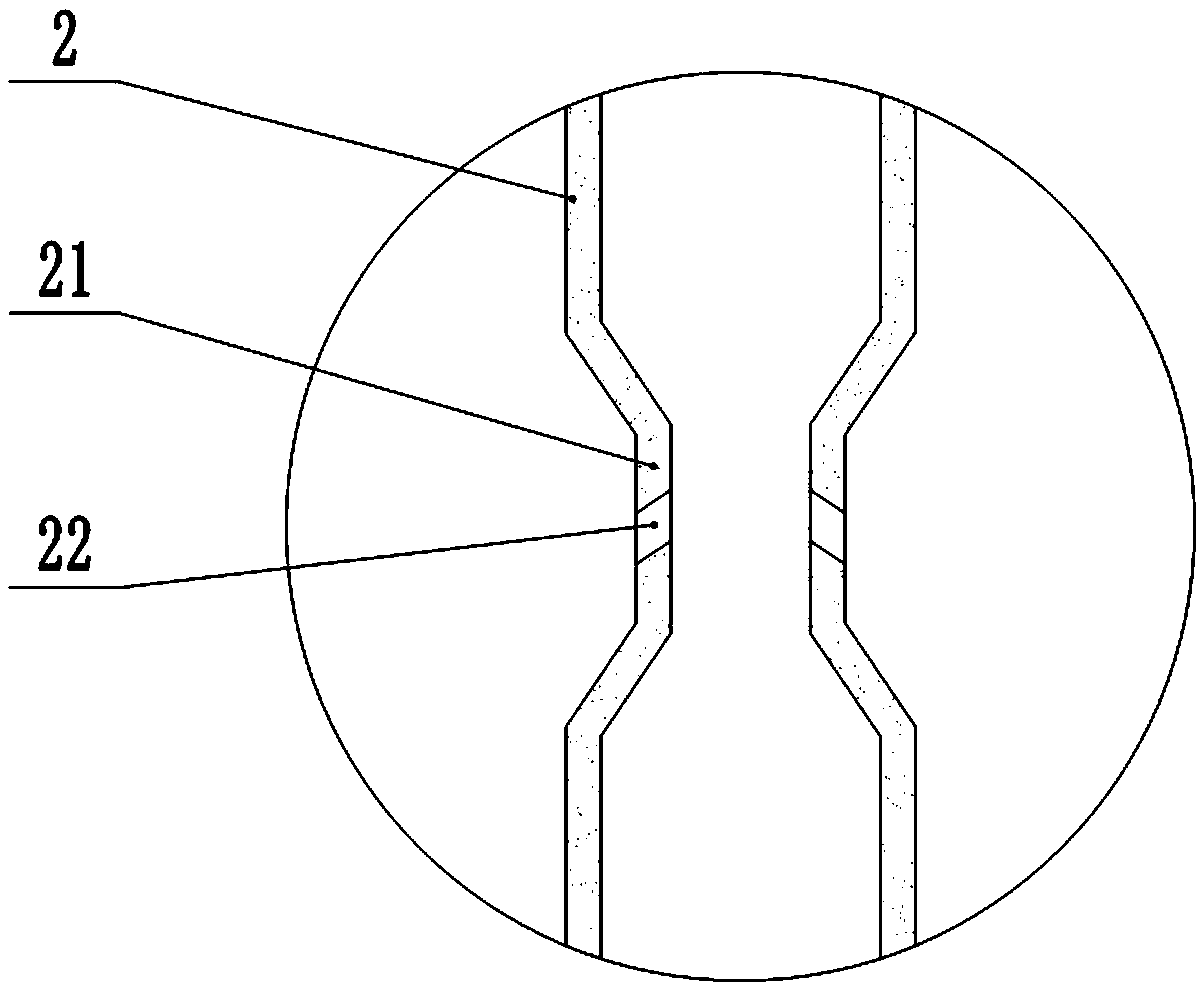

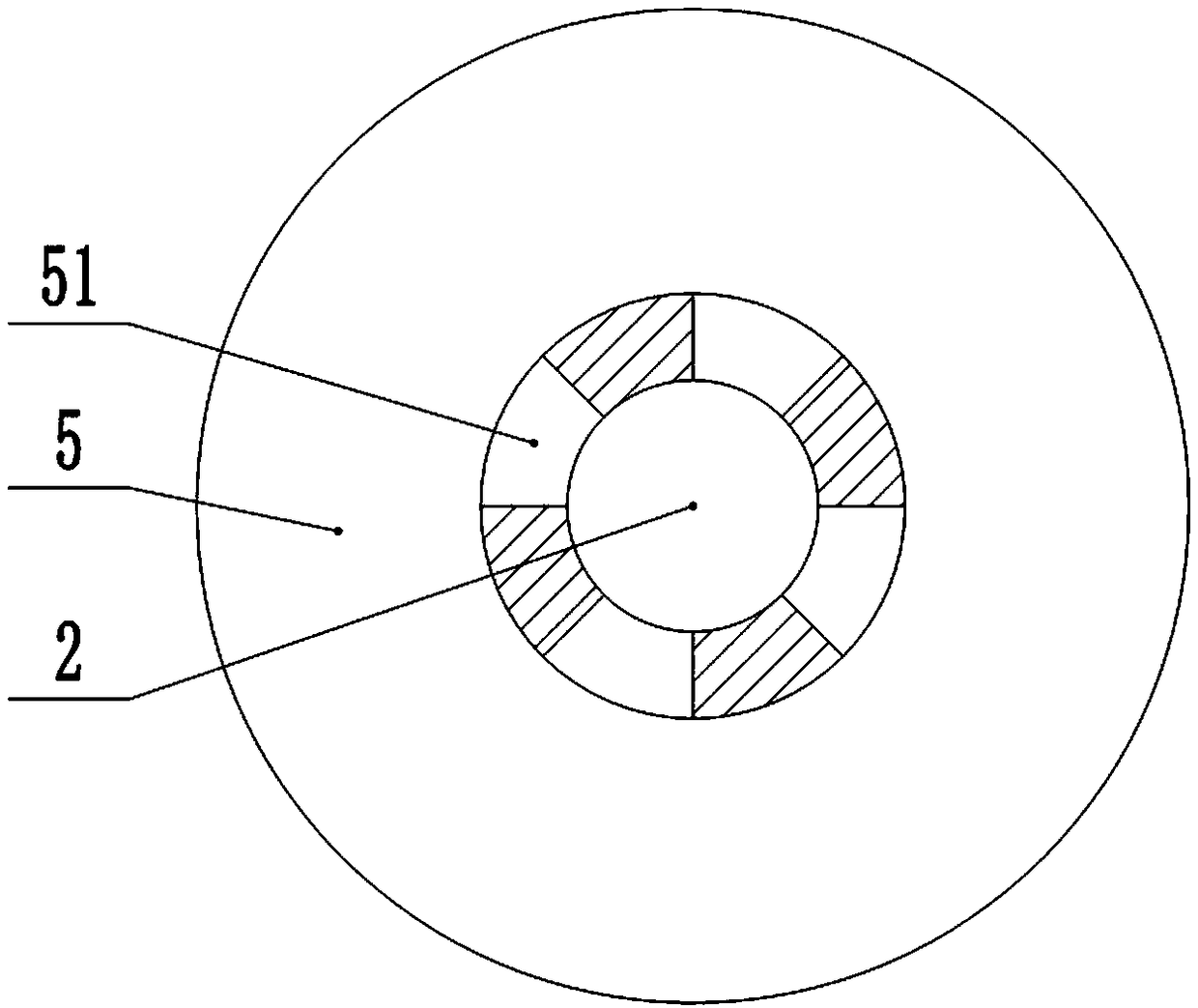

[0023] The reference signs in the drawings of the description include: housing 1, feed inlet 11, rotating shaft 2, second section 21, opening 22, gas collection box 3, turntable 4, one-way bearing 41, edge 42, funnel 5, Notch 51, truncated cone 6, protrusion 61, groove 7, discharge port 71, hot air blower 8, conduit 81, motor 9, driving wheel 91, driven wheel 92, belt 93, screen cloth 10.

[0024] The embodiment is basically as attached figure 1 Shown:

[0025] The rice drying equipment includes a motor 9, a housing 1, a turntable 4 and a vertically arranged rotating shaft 2. The rotating shaft 2 is driven by a transmission mechanism. The transmission mechanism includes a drive wheel 91 arranged on the output shaft of the motor 9. The driving wheel 92, and the belt 93 sheathed between the driving wheel 91 and the driven wheel 92, the top surface of the housing 1 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com