Test system and method for determination of visible light light-cured resin full-field strain

A technology of light-curing resin and testing method, which is applied in measurement devices, optical devices, instruments, etc., can solve the problems of difficulty in measuring the movement of particles, failure to realize real-time image acquisition, difficulty in experimental operation, etc., and achieve accurate non-contact measurement. , to improve the effect of overexposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

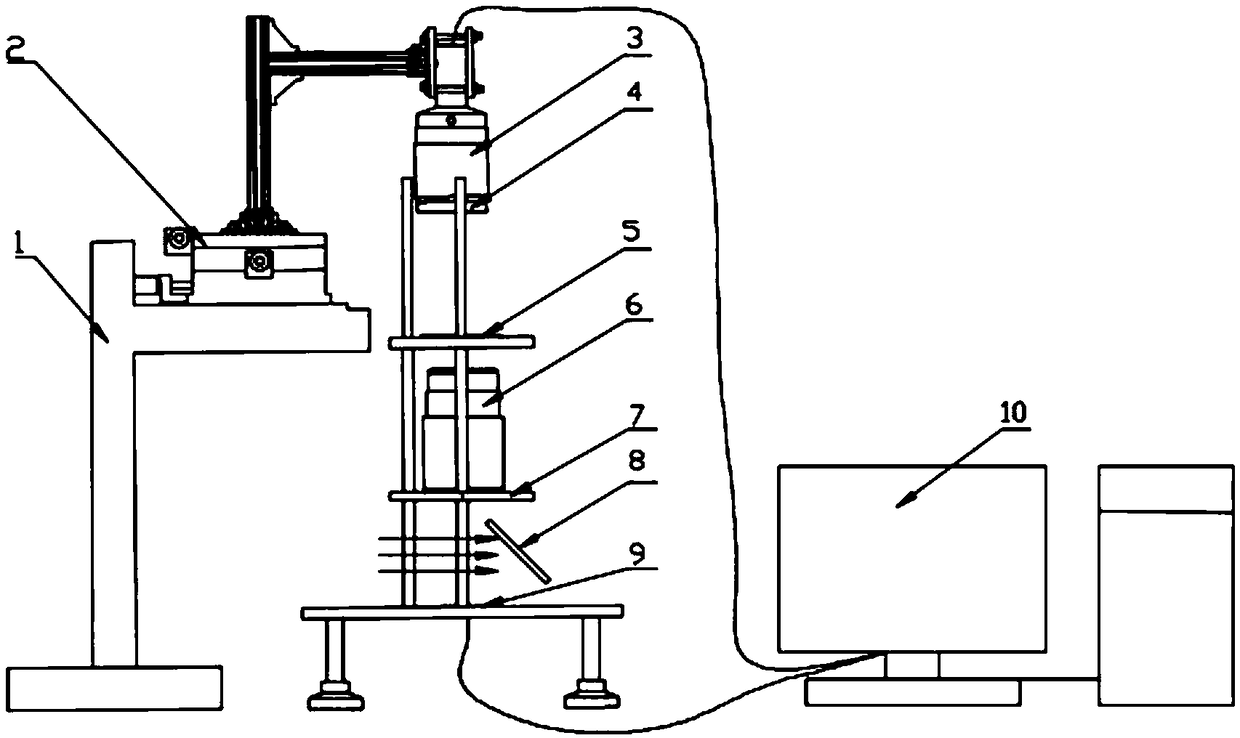

[0026] A test system for determining the full-field strain of a visible-light photocurable resin includes an image generation module, an image acquisition module, and an image analysis module.

[0027] The image generation module includes visible light, a bracket, and a digital micromirror chip (DMD: Digital Micromirror Device) mounted on the bracket in sequence from bottom to top, a flat mirror, a focusing lens, and a resin glass slide. The plane reflector is set at 45°, and the visible light is horizontally irradiated to the plane reflector, and is vertically reflected downward to the digital micromirror chip after passing through the plane reflector.

[0028] The image acquisition module includes a support frame, an adjustable attenuation mirror, an industrial camera clamping device installed on the support frame and an industrial camera clamped on the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com