Auxiliary test tool and method for wave spring

A technology of wave springs and testing methods, which is applied in wave spring auxiliary test tooling and testing fields, can solve the problem of low precision, inability to accurately reflect the elastic force-deformation relationship of wave springs, and the inability to accurately and completely reflect the actual elastic force-deformation relationship of wave springs and other problems, to avoid mechanical clearance, improve accuracy and test efficiency, and facilitate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

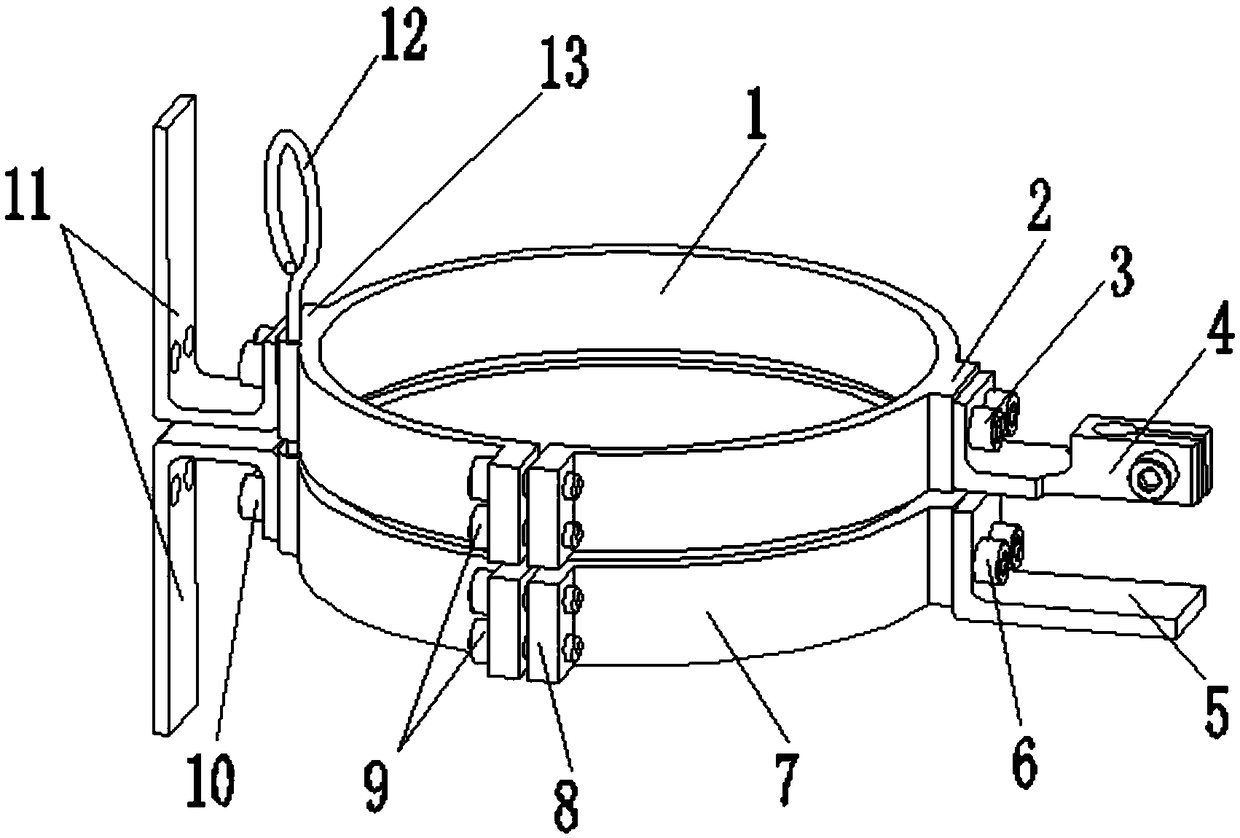

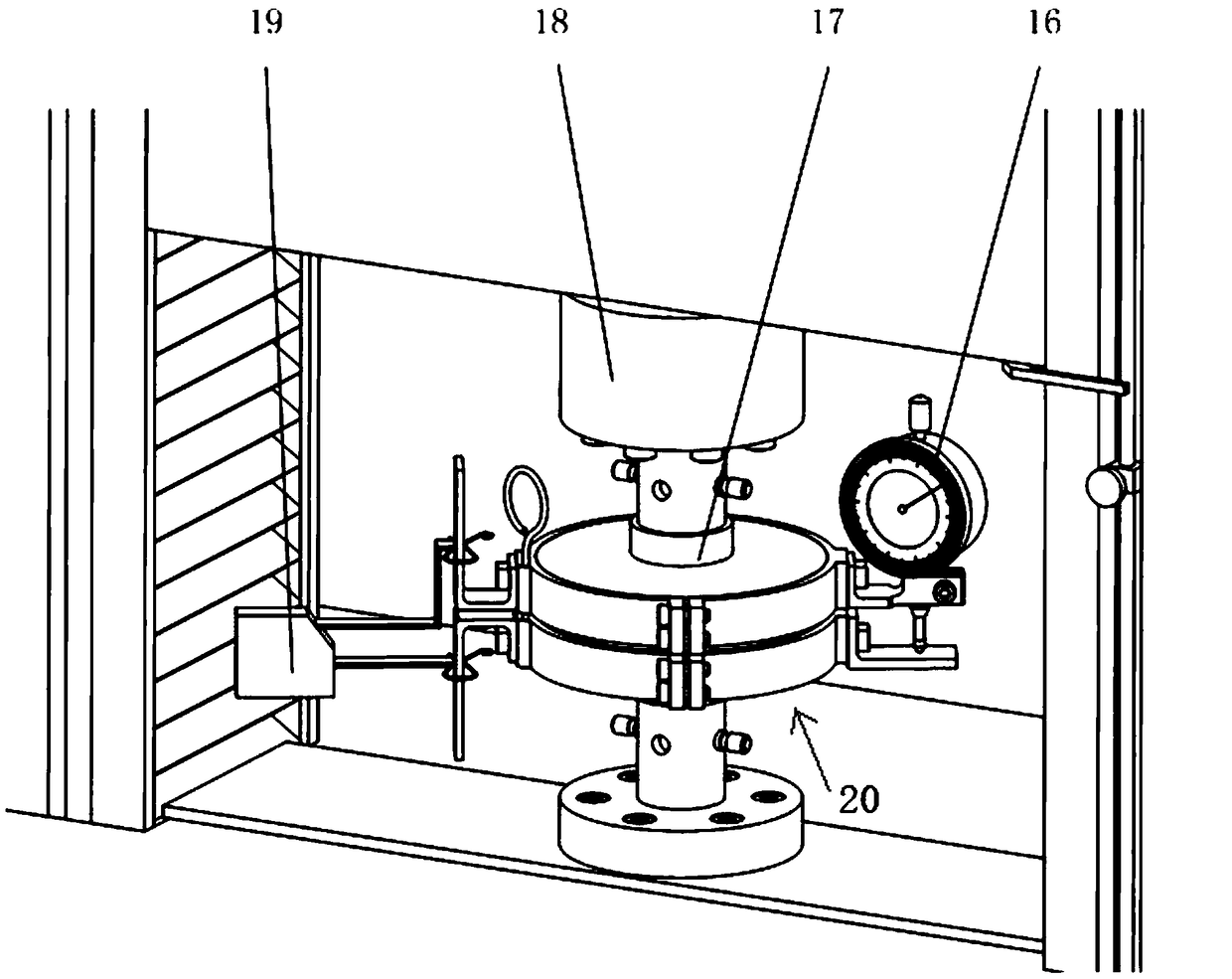

[0032] Such as figure 1 , figure 2 As shown, a wave spring auxiliary test fixture, including

[0033] The upper hoop 1 and the lower hoop 7, the inner diameter of the upper and lower hoops is compatible with the outer diameter of the pressure plate of the electronic universal material testing machine, and the upper hoop 1 is used to hug the upper pressure plate 17 of the electronic universal material testing machine The upper and lower hoops 7 are used to hug the lower pressure plate 20 of the electronic universal material testing machine; the two ends of the upper hoop 1 are provided with lugs 8, and the two lugs 8 are connected by fixing screws 9, so that The upper hoop 1 is hugged tightly on the upper pressure plate 17, and the two ends of the lower hoop 7 are provided with lugs 8, and the two lugs 8 are connected by fixing screws 9, so that the lower hoop 7 is tightly hugged on the lower pressure plate 20 superior;

[0034] The extensometer 19 is installed on the upper...

Embodiment 2

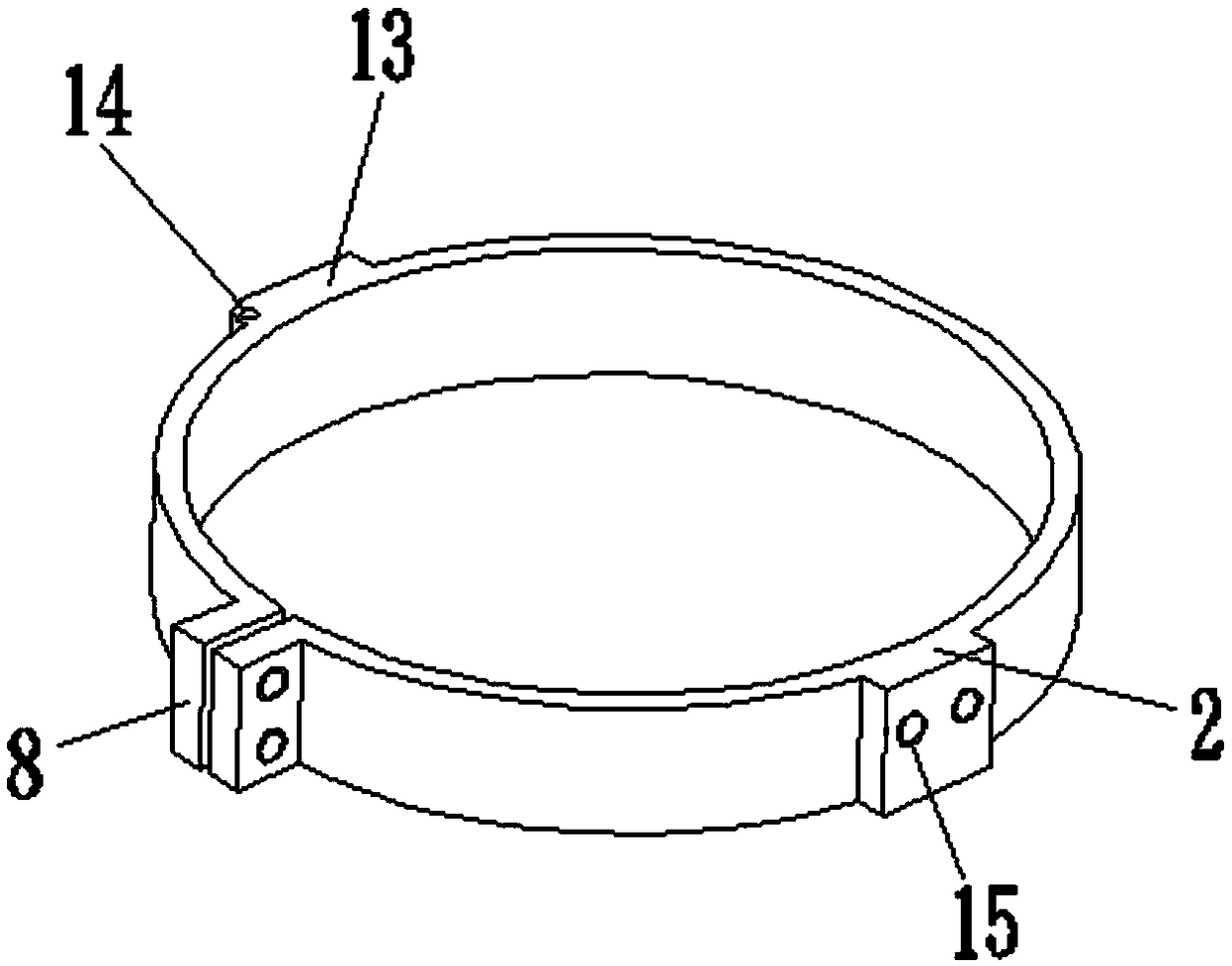

[0048] Such as figure 2 As shown, a wave spring auxiliary test fixture, including

[0049] The upper hoop 1 and the lower hoop 7, the inner diameter of the upper and lower hoops is compatible with the outer diameter of the pressure plate of the electronic universal material testing machine, and the upper hoop 1 is used to hug the upper pressure plate 17 of the electronic universal material testing machine The upper and lower hoops 7 are used to hug the lower pressure plate 20 of the electronic universal material testing machine; the two ends of the upper hoop 1 are provided with lugs 8, and the two lugs 8 are connected by bolts, so that the upper hoop The ring 1 is hugged tightly on the upper pressure plate 17, and the two ends of the lower hoop 7 are provided with lugs 8, and the two lugs 8 are connected by bolts, so that the lower hoop 7 is tightly hugged on the lower pressure plate 20;

[0050] The extensometer 19 is installed on the upper hoop 1 and the lower hoop 7, and...

Embodiment 3

[0052] The upper hoop 1 and the lower hoop 7, the inner diameter of the upper and lower hoops is compatible with the outer diameter of the pressure plate of the electronic universal material testing machine, and the upper hoop 1 is used to hug the upper pressure plate 17 of the electronic universal material testing machine The upper and lower hoops 7 are used to be hugged on the lower platen 20 of the electronic universal material testing machine;

[0053] The extensometer 19 is installed on the upper hoop 1 and the lower hoop 7, and is used to measure the change of the distance between the upper and lower hoops. An extensometer support 11 is respectively installed on the upper hoop 1 and the lower hoop 7, and the extensometer 19 is installed on the two extensometer supports 11. When installing, it is necessary to ensure that the upper and lower positions of the two extensometer supports are consistent. This situation is not shown in the figure.

[0054] The wave spring auxil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com