Method for rapidly testing content of lead element in plated layer of tin plate

A technology for rapid determination and element content, applied in the detection field, can solve the problems of low detection accuracy, large matrix interference, and long detection time, and achieve the effects of high atomic absorption sensitivity, short detection time and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In order to better understand the above technical solution, the above technical solution will be described in detail below in conjunction with specific implementation manners.

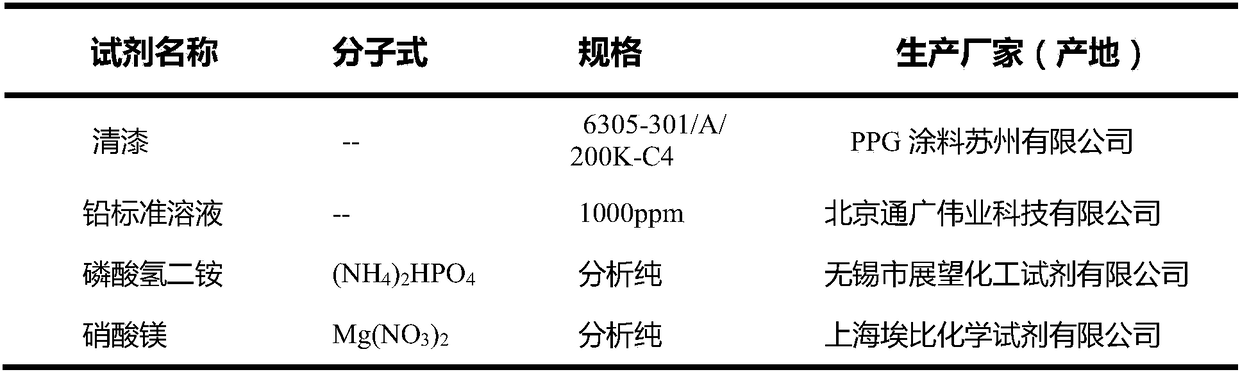

[0029] The reagents and raw materials used in the present invention are as shown in Table 1 below:

[0030] Table 1 Reagents and raw materials used in the present invention

[0031]

[0032] instrument :

[0033] ·Electrolytic tin removal equipment: electrochemical workstation, Shanghai Chenhua Instrument CHI760E

[0034] Setting of experimental conditions: choose chronopotentiometry, and set the parameters as Catholic Current 0.005A, Anodic Current 0.24A, Catholic Time 0.005s, Anodic Time 300s, Initial PolarityAnodic.

[0035] · Instruments for measuring lead: graphite furnace atomic absorption spectrometer, THERMO FISHER SCIENTIFIC, ICE3300

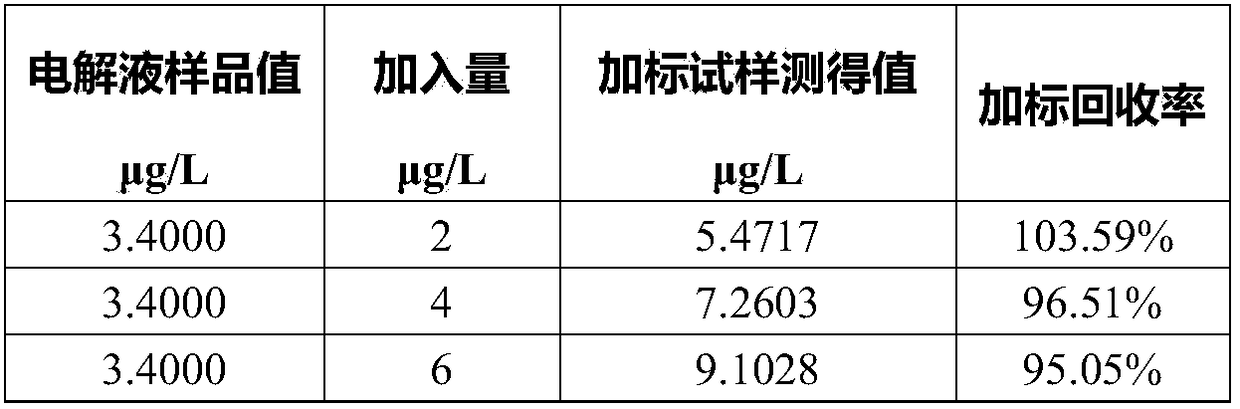

[0036] Experimental condition settings: wavelength 217nm, lamp current 10A, spectral passband width 0.5nm, sample injection volume 15μL, diammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com