On-line monitor for partial discharge fault of dry type air reactor based on high-frequency signal

An air-core reactor and partial discharge technology, which is applied in the direction of instruments, measuring electronics, and measuring devices, can solve problems such as temperature rise, low real-time performance, and delay characteristics, and achieve reliable response, good real-time performance, and fast response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

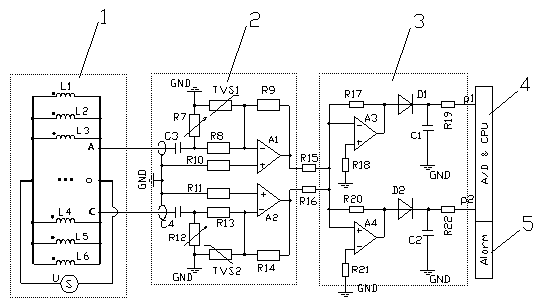

[0028] Example: see figure 1 , figure 2 , a dry-type air-core reactor partial discharge fault online monitor based on high-frequency signals, including a fault signal detection unit 1 , a preamplifier unit 2 , a peak hold unit 3 and a data acquisition and processing unit 4 .

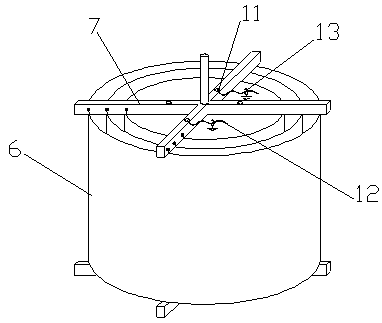

[0029] The fault signal detection unit 1 includes two fault signal monitoring terminals 11, the two fault signal monitoring terminals 11 are respectively connected to a coaxial cable 12, and a shielding ring 13 is respectively sleeved on the two coaxial cables 12, and the shielding ring 13 is grounded . During use, connect the two fault signal monitoring terminals 11 to the corresponding positions of the dry-type air-core reactor 6 located on the two diagonal busbars 7; in this way, when a fault occurs, the high-frequency signal will flow into one of the busbars, Then "shunt" to several other busbars, resulting in a large difference in the high-frequency signal strength of the two diagonal busbars, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com