Prefabricated optical cable connector and welding-free optical fiber distribution case

A technology of optical fiber distribution box and prefabricated optical cable, which is applied in the coupling of optical waveguide and fiber mechanical structure, etc. It can solve the problems of difficulty in guaranteeing the quality of fusion splicing at the construction site, high repair rate of repeated fusion splicing, and heavy workload of on-site fusion splicing, etc., and achieves convenience The effects of post-operation management and maintenance, improvement of project construction quality, and shortened on-site construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

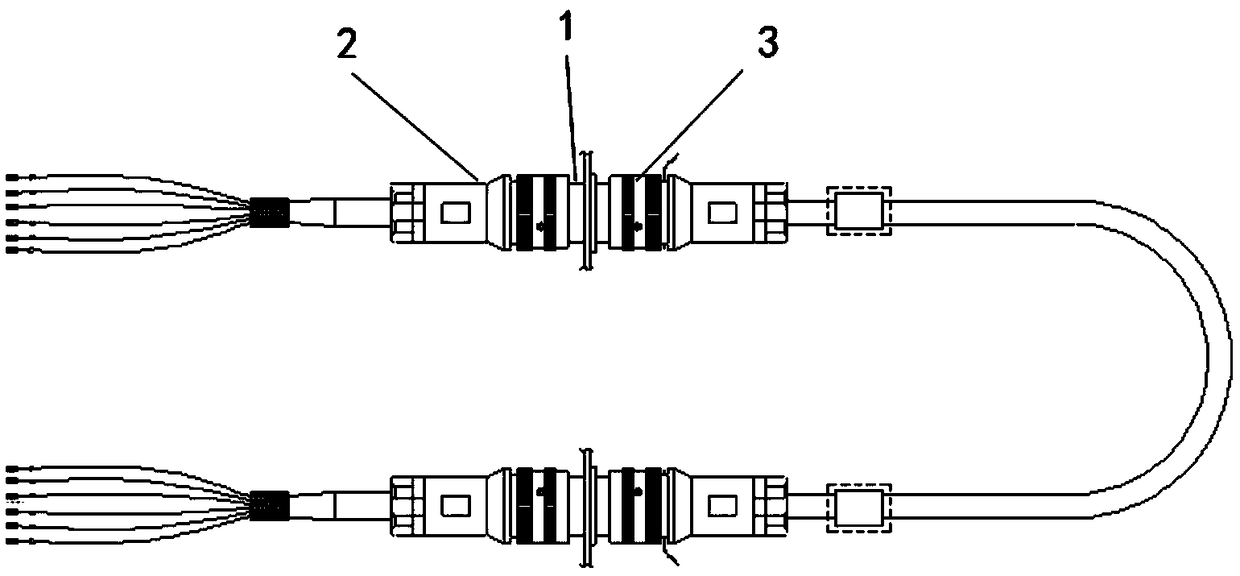

[0029] Such as figure 1 As shown, the prefabricated optical cable connector provided by the present invention includes a prefabricated optical cable adapter 1 , a prefabricated optical cable plug 2 and a prefabricated optical cable socket 3 .

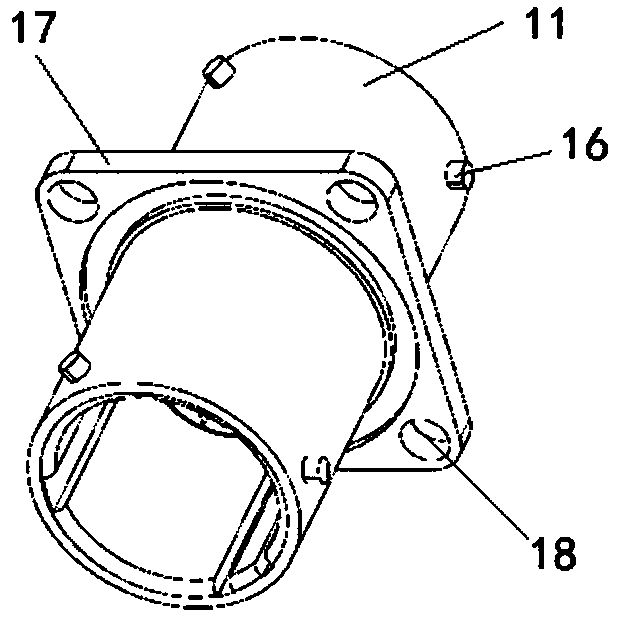

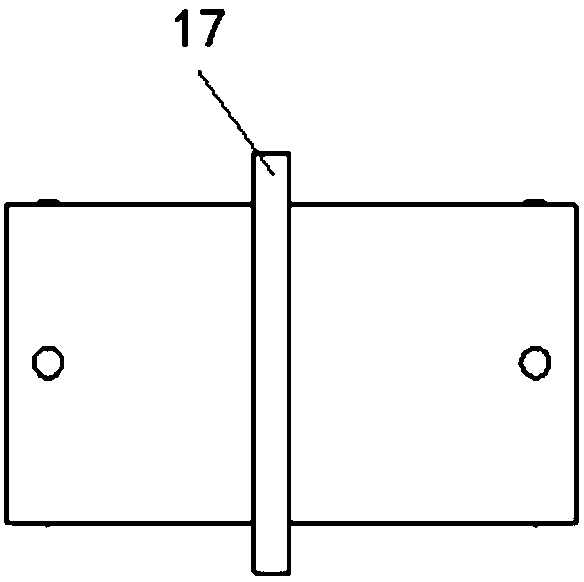

[0030] Such as Figure 2-4 As shown, the prefabricated optical cable adapter 1 includes a cylindrical base 11 with openings at both ends. A radial main keyway 12 and a number of radial auxiliary keyways 13 are provided at intervals on the inner side of the cylindrical base 11. Each of the auxiliary keyways 13 of the present invention The number is four, and this is taken as an example, not limited thereto. A connecting plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com