Simulation analyzing and modeling method for vertical cracking damage of basin rubber bearing bottom basin

A technology for rubber bearings and simulation analysis, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as uneven installation at the bottom of the bearing, large included angle, cracks and deformation of steel parts, and save energy The effect of post-maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

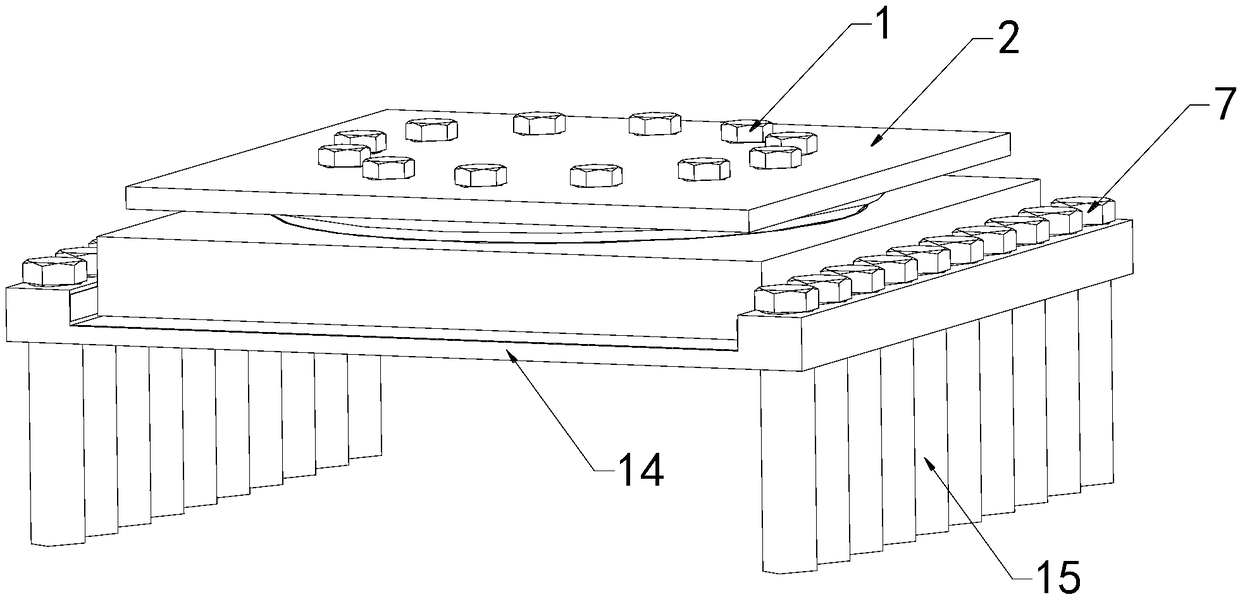

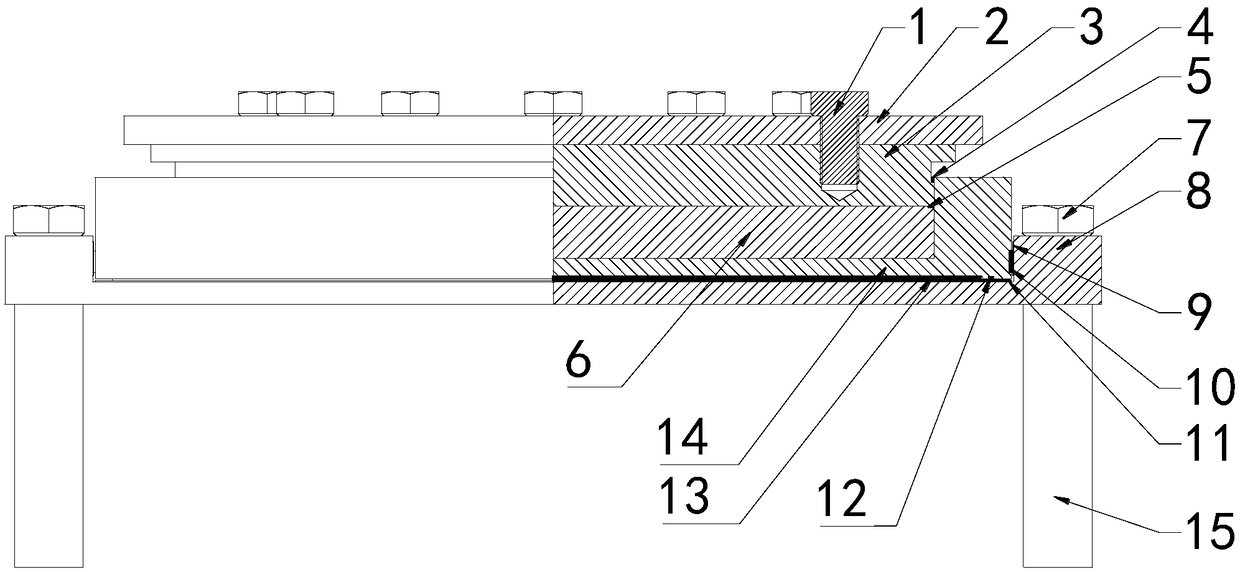

[0041] The following will be figure 1 and figure 2 Taking the vertically movable basin-type rubber bearing as an example, the simulation analysis and modeling method for the vertical cracking and failure of the bottom basin of the basin-type rubber bearing of the present invention will be further described in detail. like figure 1 and figure 2As shown, the vertically movable basin rubber bearing in this embodiment includes an upper anchor bolt 1, an embedded plate 2, a piston 3, a sealing ring 1 4, a tightening ring 5, a rubber pad 6, a lower anchor bolt 7, and a guide rail 8. Side stainless steel strip 9, SF-1 wear-resistant strip 10, flat stainless steel plate 11, sealing ring II12, grinding plate 13 (generally PTFE wear-resistant plate), bottom basin 14, lower anchorage steel rod 15. The assembly relationship is detailed in figure 1 and figure 2 .

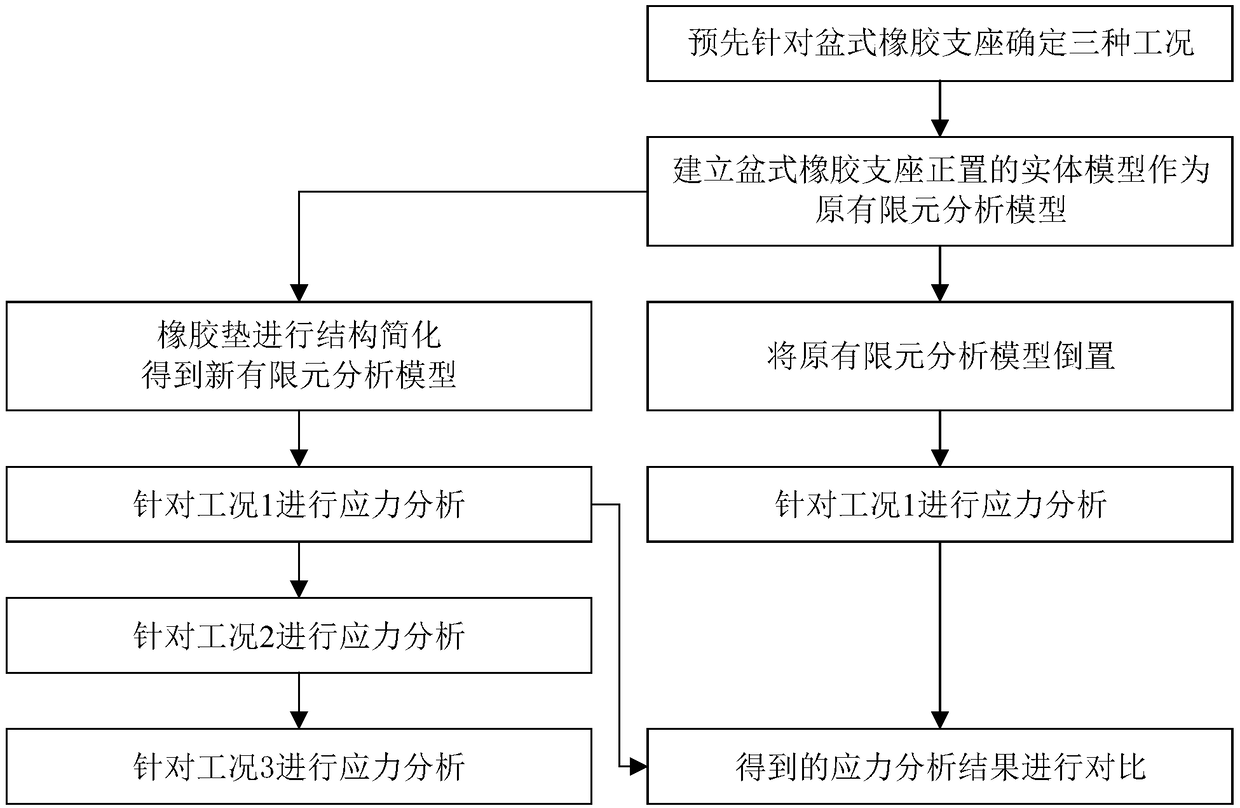

[0042] like image 3 As shown, the implementation steps of the vertical cracking failure simulation analysis and mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com