Windproof dust inhibiting net

A technology of windproof and dust suppression net and windproof net, which is applied in the direction of protective equipment, fences, building types, etc., to achieve good windproof effect, anti-corrosion measures, low post-maintenance costs, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

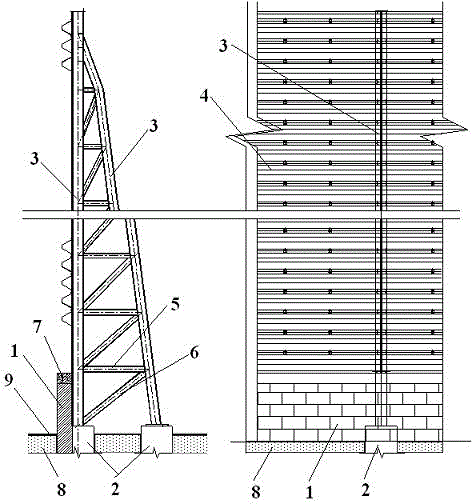

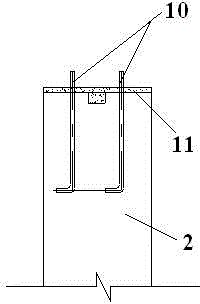

[0015] like figure 1 and 2 As shown, a windproof and dust-suppressing net adopts a net-wall structure as a whole, including a sill wall 1, a cap pile 2, a steel bracket 3 and a windproof mesh 4, and the sill wall 1 is made of clay bricks with a thickness of On the 0.5m C40 fine stone reinforced concrete cushion 8, several cap piles 2 are arranged on the back of the sill wall 1. The cap piles 2 are C30 reinforced concrete structures, and the top layer is laid with a C40 fine stone concrete filling layer 11 The height of the sill wall 1 is 2.5 times the height of the cap pile 2, and the steel support 3 is fixedly installed on the cap pile 2 by using a pre-embedded M36 anchor bolt 10 (the anchor bolt exposes the structural column top 200mm); The sill wall 1 is in the form of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com