Method for preparing oxide thin film transistor by solution method

A technology for oxide thin films and transistors, which is applied in the manufacture of transistors, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of difficult production, fixed components, and high process costs, and achieve the effects of low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

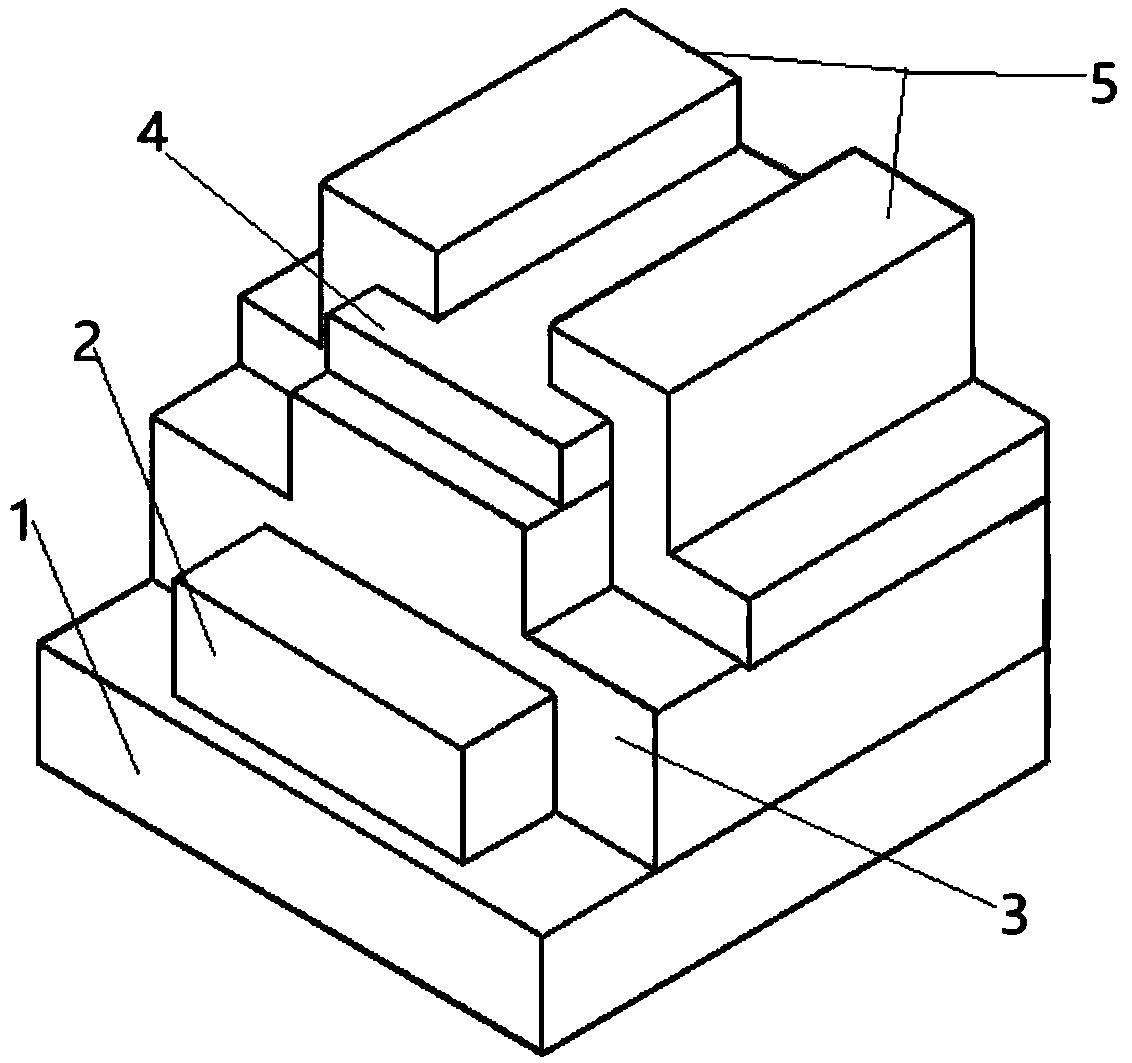

[0028] An oxide thin film transistor of this embodiment is prepared by the following method:

[0029] (1) Precursor preparation: 2.576g Zr(NO 3 ) 4 ·5H 2 O (zirconium nitrate pentahydrate) was dissolved in 10ml ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.6mol / L insulating layer precursor solution; 0.30083g In(NO 3 ) 3 (indium nitrate) was dissolved in 10ml ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.1mol / L active layer precursor solution.

[0030] (2) Substrate preparation: deposit a layer of 150nm ITO electrode on the surface of the glass substrate, wash and dry to obtain the ITO glass substrate.

[0031] (3) Spin-coat the insulating layer precursor solution obtained in step (1) on the ITO glass substrate according to the selected process parameters, the spin-coating speed is 6000rpm, the coating time is 40s each time, and the number of coating times is 3 times. The intermediate annealing temperature is 300° C. fo...

Embodiment 2

[0037] An oxide thin film transistor of this embodiment is prepared by the following method:

[0038] (1) Precursor preparation: 1.288g Zr(NO 3 ) 4 ·5H 2 O (zirconium nitrate pentahydrate) was dissolved in 10ml ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.3mol / L insulating layer precursor solution; 0.90249g In(NO 3 ) 3 (indium nitrate) was dissolved in 10ml ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.3mol / L active layer precursor solution.

[0039] (2) Substrate preparation: deposit a layer of 150nm ITO electrode on the surface of the glass substrate, wash and dry to obtain the ITO glass substrate.

[0040] (3) Spin-coat the insulating layer precursor solution obtained in step (1) on the ITO glass substrate according to the selected process parameters, the spin-coating speed is 4000rpm, the coating time is 30s each time, and the coating times are 6 times. The intermediate annealing temperature is 300° C. for 5 minut...

Embodiment 3

[0045] An oxide thin film transistor of this embodiment is prepared by the following method:

[0046] (1) Precursor preparation: 2.147g Zr(NO 3 ) 4 ·5H 2O (zirconium nitrate pentahydrate) was dissolved in 10ml ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.5mol / L insulating layer precursor solution; 0.60166g In(NO 3 ) 3 (indium nitrate) was dissolved in 10 ml of ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.2 mol / L active layer precursor solution.

[0047] (2) Substrate preparation: deposit a layer of 150nm ITO electrode on the surface of the glass substrate, wash and dry to obtain the ITO glass substrate.

[0048] (3) Spin-coat the insulating layer precursor solution obtained in step (1) on the ITO glass substrate according to the selected process parameters, the spin-coating speed is 5000rpm, the coating time is 30s each time, and the number of coating times is 4 times. The intermediate annealing temperature is 300° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com