Green-yellow light LED epitaxial structure with optimal reflecting layer and preparation method thereof

An epitaxial structure, yellow-green light technology, applied in the field of optoelectronics, can solve the problem of not being proposed, reduce the internal stress of the reflective layer, etc., to achieve the effect of improving light extraction rate, reducing internal stress, and realizing long-term power-on reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

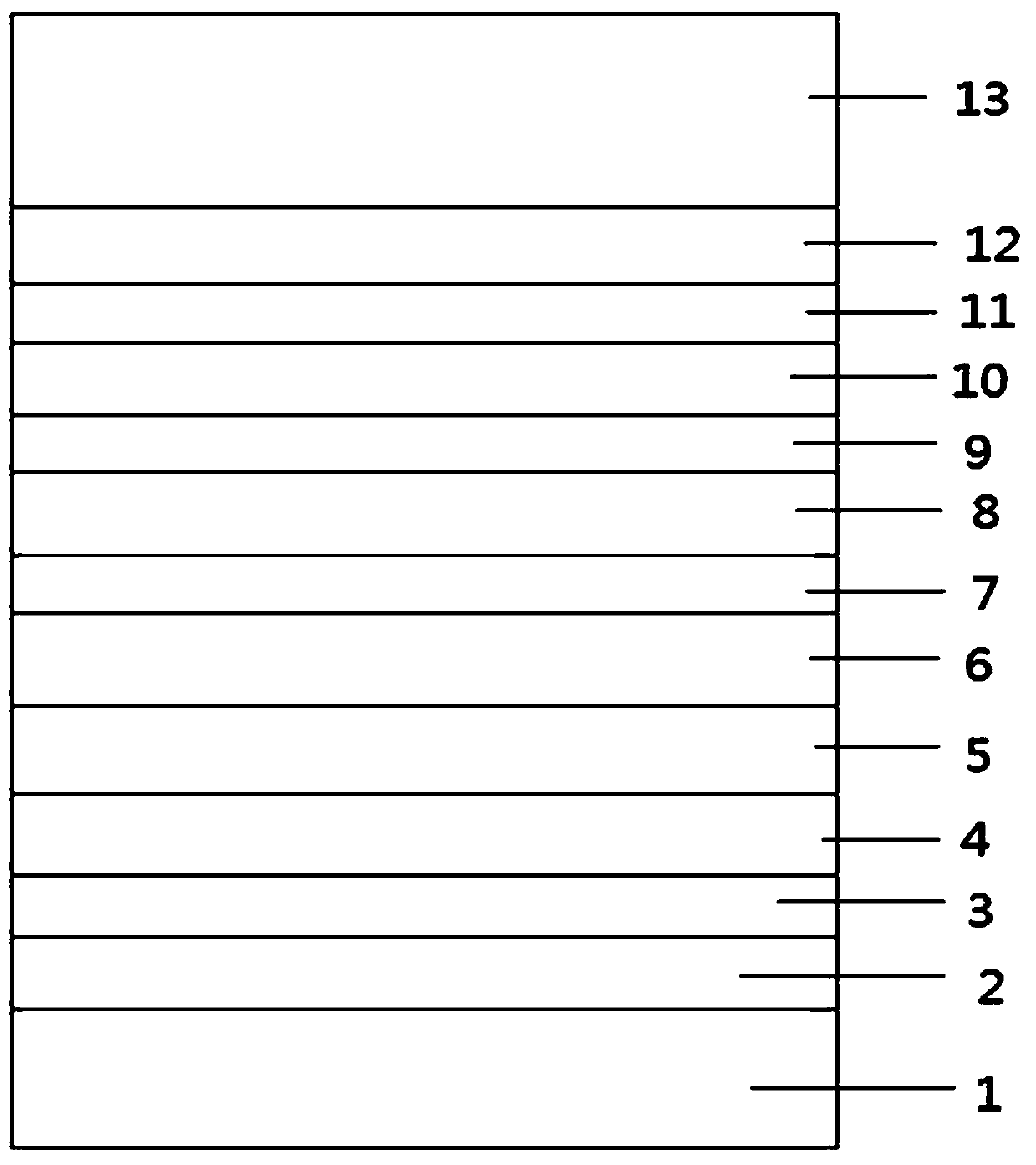

[0032] Preferably, the wavelength of the AlGaAsP / AlAsP DBR layer I4 is 600nm, the wavelength of the AlGaAsP / AlAsP DBR layer II5 is 580nm, and the wavelength of the AlGaAsP / AlAsP DBR layer III6 is 570nm.

[0033] The present invention also relates to a method for preparing a yellow-green LED epitaxial structure with an optimized reflective layer, comprising the following steps:

[0034] a) Put the GaAs substrate 1 into the reaction chamber, and grow a layer of AlnGa1 buffer layer 2 made of AlnGa1-nAs in the temperature range of 300-800 ° C, where the value of n is ≤0.99, and the carrier concentration is 1E17cm -3 -5E18cm -3 ;

[0035] b) Keep the temperature at 300-800°C, turn off the Al source, and turn on the pH 3 , growing a GaAsP buffer layer 3 on the AlnGa1 buffer layer 2;

[0036] c) Adjust the temperature to 700-500°C, and feed the pH 3 , adjust the growth thickness and grow 1-30 pairs of AlAsP / AlGaAsP DBR layer Ⅰ 4 that reflect 600nm spectrum and the material is Alx...

Embodiment 2

[0050] Preferably, the carrier concentration in step b) is 1E18cm -3 -5E18cm -3 , the carrier concentration in step c) is 1E17cm -3 -5E18cm -3 , the carrier concentration in step d) is 1E17cm -3 -5E18cm -3 , the carrier concentration in step e) is 1E17cm -3 -5E18cm -3 , the flow carrier concentration in step f) is 5E17cm -3 -1E18cm -3 , the carrier concentration in step k) is 1E18cm -3 -5E18cm -3 , the carrier concentration in step l) is 1E19cm -3 -9E19cm -3 .

Embodiment 3

[0052] Preferably, pH in step b) 3 Flow rate is 0.1-100cc, pH in step c) 3 The flow rate is 0.1-100cc, and the pH in step d) 3 Flow is 0.1-100cc, PH in step e) 3 The flow rate is 0.1-100cc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com