Mobile phone middle plate laser welding plane welding automatic whole line

A technology of plane welding and radium welding, which is applied in the field of automatic whole line of radium welding plane welding for mobile phone mid-plate, can solve the problems that it is difficult to apply to various types of mid-plate, the degree of automation of the mid-plate is low, and the efficiency is difficult to improve, so as to improve the quality The effect of improving efficiency, improving assembly efficiency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

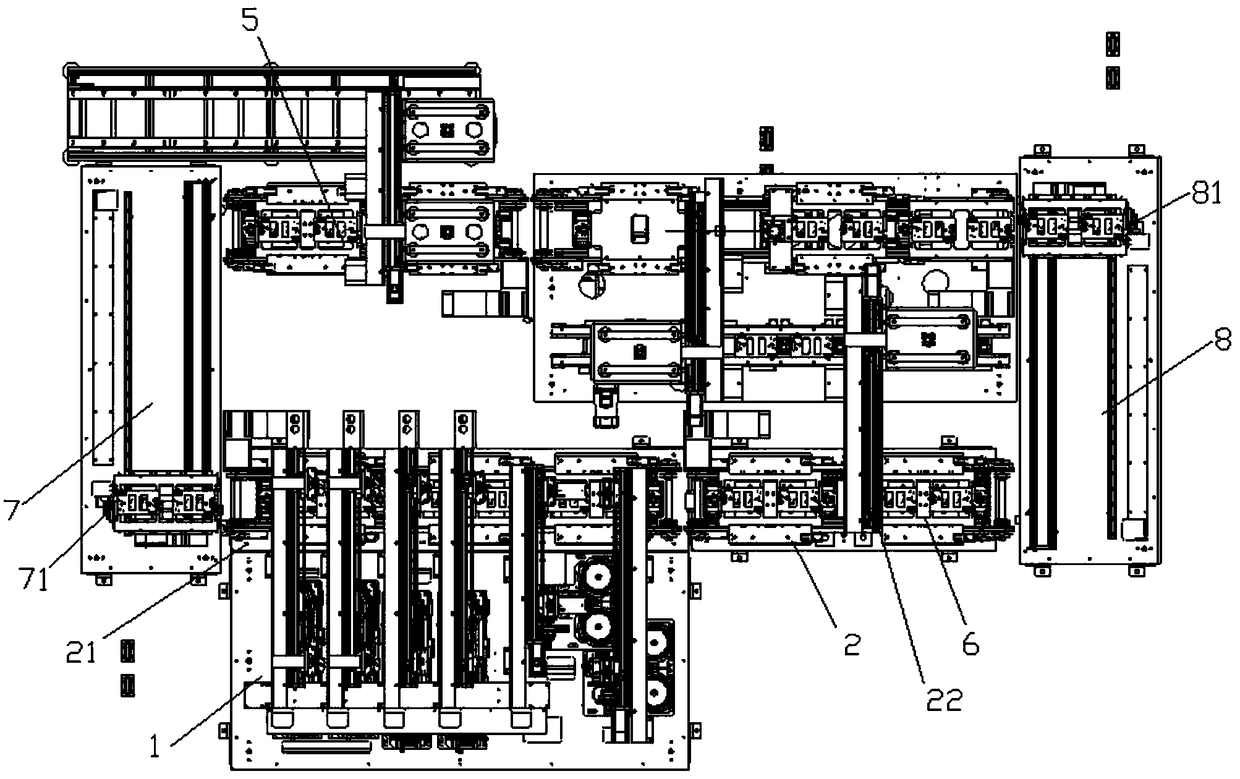

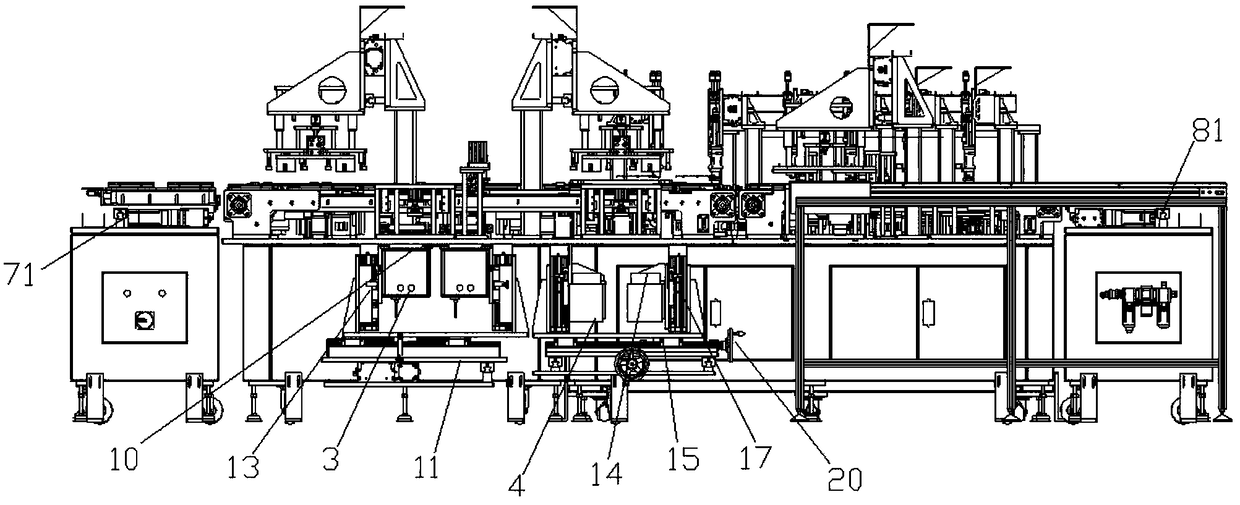

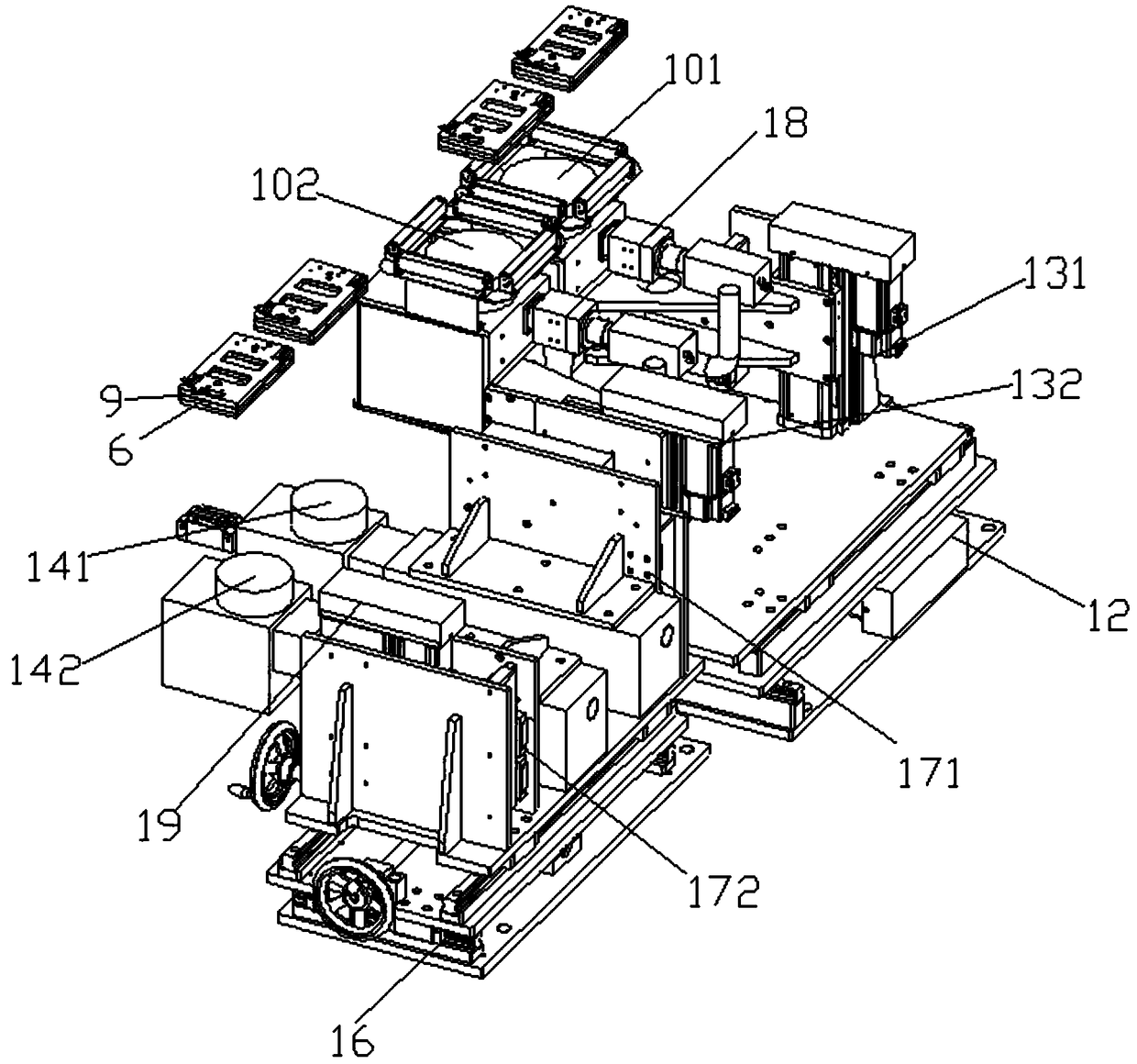

[0022] Such as figure 1 and figure 2 As shown, the automatic complete line of radium welding plane welding for mobile phone mid-plate includes vibrating plate feeding mechanism 1, feeding assembly mechanism 2, radium welding mechanism 3, marking mechanism 4, unloading mechanism 5, and conveying mid-plate The conveying line 21, the conveying line 21 is clamped with the jig 6 for fixing the middle plate, and the cover plate grabbing mechanism for grabbing the upper end of the cover plate fixing jig 6 is arranged above the output end of the feeding assembly mechanism 2 22. The jig 6 is integrally molded with a through hole 9, and the input side of the vibrating plate feeding mechanism 1 is connected to the first material transfer for moving the jig 6 to the side of the conveying line 21 through a bracket stud. Slider 7, the stud at one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com