Highway and railway dual-purpose vehicle

A technology for road-rail dual-purpose vehicles and frames, which is applied to track and road dual-purpose vehicles, motor vehicles, transportation and packaging, etc. It can solve the problems of increasing transit time and limiting the number of railway stations, so as to improve transit time and reduce Threshold, the effect of preventing excessive rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

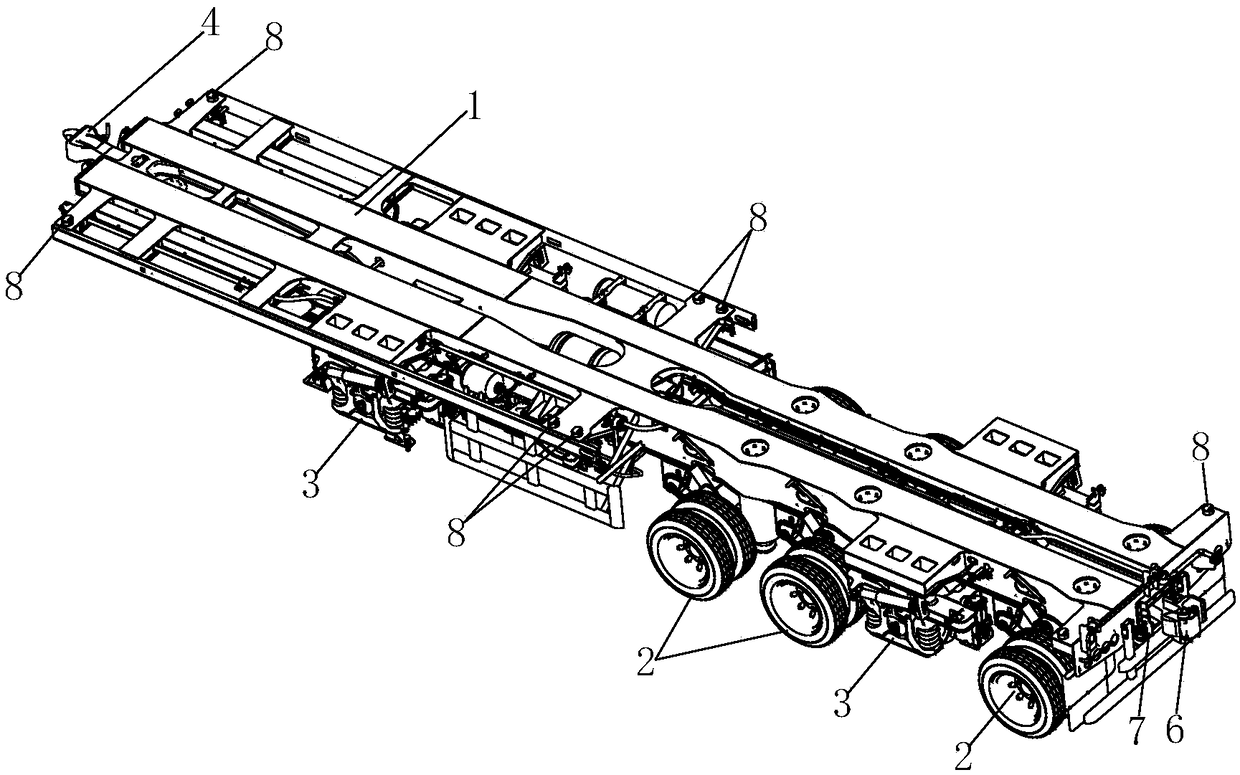

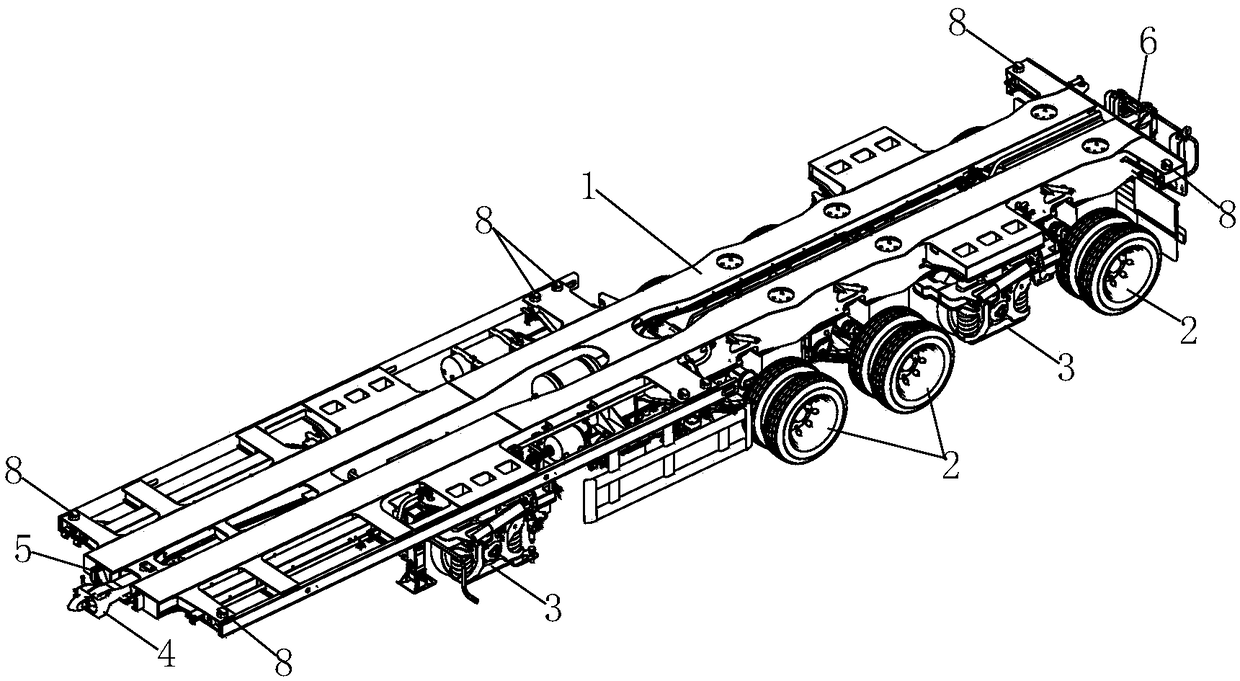

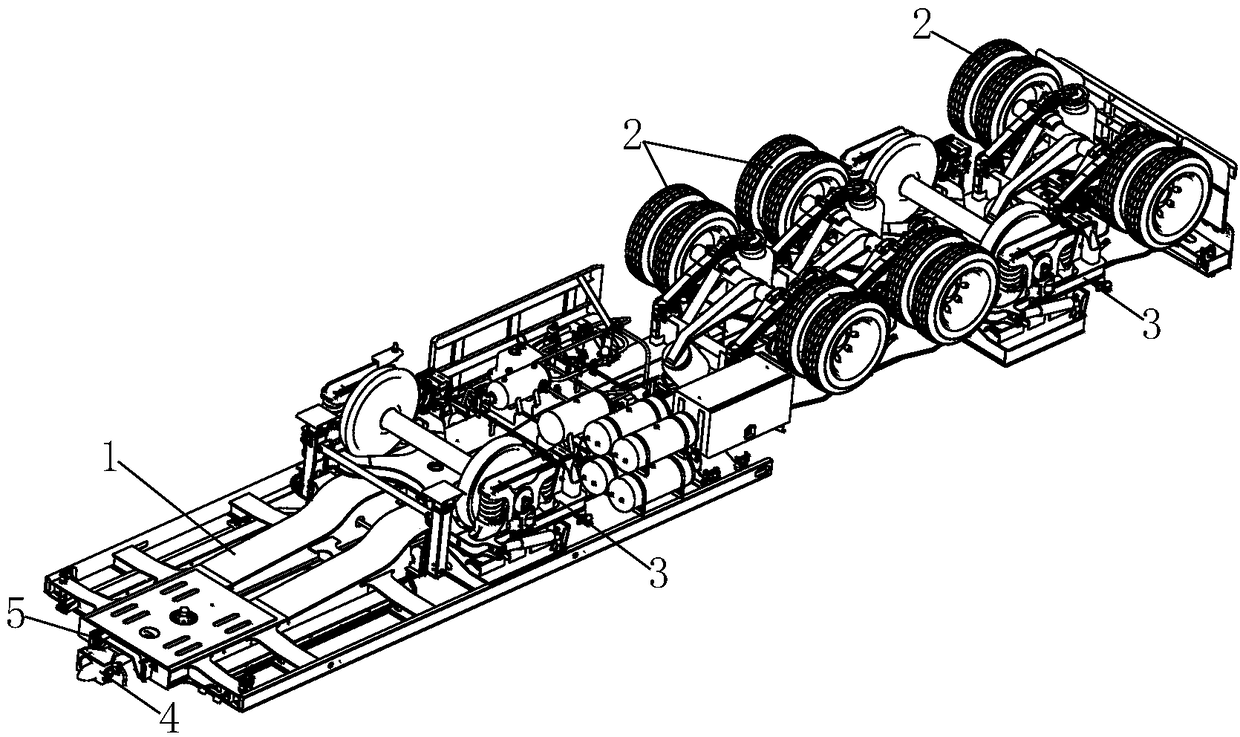

[0103] like Figure 1-35 As shown, this embodiment provides a road-rail vehicle, including a vehicle frame 1, a suspension 2 and a single-axle bogie 3, the vehicle frame 1 includes two longitudinal beams 1a arranged in parallel, and the two longitudinal beams 1a The beams 1a are connected by a longitudinal beam connecting plate 1b, and a lifting airbag mounting seat 1c is provided between the two longitudinal beams 1a, and a position corresponding to the lifting airbag mounting seat 1c is set on the lower cover plate of the longitudinal beam 1a. There is a load-bearing airbag insertion hole, a load-bearing airbag mounting seat 1d is installed in the load-bearing airbag insertion hole, and a load-bearing bolster 1e is installed on the outer side of the longitudinal beam 1a;

[0104] The suspension 2 includes an axle assembly 2a, a lifting airbag 2b is installed in the middle of the front end of the axle assembly 2a, and a primary bearing airbag 2c is respectively installed on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com