A method and device for powering off a battery management system

A technology of a battery management system and an electrical method, which is applied in the field of power-off methods and devices of the battery management system, and can solve problems such as insufficient cooperation between VCU and BMS, potential safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

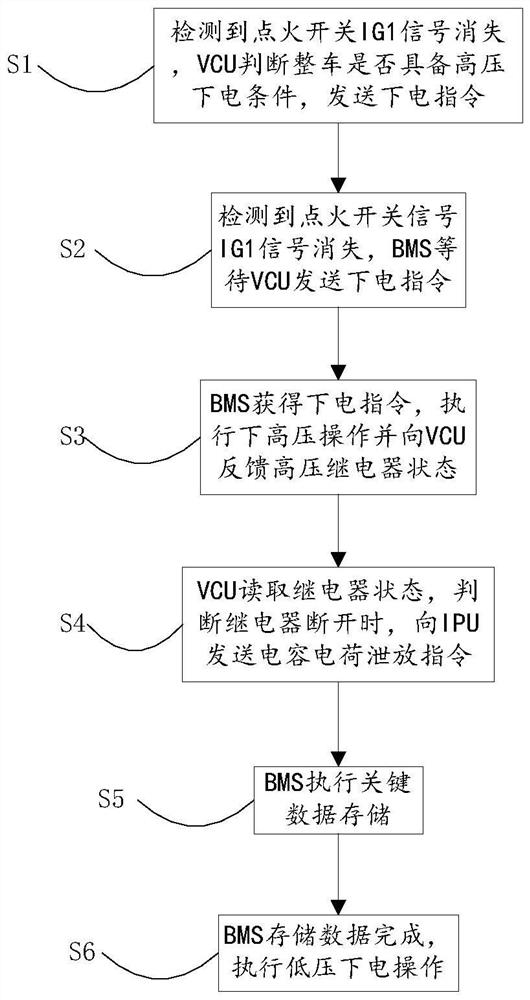

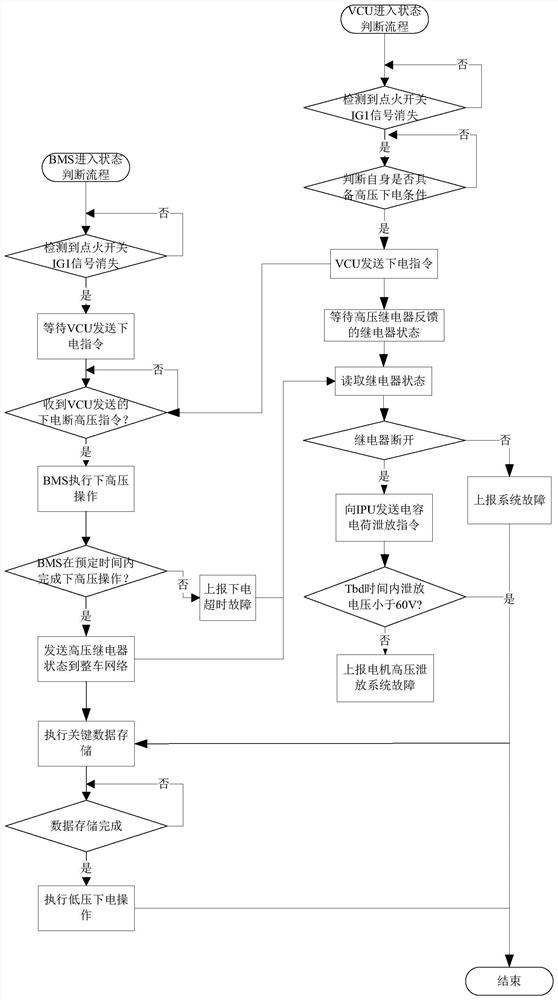

[0048] An embodiment of the present invention provides a method for powering off a battery management system, such as figure 1 As shown, the method includes:

[0049] S1. Detecting that the key signal IG1 disappears, the VCU (vehicle controller) judges whether the vehicle has the high-voltage power-off condition, and sends a power-off command;

[0050] S2. Detecting that the key signal IG1 disappears, the BMS (battery management system) waits for the VCU (vehicle controller) to send a power-off command;

[0051] S3. The BMS (battery management system) obtains the power-off command, executes the high-voltage operation and feeds back the status of the high-voltage relay to the VCU (vehicle controller);

[0052] S4. The VCU (vehicle controller) reads the status of the relay, and when it judges that the relay is disconnected, sends a capacitive charge discharge command to the IPU (integrated combined power unit);

[0053] S5. BMS (Battery Management System) performs key data sto...

Embodiment 2

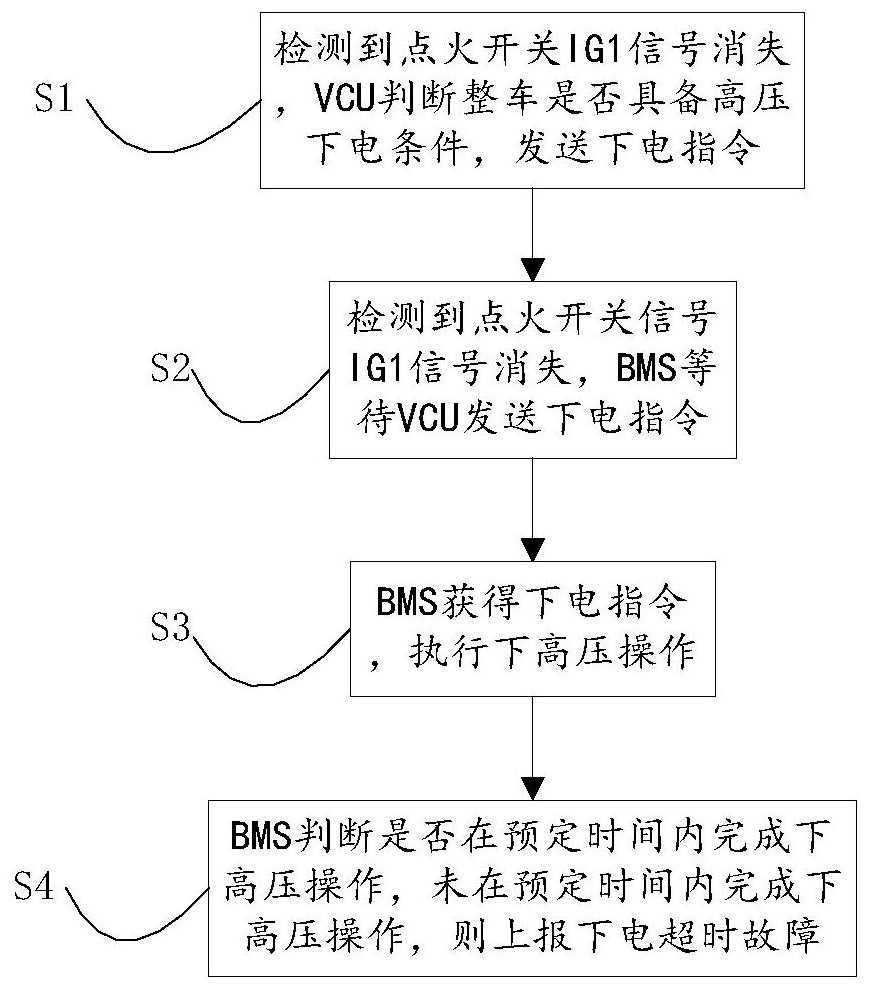

[0065] The embodiment of the present invention proposes a method for detecting a power-off timeout fault when the battery management system is powered off, such as image 3 As shown, the method includes:

[0066] S1. Detecting that the key signal IG1 disappears, the VCU (vehicle controller) judges whether the vehicle has the high-voltage power-off condition, and sends a power-off command;

[0067] S2. Detecting that the key signal IG1 disappears, the BMS (battery management system) waits for the VCU (vehicle controller) to send a power-off command;

[0068] S3. The BMS (battery management system) receives the power-off command and executes the high-voltage operation.

[0069] S4. The BMS (battery management system) judges whether the high-voltage operation is completed within the predetermined time, and if the high-voltage operation is not completed within the predetermined time, it will report a power-off overtime fault.

[0070] Specifically, until the BMS (battery managem...

Embodiment 3

[0075] The embodiment of the present invention proposes a method for detecting the fault that the relay is not disconnected when the battery management system is powered off, such as Figure 4 As shown, the method includes:

[0076] S1. Detecting that the key signal IG1 disappears, the VCU (vehicle controller) judges whether the vehicle has the high-voltage power-off condition, and sends a power-off command;

[0077] S2. Detecting that the key signal IG1 disappears, the BMS (battery management system) waits for the VCU (vehicle controller) to send a power-off command;

[0078] S3. The BMS (battery management system) obtains the power-off command and executes the high-voltage operation;

[0079] S4. The BMS (battery management system) fails to complete the high-voltage power-off operation within the predetermined time, and reports a power-off overtime fault. The high voltage relay is not disconnected;

[0080] S5. The VCU (vehicle controller) reads the status of the relay, j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com