A kind of preparation method of foamed metal-based lead alloy composite anode material

A foamed metal and composite anode technology, applied in metal material coating process, electrode, superimposed layer plating, etc., can solve the problems of metal ion sewage generation, unusable, poor density of lead dioxide or pure lead, etc., to achieve Energy saving, light weight, excellent oxygen evolution activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

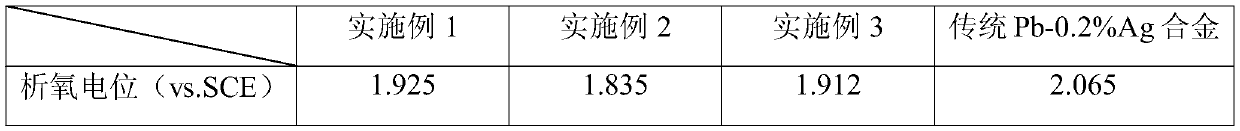

Examples

Embodiment 1

[0020] A method for preparing a foamed metal-based lead alloy composite anode material, the method steps are as follows:

[0021] (1) First put the aluminum foam with a porosity of 95%, an average main pore diameter of 0.5 mm, and a thickness of 1 mm on a ZXA045 full-automatic high-speed brush polishing machine, and polish it for 3 minutes to remove the oxide film on the surface of the aluminum foam. Rinse the surface of the foamed aluminum with a 10MPa high-pressure airflow in the dust box. After the substrate is cleaned, place it in a ZCK-1400 vacuum magnetron sputtering coating equipment, and sputter and coat tin-bismuth with a thickness of 0.2 μm on the surface of the foamed aluminum. Alloy layer;

[0022] (2) Under the protection of an argon atmosphere, put the Pb-0.2%Ag alloy into a vacuum microgravity melting furnace, and the furnace temperature is controlled at 350°C. After the Pb-0.2%Ag alloy is completely melted, weigh the SnO 2 Add Pb-0.2%Ag alloy melt, where SnO ...

Embodiment 2

[0025] A method for preparing a foamed metal-based lead alloy composite anode material, the method steps are as follows:

[0026] (1) Put the foamed copper with a porosity of 75%, an average main pore diameter of 1.0 mm, and a thickness of 5 mm on a ZXA045 automatic high-speed brush polishing machine, and polish it for 5 minutes to remove the oxide film on the surface of the foamed copper. Rinse the foamed copper surface with 10MPa high-pressure airflow in the box, and after the substrate is cleaned, place it in a ZCK-1400 vacuum magnetron sputtering coating equipment, and sputter-plate a tin-bismuth alloy layer with a thickness of 1 μm on the foamed copper surface ;

[0027] (2) Under the protection of an argon atmosphere, put the Pb-0.2%Ag alloy into a vacuum microgravity melting furnace, and the furnace temperature is controlled at 400°C. After the Pb-0.2%Ag alloy is completely melted, weigh the RuO 2 Added to the lead alloy melt, where RuO 2 Occupying 0.05% of the mass ...

Embodiment 3

[0030] A method for preparing a foamed metal-based lead alloy composite anode material, the method steps are as follows:

[0031](1) First put the foamed nickel with a porosity of 85%, an average main pore diameter of 0.8mm, and a thickness of 3mm on a ZXA045 full-automatic high-speed brush polishing machine, and polish it for 5 minutes to remove the oxide film on the surface of the foamed nickel. Rinse the foamed nickel surface with 10MPa high-pressure airflow in the box. After the substrate is cleaned, place it in a ZCK-1400 vacuum magnetron sputtering coating equipment, and sputter and coat a tin-bismuth alloy layer with a thickness of 3 μm on the foamed nickel surface. ;

[0032] (2) Under the protection of an argon atmosphere, put the Pb-0.2%Ag alloy into a vacuum microgravity melting furnace, and the furnace temperature is controlled at 450°C. After the Pb-0.2%Ag alloy is completely melted, weigh the γ-MnO 2 or β-MnO 2 Added to lead alloy melt, in which γ-MnO 2 or β-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com