Electric-conductivity type sludge specific resistance measuring apparatus

A technology for measuring device and sludge specific resistance, which is applied in the direction of material resistance, etc., can solve the problems of cumbersome and time-consuming processing operations, achieve broad application prospects, easy operation, and avoid manual recording errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further elaborated, but should note that these embodiments are only used to illustrate the present invention and do not limit the scope of the present invention, those skilled in the art after having read the detailed content of the present invention, to this invention Various changes or modifications made in the invention should fall within the limited scope of the invention.

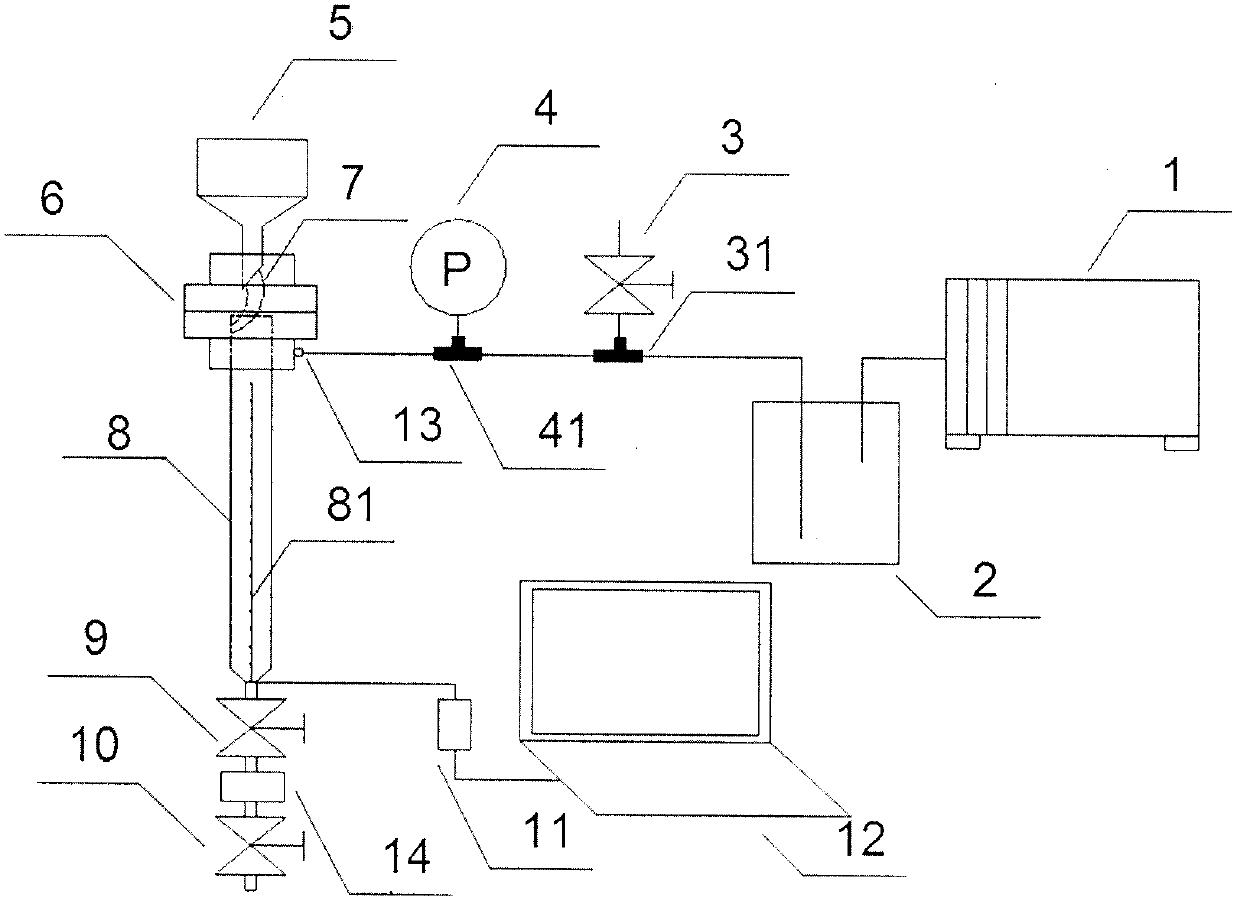

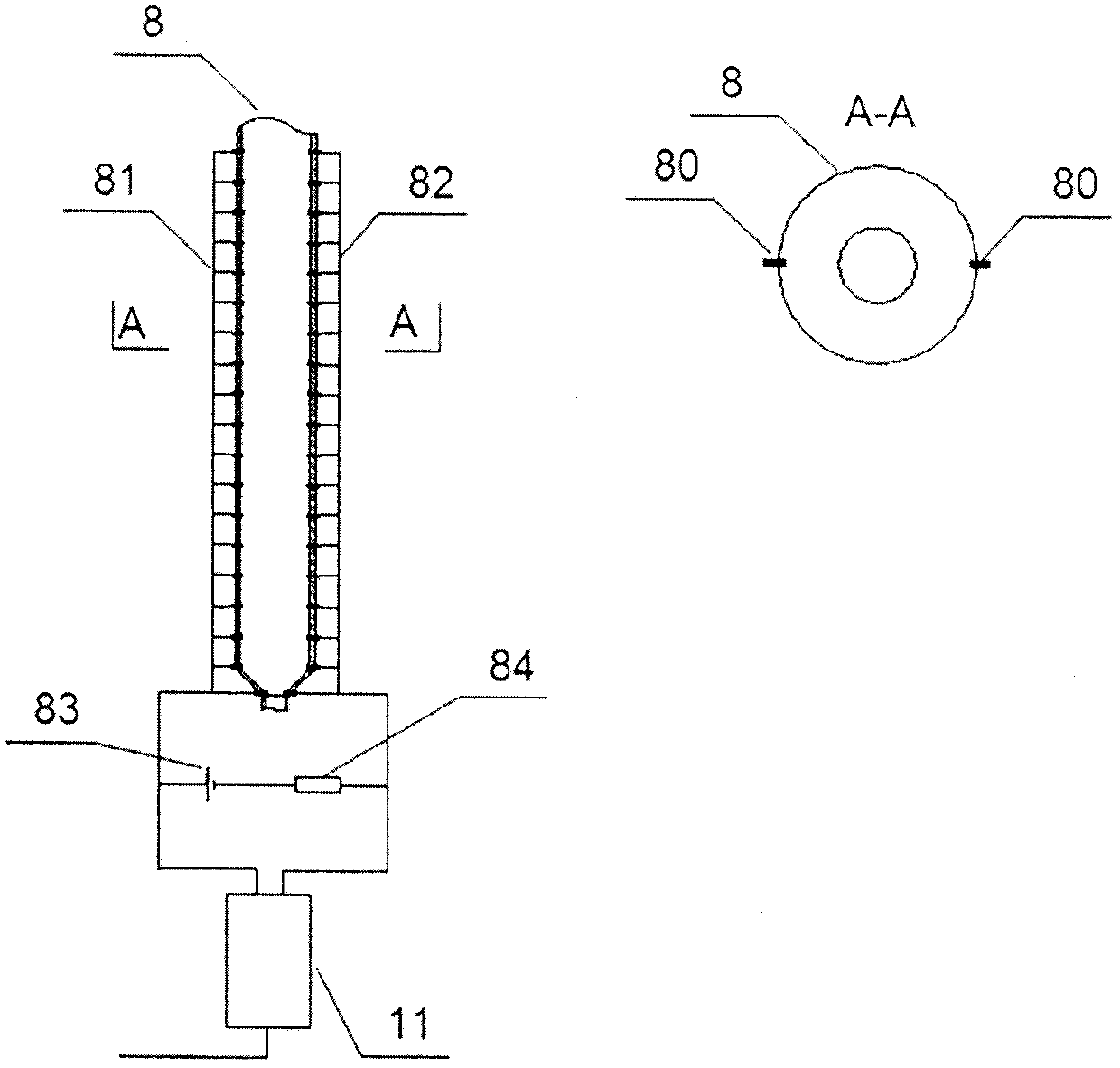

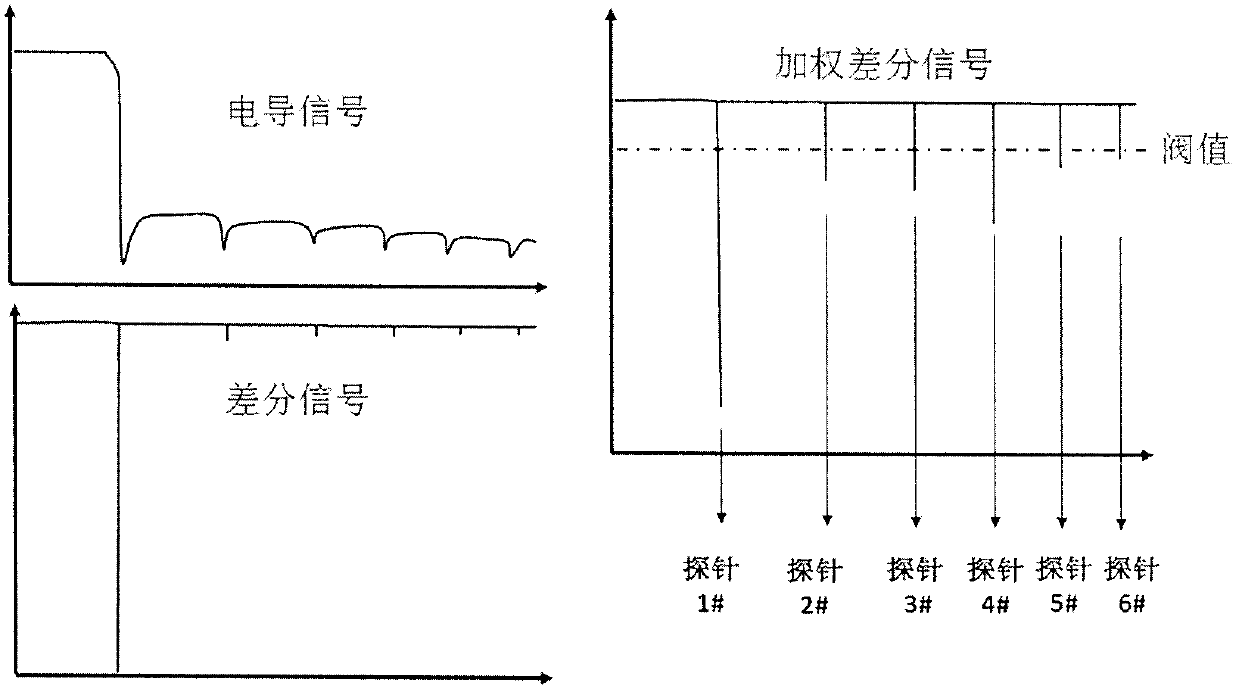

[0021] Embodiment 1 of a conductive sludge specific resistance measuring device of the present invention: as figure 1 As shown, the present invention consists of a vacuum pump 1, a buffer bottle 2, a regulating valve 3, a tee 31, a tee 32, a vacuum gauge 4, a Buchner funnel 5, a joint 6, a draft tube 7, an air extraction port 13, and a measuring tube 8 , conductance array probe 81, conductance array probe 82, constant voltage power supply 83, resistor 84, data acquisition card 11, computer 12, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com