Device and method for exchanging a gas from a working chamber of a walk-in inert-gas housing

An inert gas, studio technology, applied in chemical instruments and methods, cleaning methods and utensils, applications, etc., can solve the problems of huge sensor wiring and control costs, and achieve the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

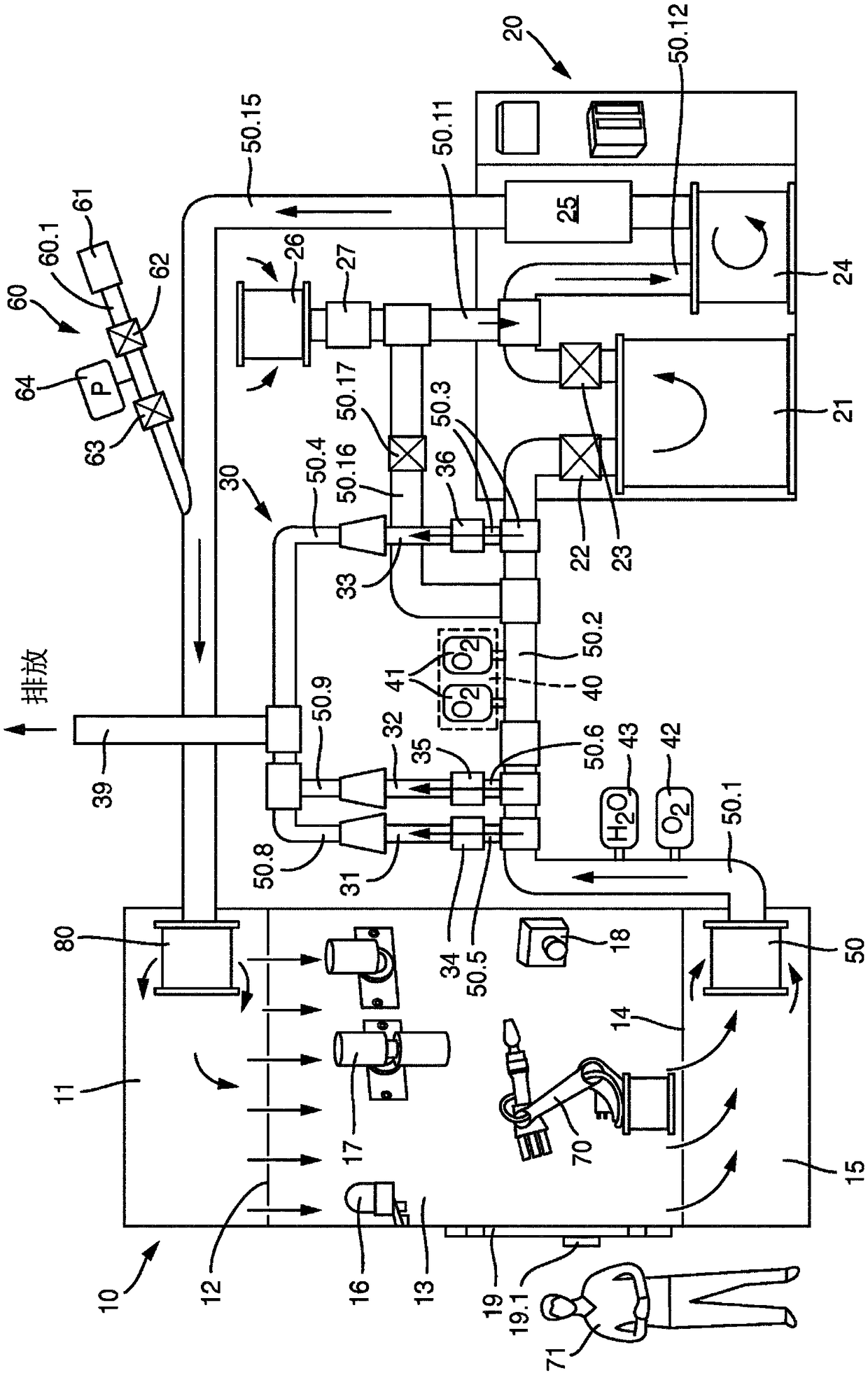

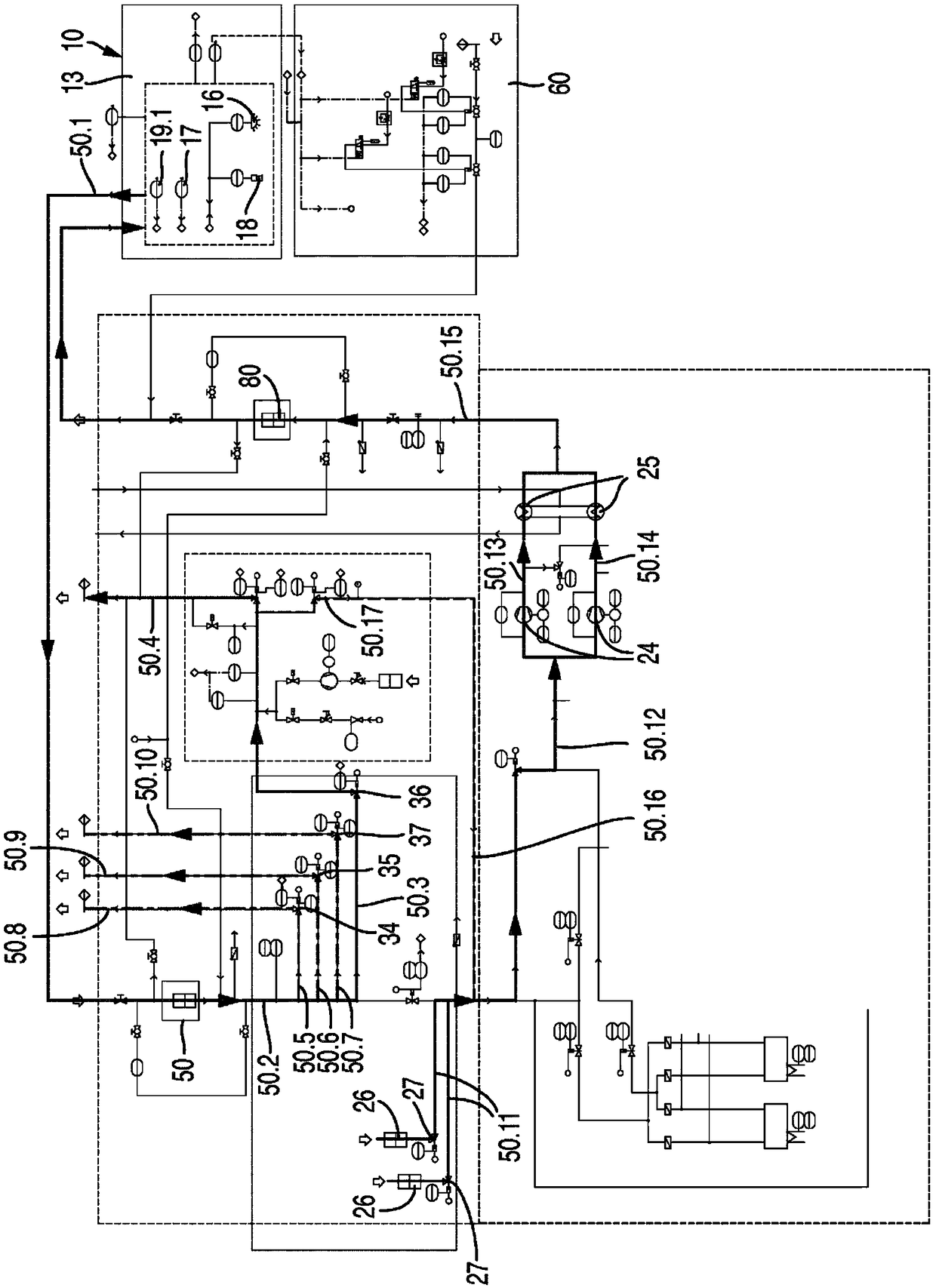

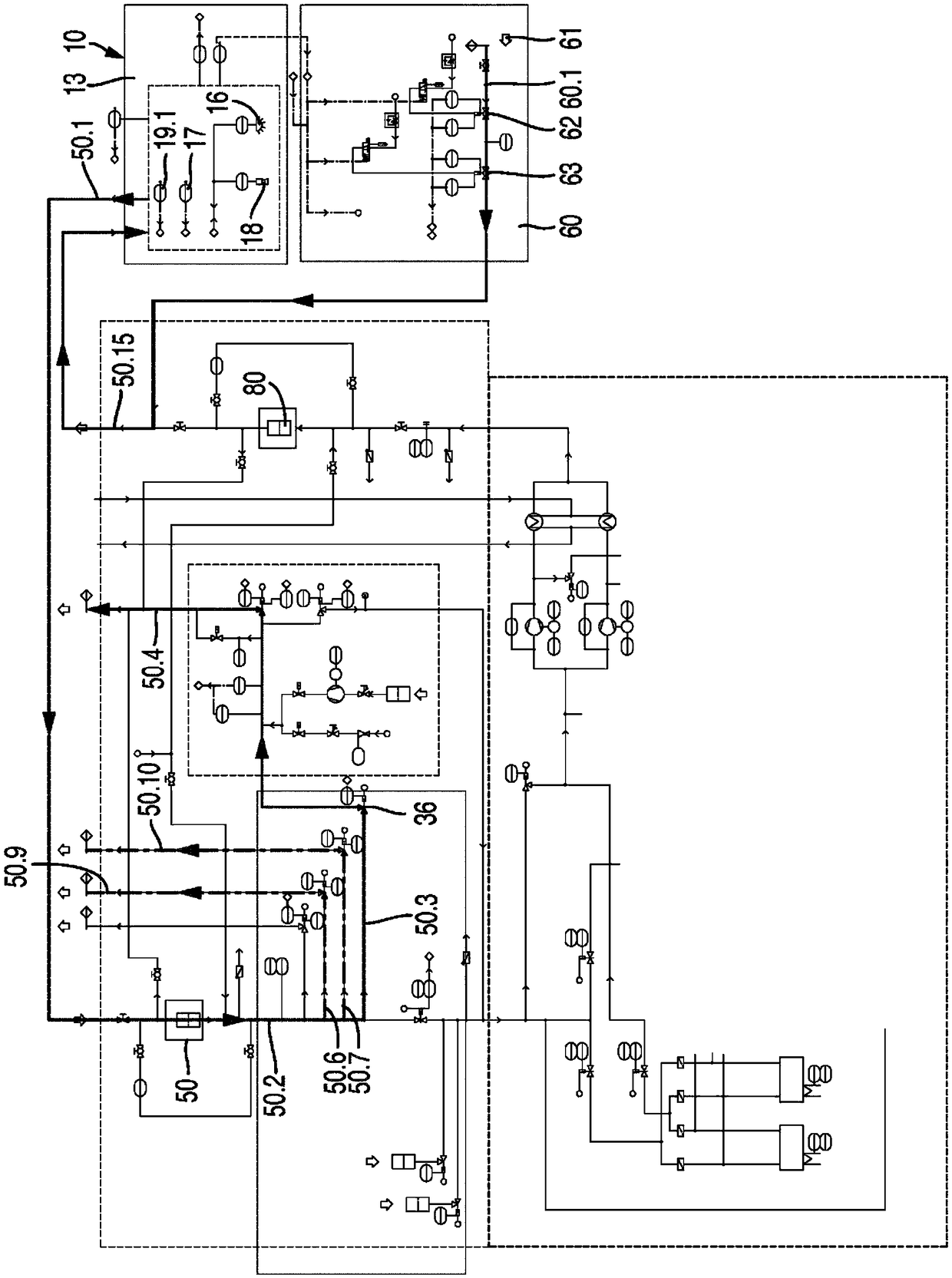

[0026] figure 1 Illustratively, a repairable inert gas housing 10 is shown. Such an inert gas shell 10 is used, for example, to contain production equipment, by means of which production processes can be carried out in a protected atmosphere. As the inert gas, for example, nitrogen or argon can be used.

[0027] The inert gas housing 10 has a working chamber 13 in which production equipment, such as a machine 70, is installed. Usually use fully automatic operation equipment in the inert gas shell, such as figure 1 Visible in. in figure 1 In the shown inert gas housing 10 above the working chamber 13, a plenum 11 is separated by a cover 12. In the bottom area of the inert gas housing 10, the chamber 15 is divided by the bottom 14. Of course, the present invention can also be used in inert gas shells 10 of different configurations, in which, for example, the pressure ventilation system 11 is not used or the bottom side chamber 15 is not used. The inert gas housing 10 has a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com