Precipitator with variable precipitation area for sugaring

A settler and variable technology, applied in the settling tank, sedimentation adjustment device, application and other directions, can solve the problem of not being able to adjust the settlement area and working volume at the same time, and achieve the effect of reducing sedimentation, saving foundation area and facilitating layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific drawings.

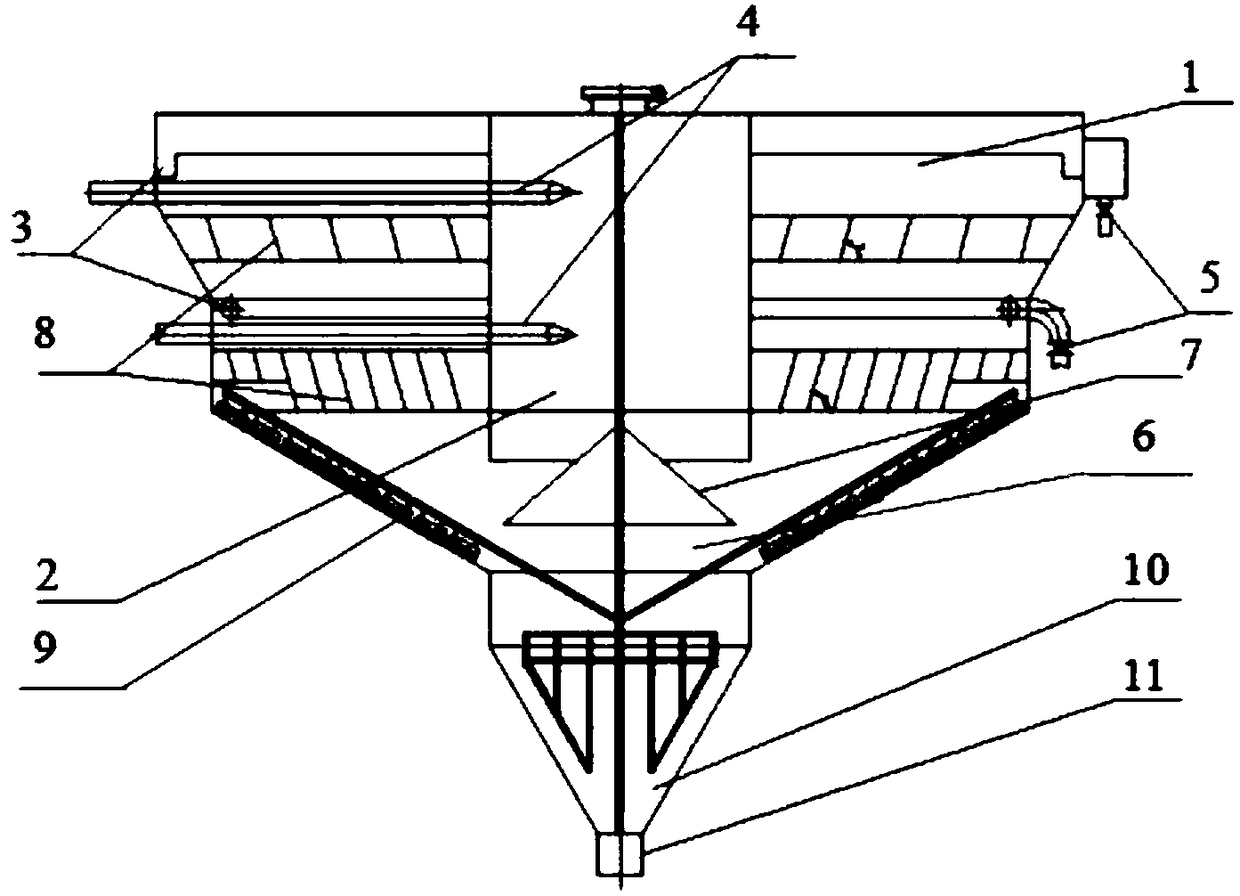

[0023] like figure 1 As shown, the present invention provides a kind of settler for sugar making with variable settling area, characterized in that, the settler cylinder (1) is set to be spliced by at least two cylinders whose diameters are large and small, and the settler The cylinder (1) contains at least one conical cylinder; the center of the settler cylinder (1) is provided with a central downcomer (2) with an open lower end, and the juice inlet pipe (3) is connected to the central downcomer (2); At least two layers of clear juice collection rings (4) at different levels are arranged in the barrel (1), and a clear juice valve (5) is arranged on the clear juice collection rings (4); at the lower end of the settler barrel (1) Attach a sludge collection cone (6). The working process of this device: the sugar juice added with flocculant enters the central downcomer (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com