Feeding mechanism of numerically controlled lathe

A feeding mechanism and technology of CNC lathes, applied in the field of lathes, can solve problems such as increasing the labor force of the staff, friction damage on the inner wall of the propulsion tube, and affecting the air pressure conveying of the bar, so as to achieve convenient and timely detection and maintenance, not easy to loosen, and the feeding action stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

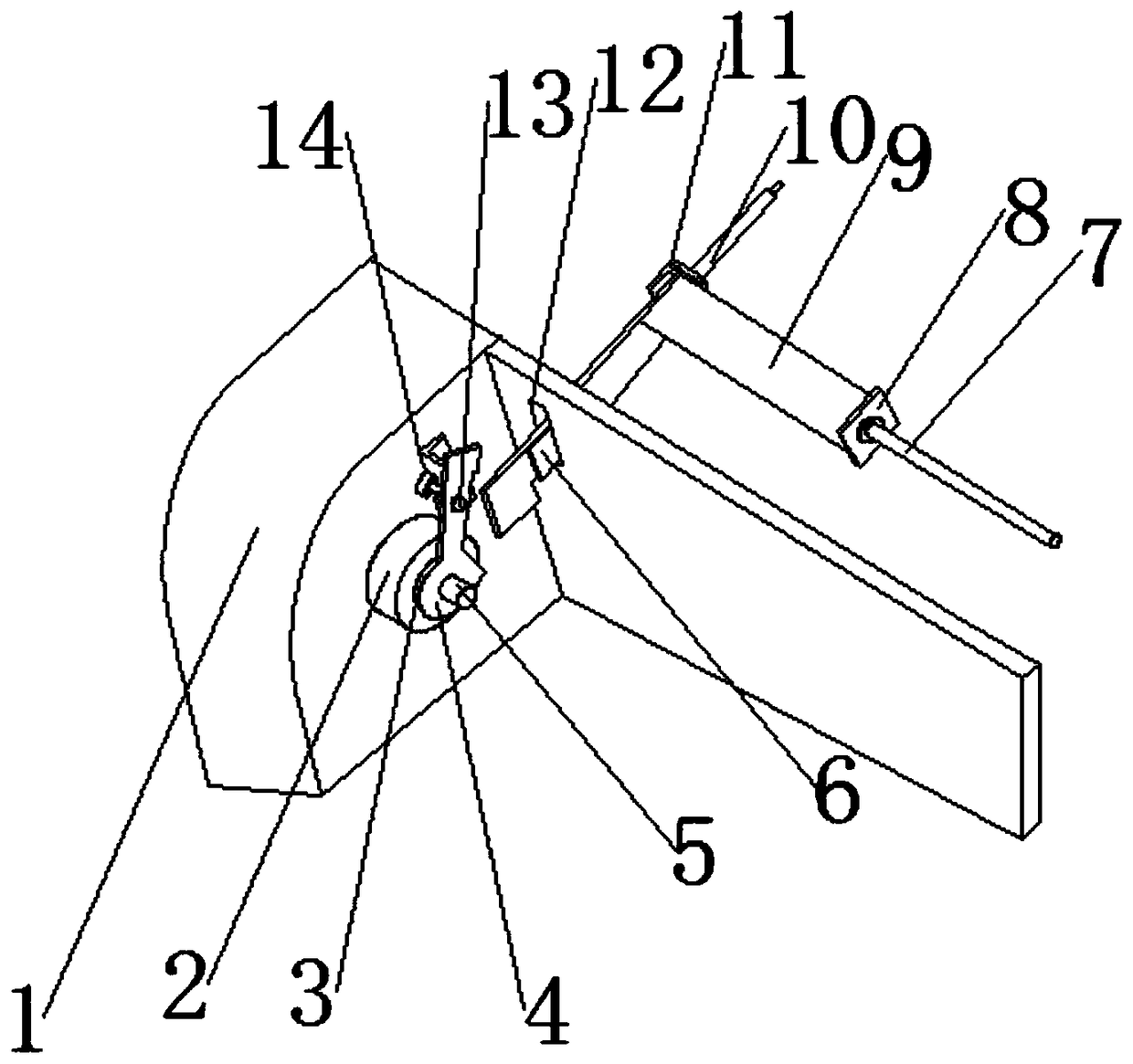

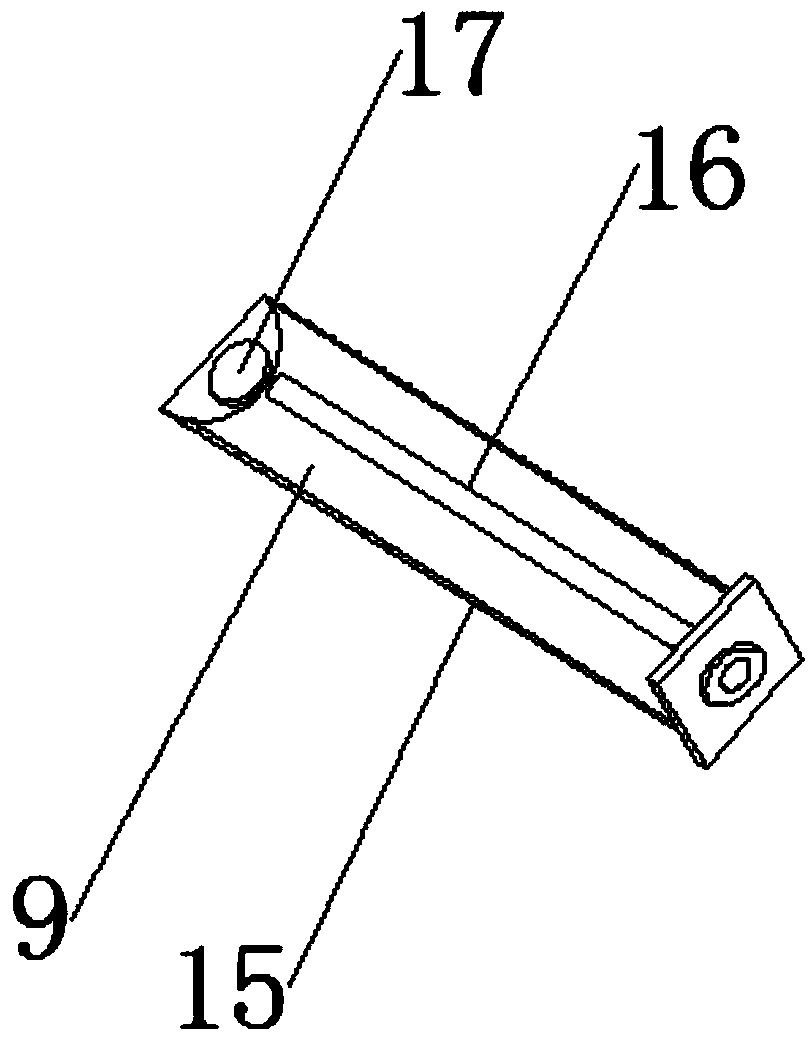

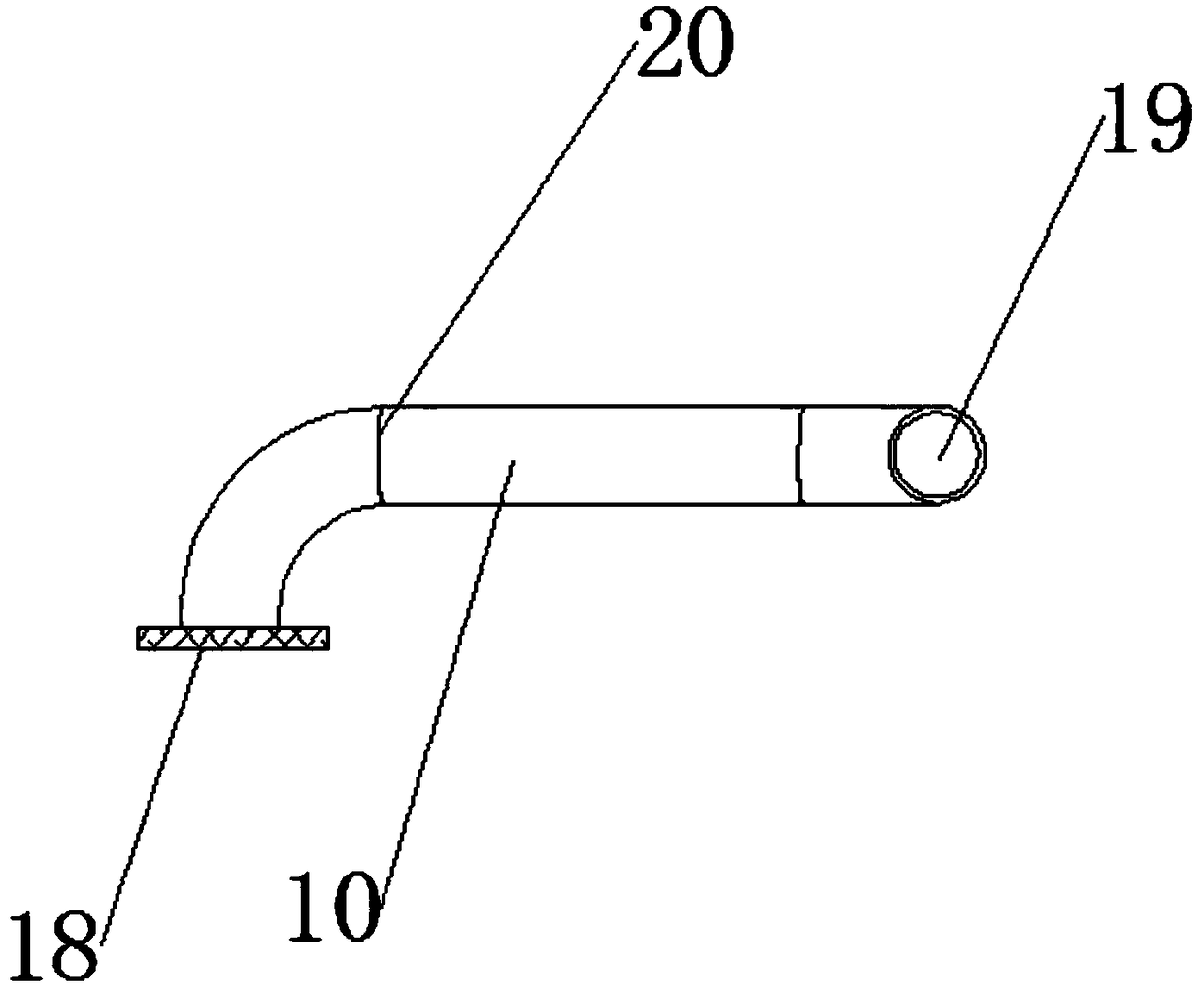

[0020] Example 1: See Figure 1-3 , the present invention provides a technical solution: a feeding mechanism of a numerically controlled lathe, comprising a feeding body 1, one side of the feeding body 1 is provided with a storage tube 2, and the other side of the storage tube 2 is provided with a push rod 4, The inside of the storage pipe 2 is provided with a material inlet 3, one side of the push rod 4 is provided with a gravity sensor 5, the end of the push rod 4 is provided with a baffle 14, and the middle of the push rod 4 is provided with a shaft 13 One end of the storage pipe 2 is provided with a discharge interface 6, the outer wall of the discharge interface 6 is provided with a hole 12, the end of the discharge interface 6 is provided with a connector 11, and one side of the connector 11 is provided with a propulsion tube 9, The other side of the propulsion tube 9 is provided with an end cover 8, one end of the connector 11 is provided with a gas collecting pipe 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com