Connecting mechanism of solid wood floor blocks for radiant ground heating and machining method thereof

A connection mechanism and solid wood flooring technology, applied in wood processing equipment, manufacturing tools, etc., can solve the problems of more severe lock connection strength test, waste of time for preparation and installation, unfavorable heat of keel method, etc., to achieve excellent pavement firmness Safety, improve living comfort, superior noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

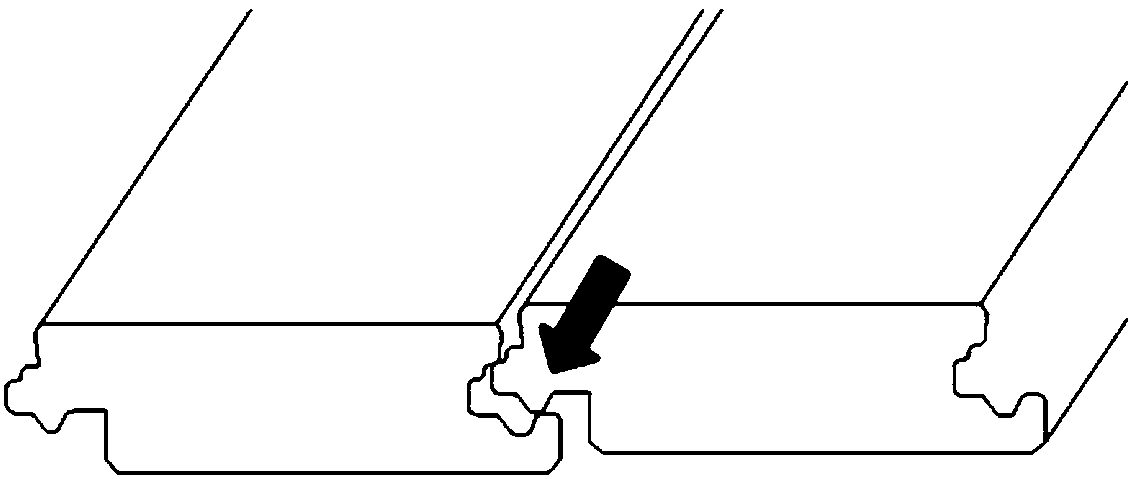

[0023] Below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 As shown in the figure, the two floorboards with the connection mechanism have been processed, and a force is applied by tilting, and the tenon of the floorboard slides into the tenon of the other floorboard, which is quick and easy to install.

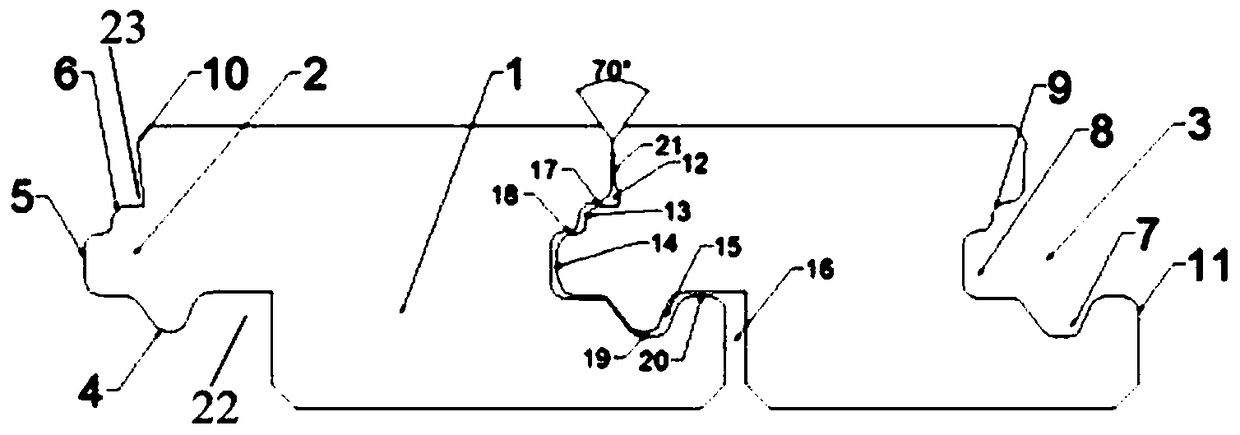

[0024] Such as figure 2 As shown, the solid wood floor board provided by the present invention and the adjacent floor boards are fastened to each other through the connecting mechanism to form a complete solid wood floor board. The tenon 2 and the tenon groove 3 are machined on both sides in the length direction, and the tenon 2 has a first bump 4, a second bump 5 and a third bump 6 protruding along the width and thickness of the floor, respectively. The tongue and groove 3 has a first groove 7, a second groove 8 and a third groove 9 which are respectively depressed along the width and thickness directions of the floor; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com