Pipe winding mechanism for cement soil mixing pile machine

A technology for cement-soil mixing piles and pipelines, applied in the field of pipeline coiling mechanisms, can solve the problems of inability to drill a drill pipe, difficult drilling, long power transmission stroke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

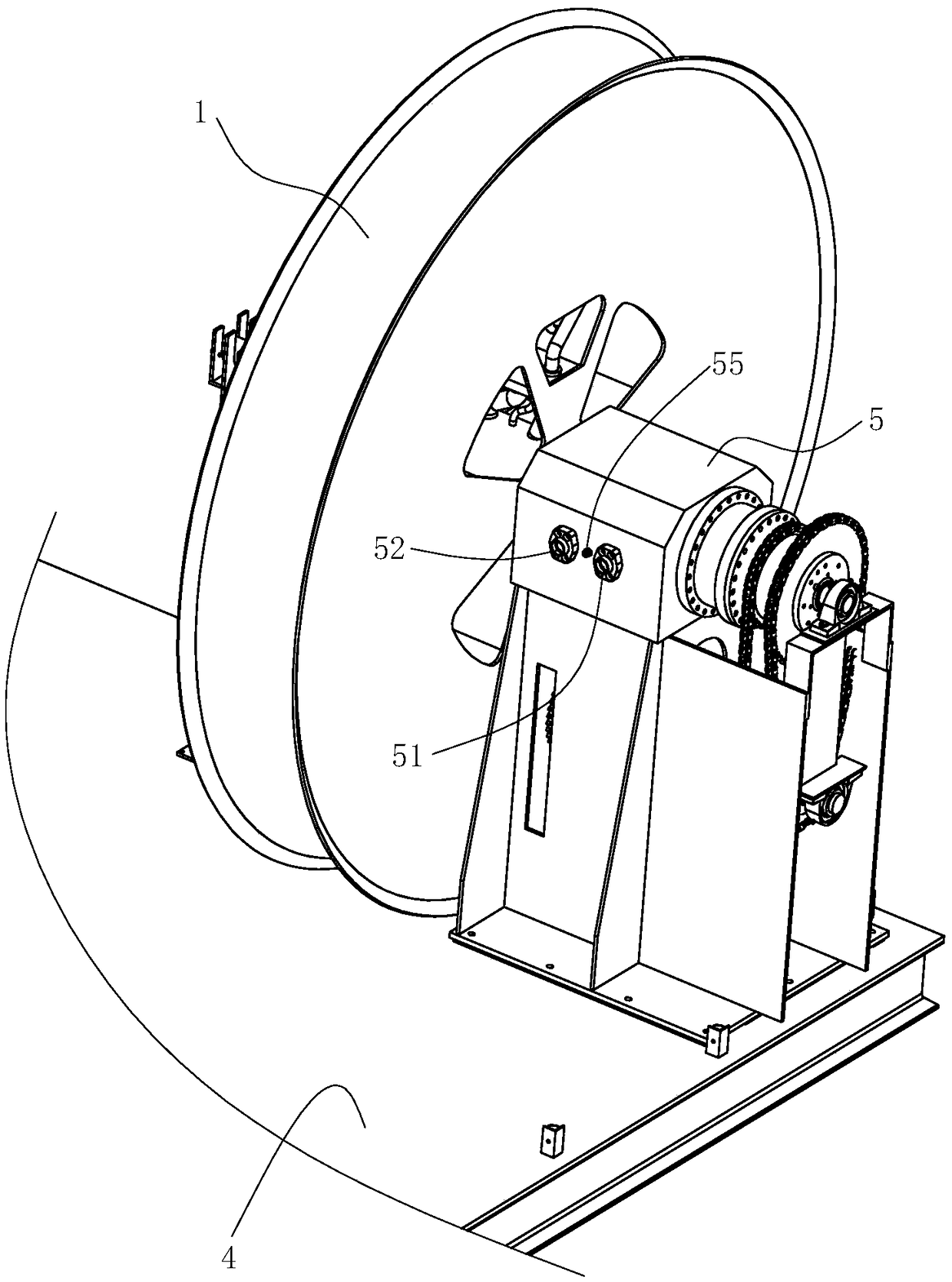

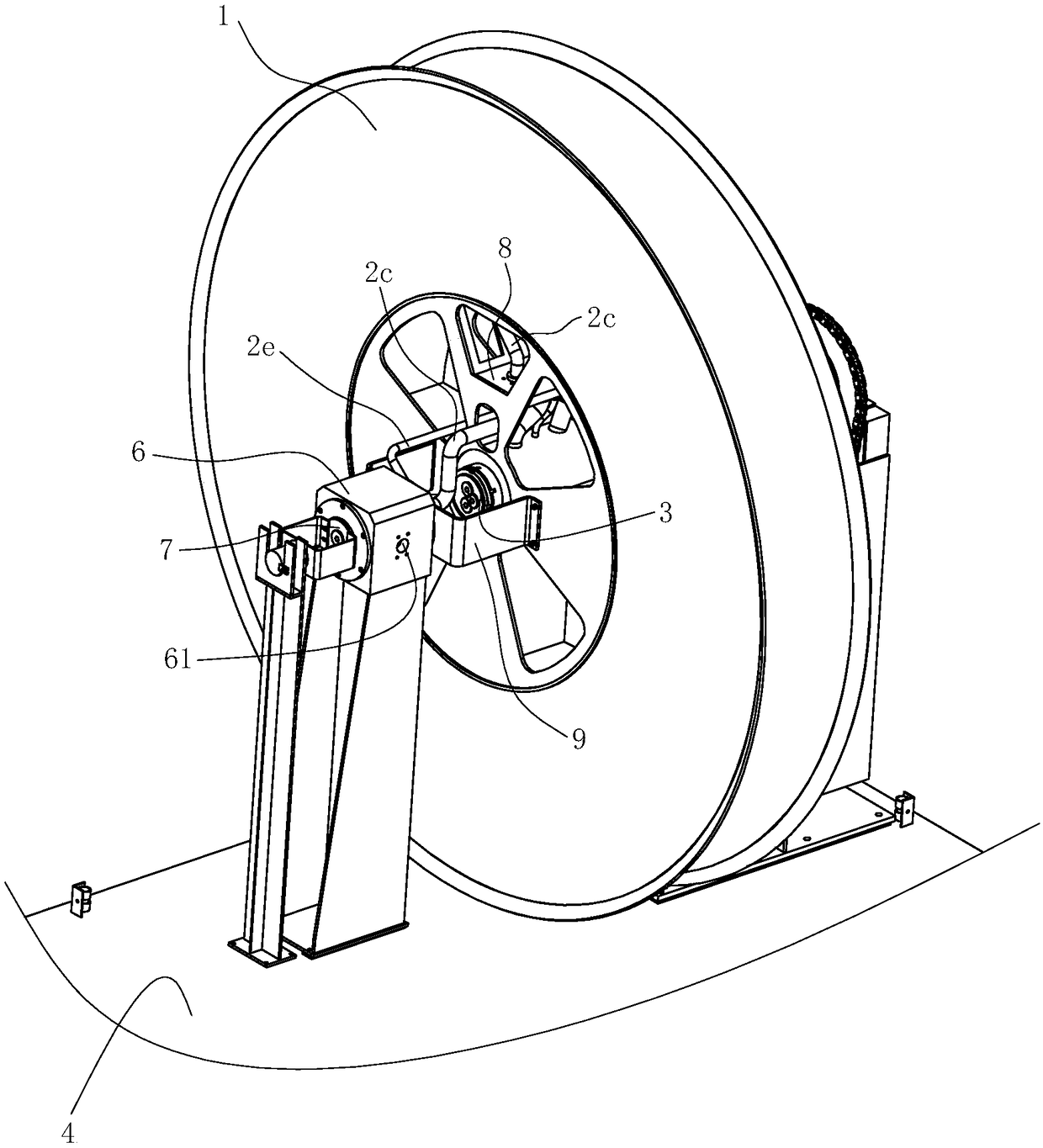

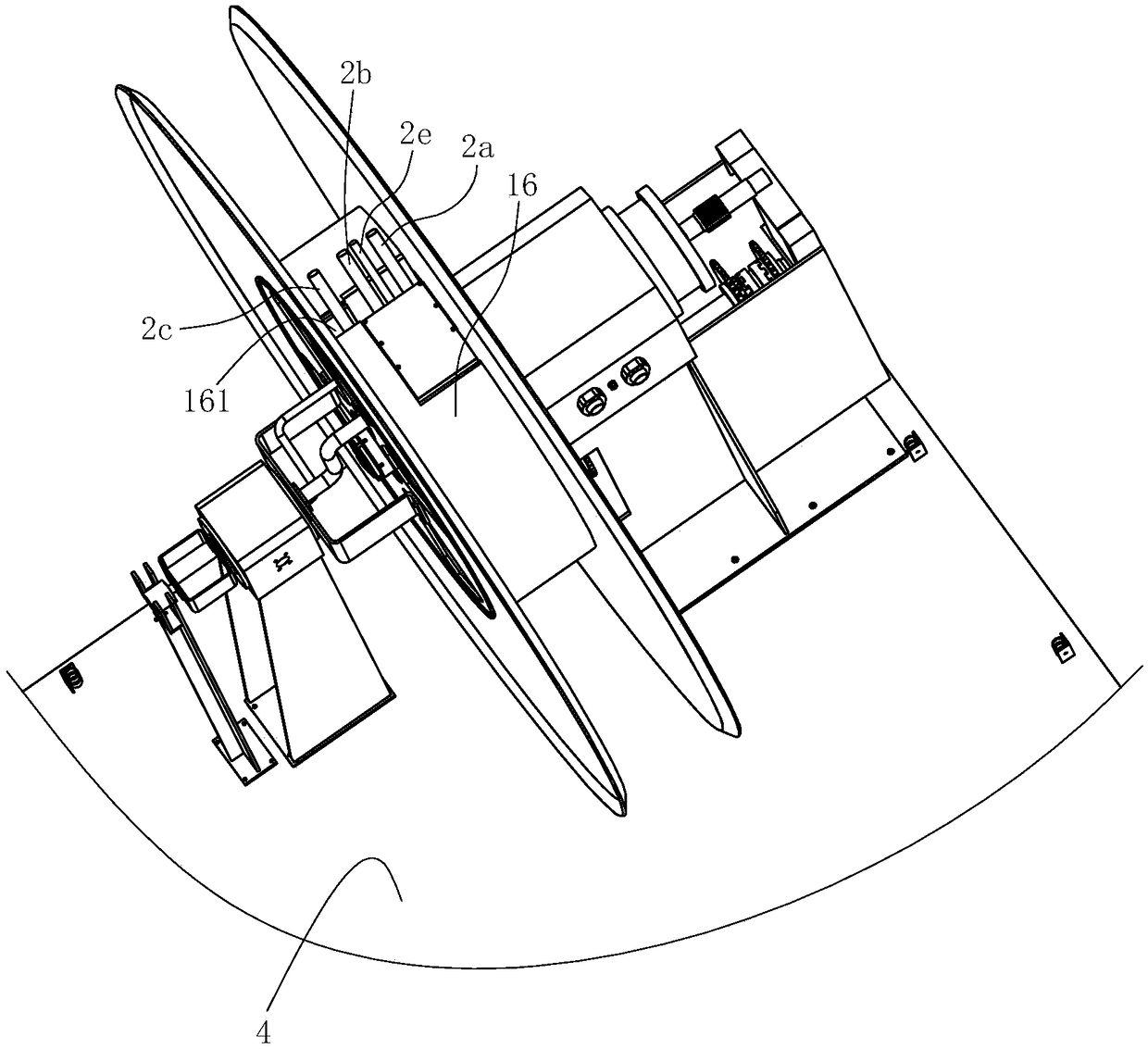

[0025] like Figure 1~6 Shown is a preferred embodiment of the present invention.

[0026] A pipeline coiling mechanism for a cement-soil mixing pile machine, characterized in that it includes

[0027]The wire reel 1, the inner hole of the wire reel 1 is pierced and fixed with a transmission shaft 3, and the wire reel 1 is fixed with an oil inlet pipe 2a and an oil outlet pipe that are always connected with the inner hole of the wire reel 1 2b and the oil discharge pipe 2d, the oil inlet pipe 2a, the oil outlet pipe 2b and the oil discharge pipe 2d all protrude from the coil wire peripheral surface of the coil coil drum 1.

[0028] The first support 5 is fixed on the cement-soil mixing pile machine platform 4. The transmission shaft 3 is passed through and supported in the first support 5 by bearings to rotate around its own axis. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com