Method for applying powder on fluorescence lamp and its device

A fluorescent lamp and adjusting device technology, which is applied in the application of luminescent paint, tube/lamp screen manufacturing, and drying of solid materials, etc. It can solve the problems of large space occupied by the baking powder device, non-flowing flow speed of powder slurry, and low temperature accuracy control. , to achieve the effect of simple structure, fast flow speed and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A device for powdering a fluorescent lamp, comprising a powder coating device and a powder baking device, wherein the powder coating device is used for coating powder slurry on the inner wall of the powder tube; the powder baking device is used for drying and making the powder slurry adhere to the inner wall of the powder tube.

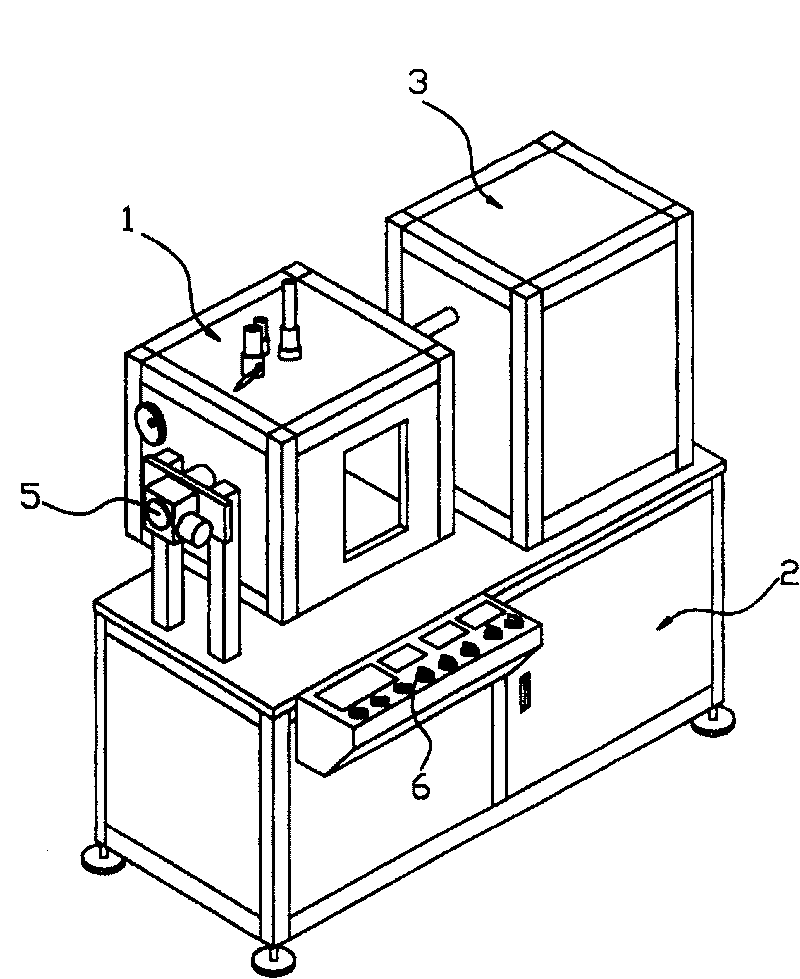

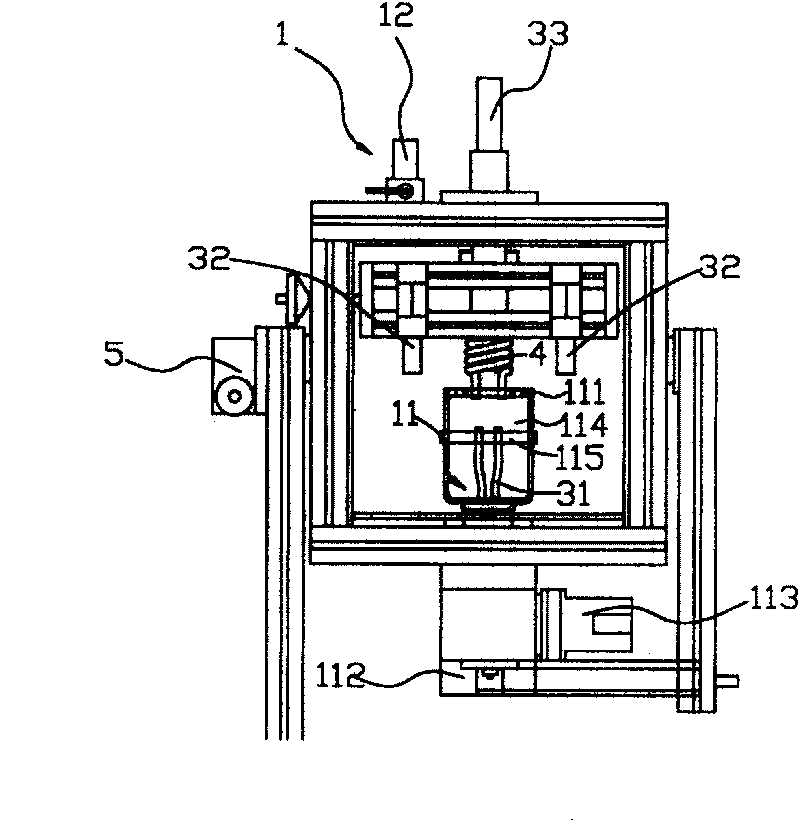

[0041] Such as figure 1 , 2 , 3, the baking powder device includes a baking powder cavity 1, a base 2 and a heating system 3 located outside the baking powder cavity 1.

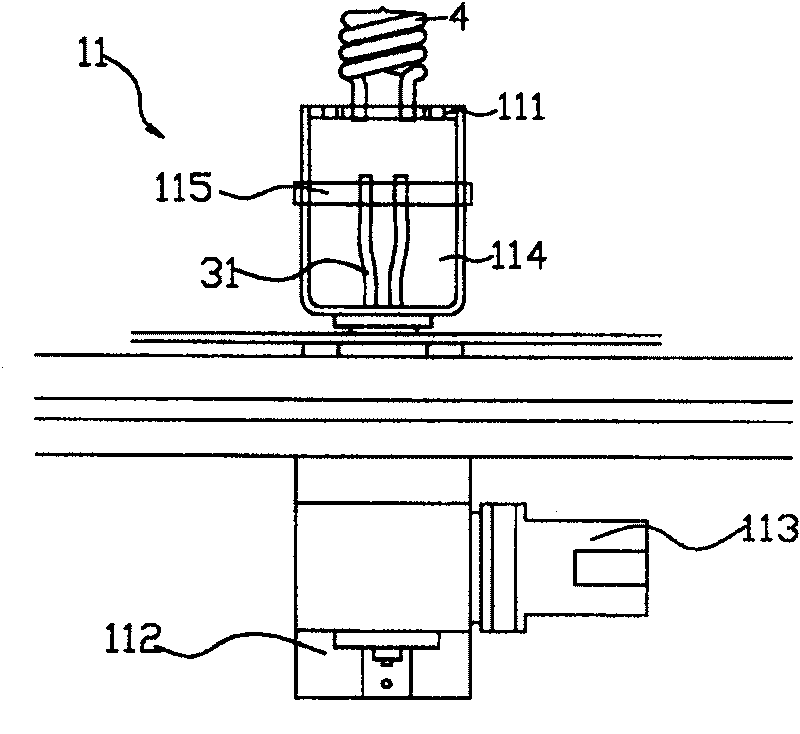

[0042] A powder tube rotation mechanism 11 is arranged inside the baking powder cavity 1 , and the powder tube rotation mechanism includes a rotation sleeve 114 , a powder tube clamp 111 , a double joint 112 and a stepping motor 113 .

[0043] The powder pipe clamp 111 is used to clamp the powder pipe 4. Considering the manual placement of workpieces and the dimensional accuracy of the powder pipe 4, the powder pipe clamp 111 in this embodiment adopts a simple elastic fast cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com