Preparation method of bismuth oxychloride photocatalyst

A technology of photocatalyst and bismuth oxychloride, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of not improving the reaction efficiency, and achieve easy control of the reaction process, low production cost, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1

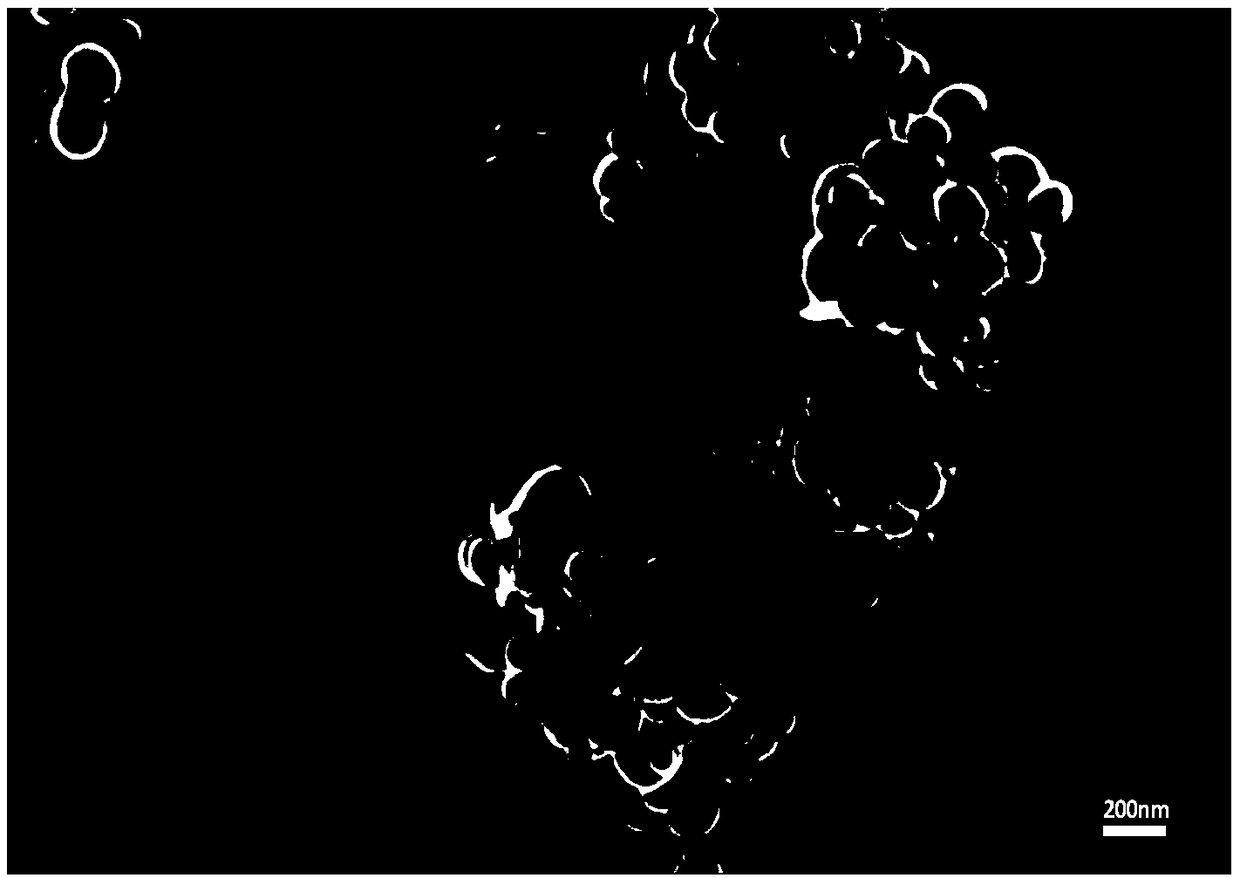

[0019] The preparation method of the bismuth oxychloride catalyst of the present embodiment includes the following steps: 1) adding 30g of commercially available analytically pure bismuth oxide, 100ml of water and a nodular ink medium into a tank at room temperature, the ball milling speed is 400rpm, and the ball mill is carried out in a planetary ball mill. 6h. Release the slurry and filter the mixed ball-milling medium with a 120-mesh screen, pour the obtained suspension into a beaker, let it stand for 1 hour at room temperature in a vacuum drying oven, pour out the upper layer liquid, and store the remaining material in the beaker at 60°C in a vacuum drying oven Dry under vacuum for 8h to obtain bismuth oxide with a particle size of 160nm, such as figure 1 As shown in the figure, it can be seen from the figure that the particle size of the ground bismuth peroxide is uniform, the surface is smooth, and the particle size is within the range required by the...

Example Embodiment

[0020] Example 2

[0021] The preparation method of the bismuth oxychloride catalyst of the present embodiment includes the following steps: 1) adding 30g of commercially available analytically pure bismuth oxide, 50ml of water and a nodular ink medium into a tank at room temperature, the ball milling speed is 500rpm, and the ball mill is carried out in a planetary ball mill. 10h. Release the slurry and filter the mixed ball-milling medium with a 120-mesh screen, pour the obtained suspension into a beaker, let it stand for 1 hour at room temperature in a vacuum drying oven, pour out the upper layer liquid, and store the remaining material in the beaker at 80°C in a vacuum drying oven Dry under vacuum for 10 h to obtain bismuth oxide with a particle size of 100 nm. 2) Add 1 g of bismuth oxide with a particle size of 100 nm to 25 ml of sodium chloride solution, the concentration of the sodium chloride solution is 0.5 mol / L, and stir at room temperature for 6 hours; 3) First add...

Example Embodiment

[0022] Example 3

[0023] The preparation method of the bismuth oxychloride catalyst of the present embodiment includes the following steps: 1) adding 30g of commercially available analytically pure bismuth oxide, 30ml of water and a nodular ink medium into a tank at room temperature, the ball milling speed is 800rpm, and the ball mill is carried out in a planetary ball mill. 12h. Release the slurry and filter the mixed ball-milling medium with a 120-mesh screen, pour the obtained suspension into a beaker, let it stand for 1 hour at room temperature in a vacuum drying oven, pour out the upper layer liquid, and store the remaining material in the beaker at 80°C in a vacuum drying oven Dry under vacuum for 12 h to obtain bismuth oxide with a particle size of 80 nm. 2) Add 1g of bismuth oxide with a particle size of 80nm to 15ml of sodium chloride solution, the concentration of sodium chloride solution is 2mol / L, and stir at room temperature for 12h; 3) The precipitate obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com