Ammonia nitrogen wastewater treating method and device

A technology for ammonia nitrogen wastewater and treatment equipment, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of large amount of precipitation chemicals, secondary pollution, and breakpoint chlorination operation High costs and other issues, to achieve the effect of saving pharmaceutical costs and improving hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

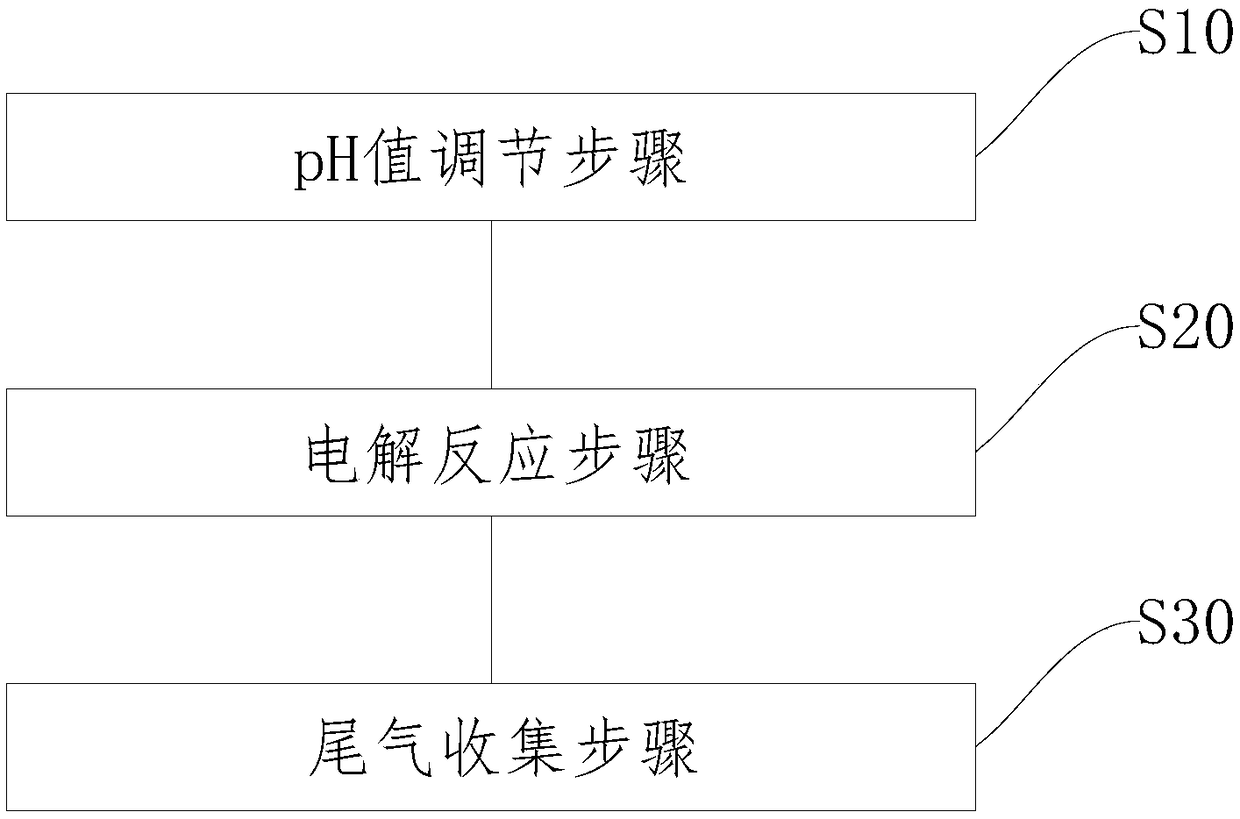

[0040] Please refer to Figure 1 to Figure 4 , This embodiment provides a treatment method for ammonia nitrogen wastewater, which can effectively remove ammonia nitrogen in ammonia nitrogen wastewater, and improve the harm caused by the discharge of ammonia nitrogen wastewater into water bodies.

[0041] The ammonia nitrogen wastewater treatment method provided in this embodiment includes: a pH adjustment step S10, an electrolysis reaction step S20, and a tail gas collection step S30.

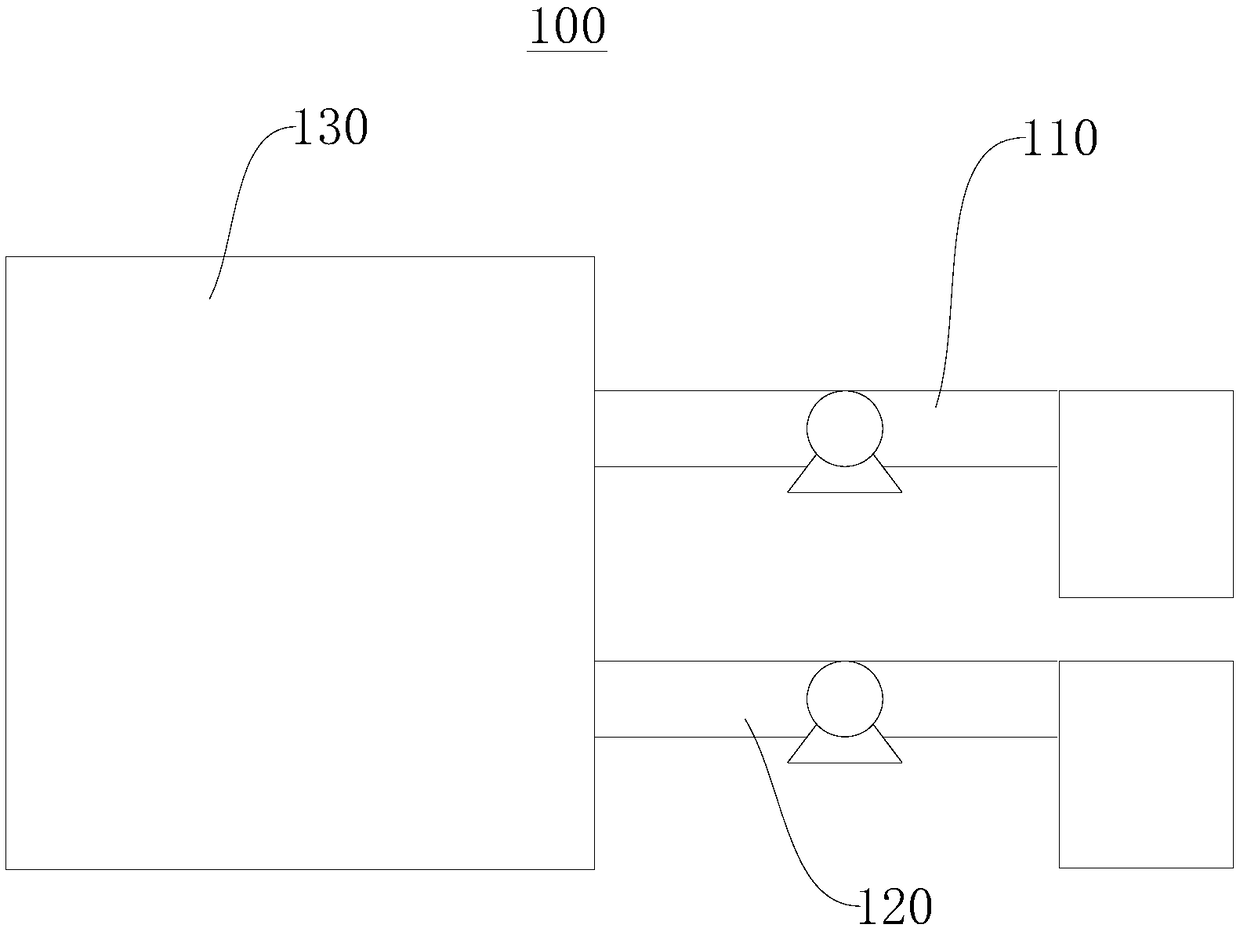

[0042] S10: pH adjustment step. The pH value of the ammonia nitrogen wastewater accommodated in the pH value adjusting device 100 is adjusted.

[0043] In this embodiment, the pH adjustment step includes: adding an acidic solution to the ammonia nitrogen wastewater through the first dosing pump 110, or adding an alkaline solution to the ammonia nitrogen wastewater through the second dosing pump 120, to adjust the pH of the ammonia nitrogen wastewater value.

[0044]S20: electrolysis reaction...

no. 2 example

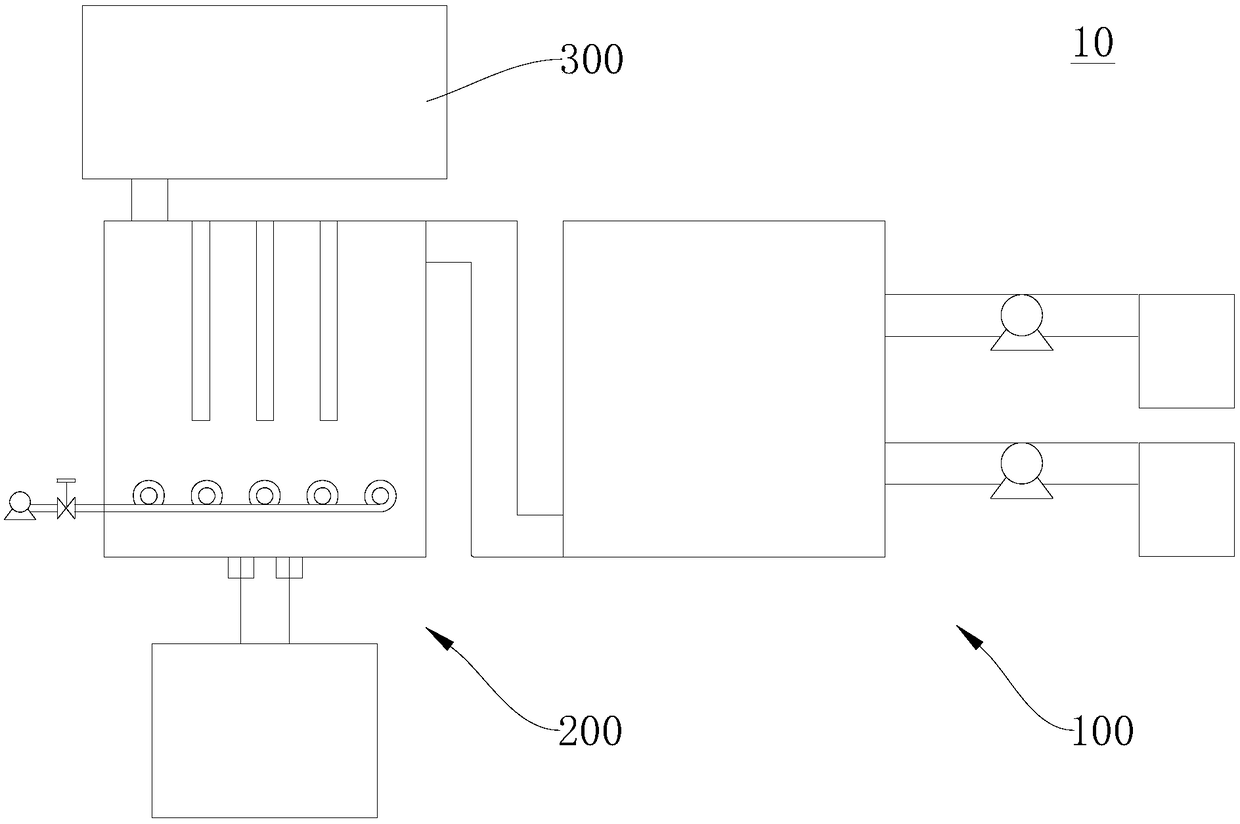

[0049] see Figure 1 to Figure 4 , the present embodiment provides an ammonia nitrogen wastewater treatment device 10, which can effectively remove ammonia nitrogen in the ammonia nitrogen wastewater, and improve the harm caused by the discharge of the ammonia nitrogen wastewater into the water body.

[0050] This embodiment provides an ammonia nitrogen wastewater treatment device 10 for implementing the ammonia nitrogen wastewater treatment method provided in the first embodiment. The ammonia nitrogen wastewater treatment method includes: a pH value adjustment step: adjusting the pH value of the ammonia nitrogen wastewater contained in the pH value adjustment device 100; an electrolytic reaction step: introducing the ammonia nitrogen wastewater that has undergone the pH value adjustment step into the electrolytic oxidation device 200, And carry out the electrolysis reaction; the exhaust gas collection step: the gas generated in the electrolysis reaction step is introduced int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com