Quick dewatering and solidifying apparatus for river sludge

A solidifying device and rapid dewatering technology, applied in water/sludge/sewage treatment, fixed/solidified sludge treatment, dewatering/drying/concentrated sludge treatment, etc. The strength of silt soil is unstable and other problems, to achieve the effect of speeding up infrastructure construction and economic development, excellent curing effect, and short curing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

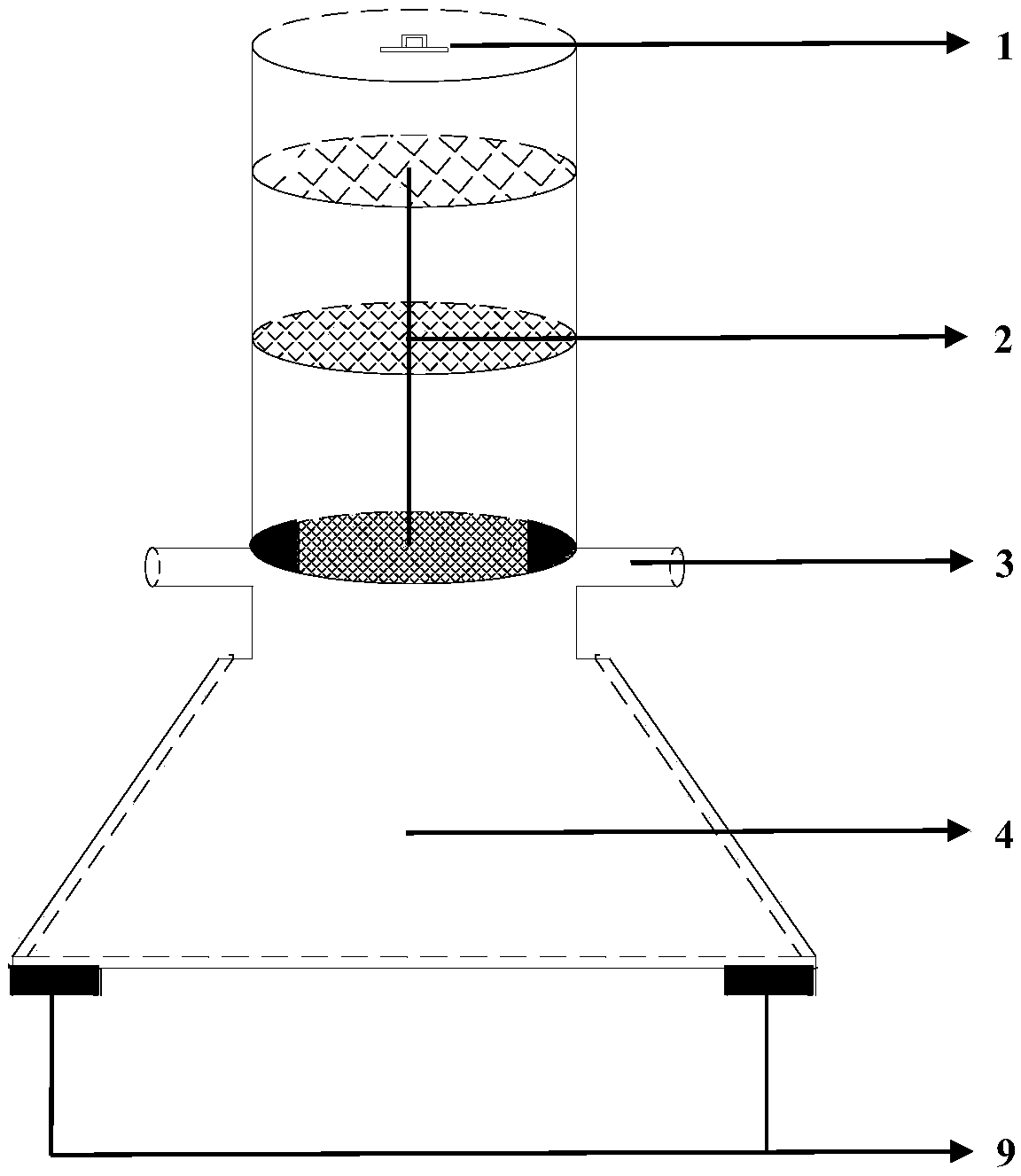

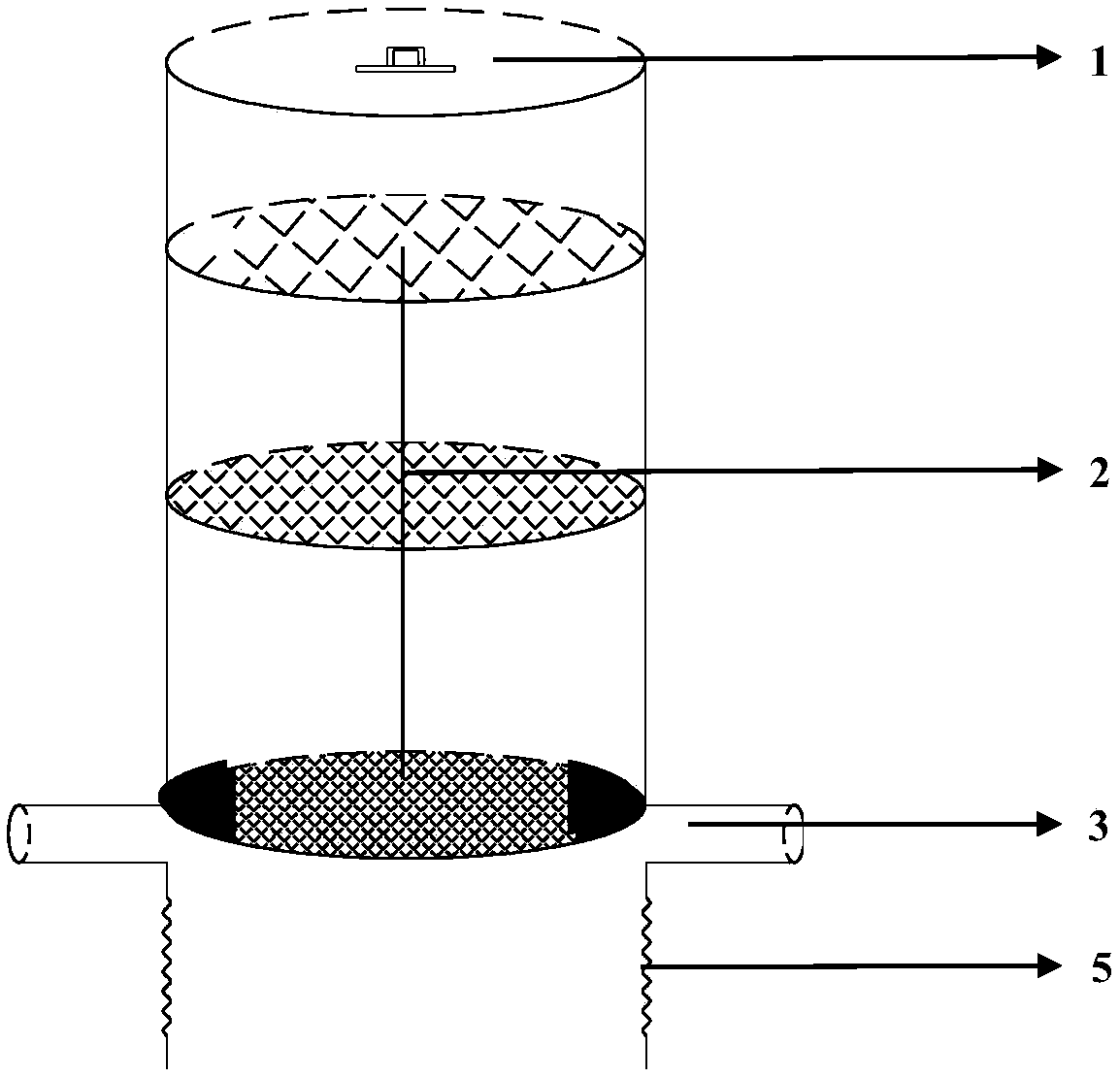

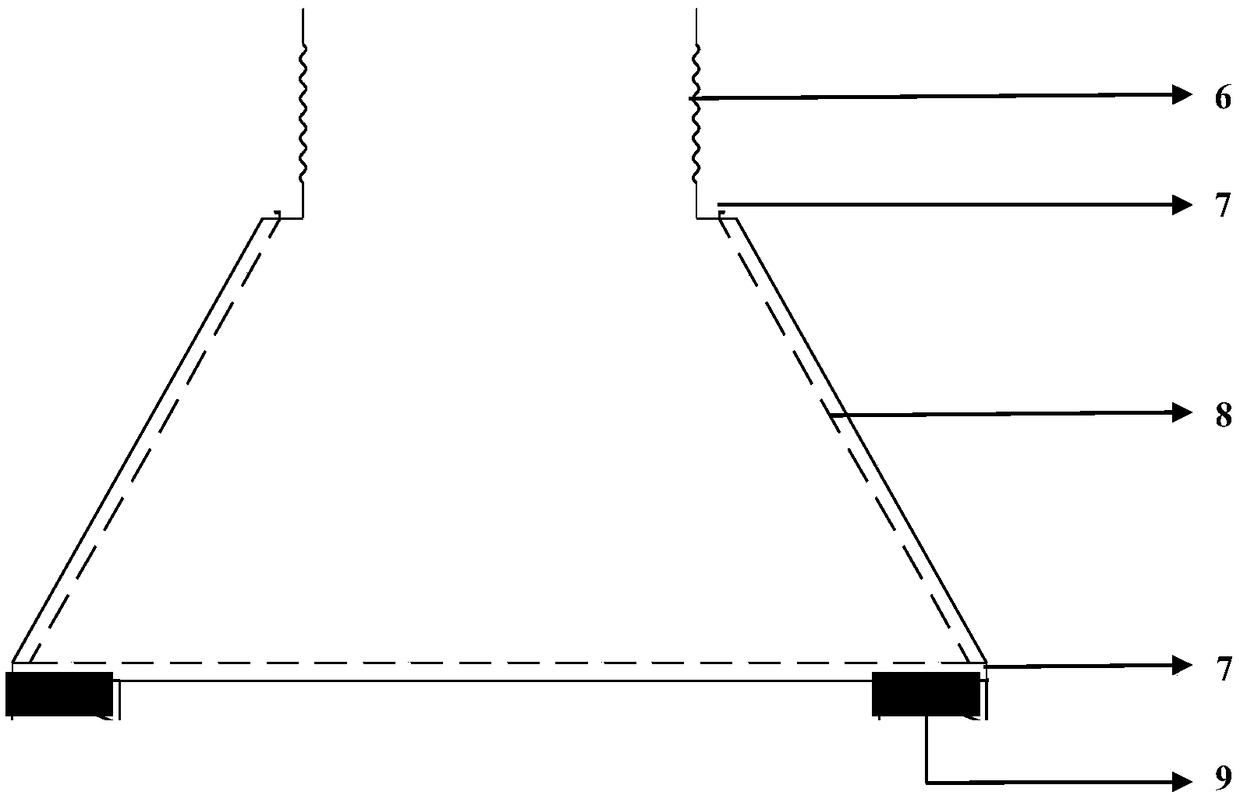

[0024] see figure 1 as well as figure 2 , the present invention provides a rapid dehydration and curing device for river silt, comprising an upper screening and curing device and a lower storage and drying device 4 connected to the upper screening and curing device; the upper screening and curing device includes a filter cartridge; the filter cartridge is a hollow cylinder body structure; the filter cartridge includes a feed port and a discharge port; the inside of the filter cartridge is provided with a filter screen 2; the side wall of the filter cartridge is provided with a ventilation hole 3 that communicates with the inside of the filter cartridge; The discharge port is connected; the discharge port is connected with the lower storage and drying device 4 .

[0025] The filter screen 2 adopted in the present invention is a multi-stage filter screen, comprising an upper filter screen, a middle filter screen and a lower filter screen from top to bottom; the mesh aperture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com