Sludge treatment system and working method thereof

A sludge treatment and sludge technology, applied in dehydration/drying/concentration sludge treatment, separation methods, chemical instruments and methods, etc., can solve the problems of increasing input costs, low drying efficiency, and no impurity filtering function, etc. To achieve the effects of reasonable working methods, saving input costs, and facilitating large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

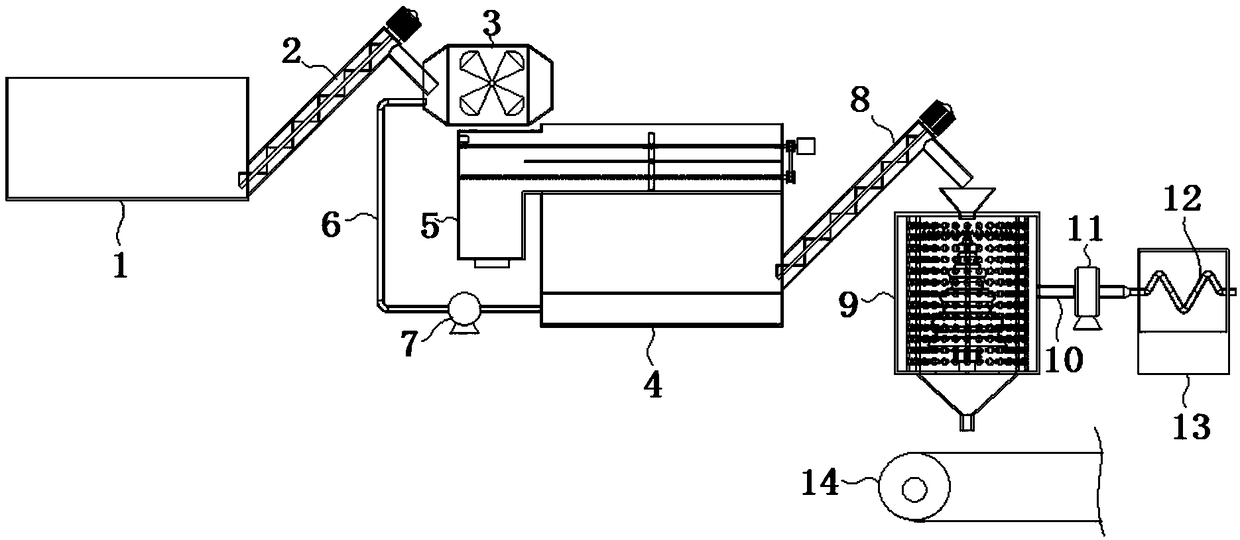

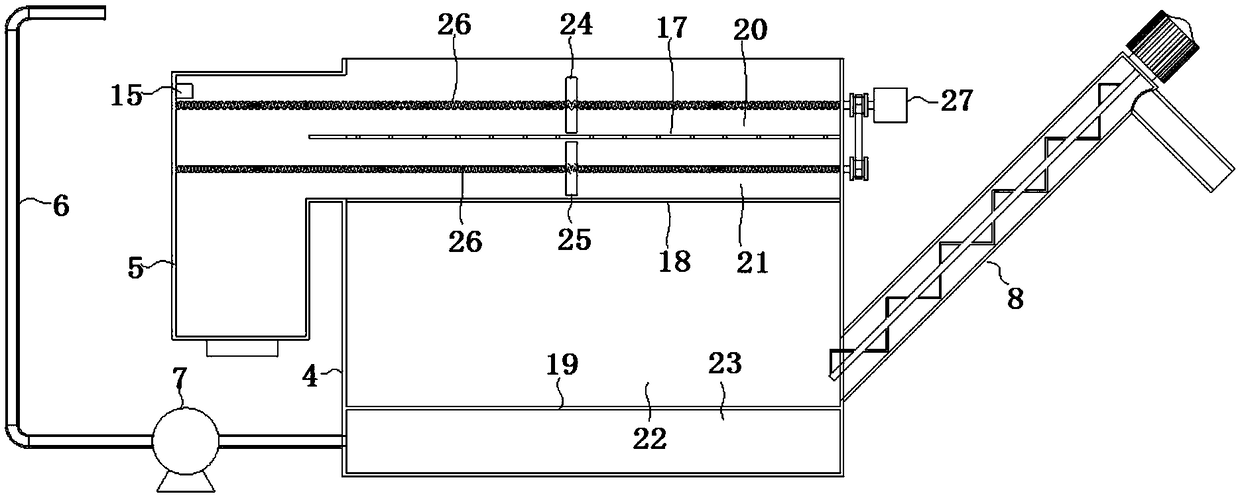

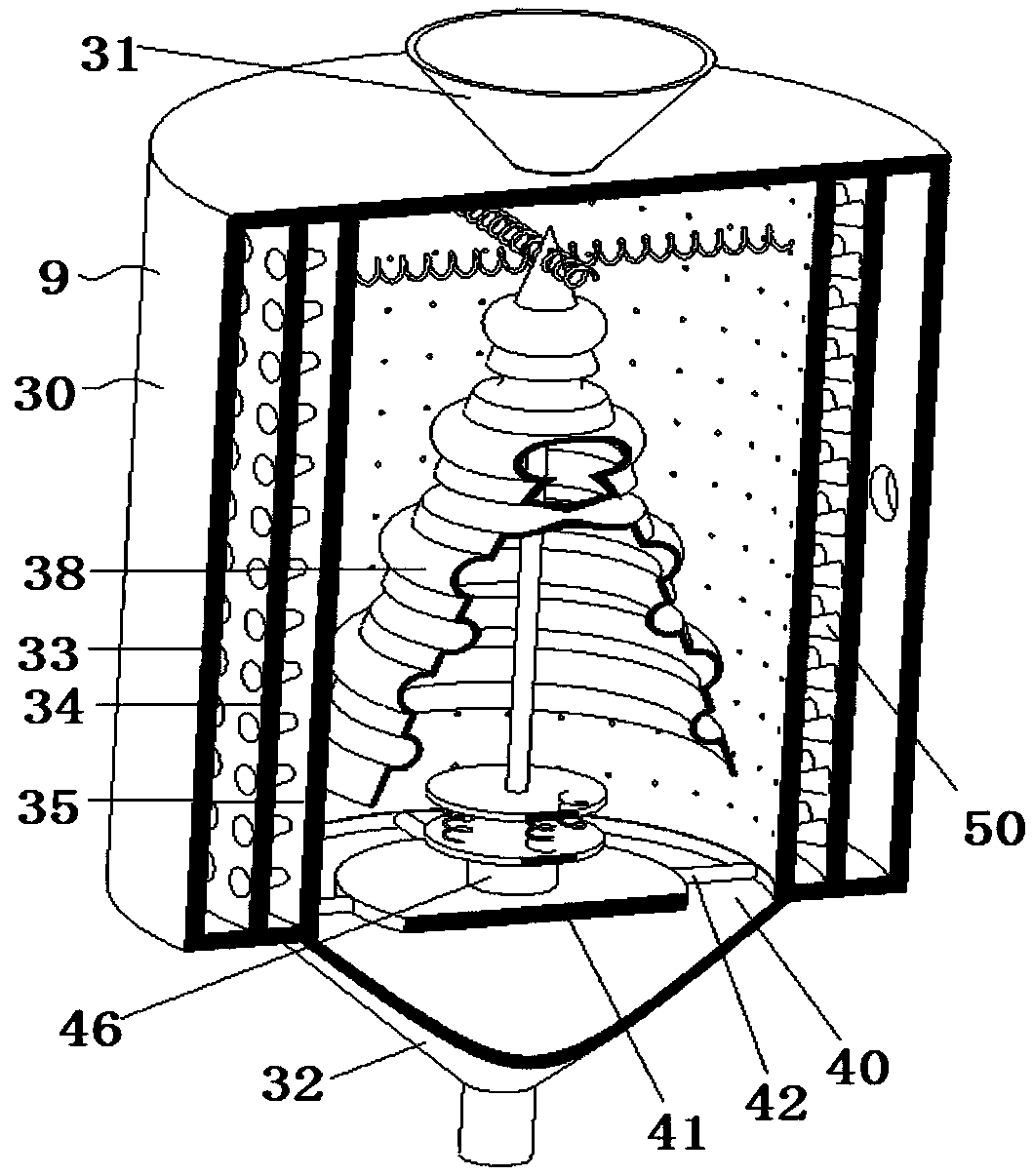

[0038] as attached figure 1 , a sludge treatment system, including a raw sludge storage tank 1, a first screw conveyor 2, a sludge dilution mixer 3, a sludge filtration seepage tank 4, a second screw conveyor 8, and a sludge air-drying box 9; The original sludge storage tank 1 is used to store the original sludge, and it is formed by pouring cement concrete outside the reinforced frame; the first screw conveyor 2 is located between the original sludge storage tank 1 and the sludge dilution mixer 3, which can The original sludge at the bottom of the original sludge storage tank 1 is transported to the sludge dilution mixer 3; the sludge filtration seepage tank 4 is located at the sludge output end of the sludge dilution mixer 3, and the side of the sludge filtration seepage tank 4 An impurity recovery box 5 communicating with the interior is provided, and the sludge fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com