A water shutoff agent for oil wells with bottom water reservoirs

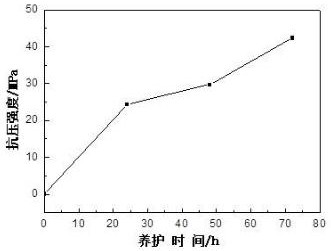

A technology of bottom water reservoirs and water blocking agents, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low formation cementation strength, high water outlet strength, easy shrinkage, etc., and achieve controllable thickening time , simple preparation, high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

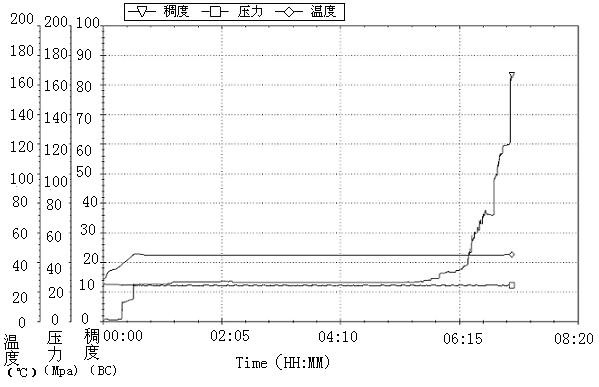

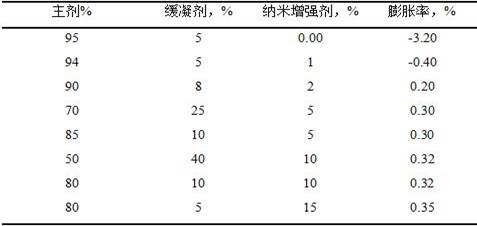

[0021] A water plugging agent for oil wells with bottom water reservoirs, which is made by mixing the following components according to weight percentage: 50%-98% of the main agent, 1%-30% of the nano-enhancer, and 1%-30% of the retarder 20%. The main agent is G-grade cement or ultra-fine cement, and the particle size range of G-grade cement or ultra-fine cement is 0.2µm-20µm; the nano-reinforcing agent is hydrophilic nano-silica and lipophilic nano-silica It is a mixture of 4:1-1:4 by mass; the retarder is larch sulfonated tannin extract, and the main component of larch sulfonated tannin extract is sulfonated products of tannin and non-tannin; the nano-enhanced The particle size of the agent is less than 50nm.

[0022] The preparation method of the water plugging agent for oil wells with bottom water reservoirs is as follows: adding a main agent with a weight percentage of 50%-98% in a kneader, and then adding a nano-enhancement agent with a weight percentage of 1%-30% and a...

Embodiment 2

[0028] A water shutoff agent for oil wells in bottom water reservoirs, which is prepared by mixing the following components according to the weight percentage: 50% of the main agent, 10% of the nano-enhancer, and 40% of the retarder. The main agent is G-grade cement with a particle size of 10 μm; the nano-reinforcing agent is a mixture of hydrophilic nano-silica and lipophilic nano-silica in a mass ratio of 1:1; the retarder is fallen leaves Pine sulfonated tannin extract and larch sulfonated tannin extract are mainly composed of tannin and non-tannin sulfonated products; the particle diameter of the nano-reinforcing agent is 50nm.

[0029] The preparation method of the water plugging agent for oil wells in bottom water reservoirs is as follows: adding 50% by weight of the main agent into the kneader, and then adding 10% by weight of nano-reinforcing agent and 40% by weight of retarder , stir for more than 30 minutes until the three are evenly mixed, stop stirring, and get the...

Embodiment 3

[0031] A water shutoff agent for oil wells in bottom water reservoirs, which is prepared by mixing the following components according to the weight percentage: 50% of the main agent, 10% of the nano-enhancer, and 40% of the retarder. The main agent is ultra-fine cement with a particle size of 15 μm; the nano-reinforcing agent is a mixture of hydrophilic nano-silica and lipophilic nano-silica in a mass ratio of 1:1; the retarder is fallen leaves Pine sulfonated tannin extract and larch sulfonated tannin extract are mainly composed of tannin and non-tannin sulfonated products; the particle size of the nano-reinforcing agent is 40nm.

[0032] The preparation method of the water plugging agent for oil wells in bottom water reservoirs is as follows: adding 50% by weight of the main agent into the kneader, and then adding 10% by weight of nano-reinforcing agent and 40% by weight of retarder , stir for more than 30 minutes until the three are evenly mixed, stop stirring, and get the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com