A special conductive fiber material with permanent antistatic and melt direct spinning

A conductive fiber, antistatic technology, applied in fiber processing, conductive/antistatic filament manufacturing, textile and papermaking, etc., can solve the problem of inability to directly add antistatic agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

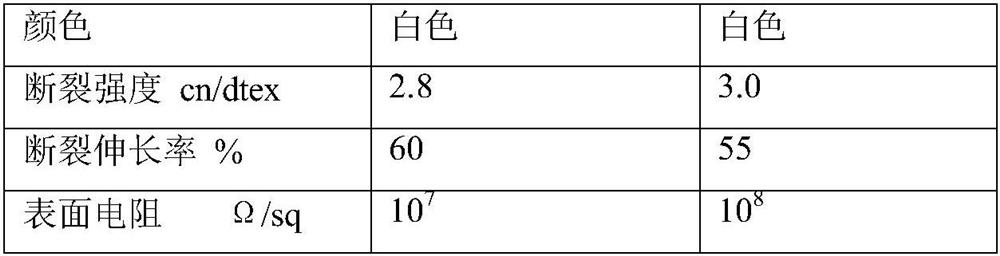

Examples

Embodiment 1

[0070] Preparation of conductive fiber special material:

[0071] 100g of nylon 6 / 66 prepolymer with a molecular weight of 1500-2500,

[0072] Dibasic acid-terminated polyether polyol 85g,

[0073] Ethoxylauramide 2g,

[0074] Sodium dodecylbenzenesulfonate 2.6g,

[0075] Lithium bisoxalate borate 0.5g,

[0076] 15g of deionized water.

[0077] Put the above materials into the reaction kettle and react for 20 hours at 270°C with a stirring speed of 50 rpm to prepare the special material for cable sheathing.

[0078] Among them, the preparation method of lithium bisoxalate borate is as follows: using water as the medium, mixing lithium hydroxide with oxalic acid and boric acid, reacting at 60°C, evaporating and crystallizing.

[0079] The multi-component nylon prepolymer comprises the following raw materials by mass percentage:

[0080] Nylon 66 salt 10%, nylon 610 salt 20%,

[0081] Dodecanoic Acid 15%,

[0082] Dodecyl diamine 15%,

[0083] Antioxidant 0.2%,

[0084...

Embodiment 2

[0094] Preparation of conductive fiber special material:

[0095] 100g of nylon 6 / 66 prepolymer with a molecular weight of 1500-2500,

[0096] Dibasic acid-terminated polyester polyol 85g,

[0097] Ethoxylauramide 2g,

[0098] Sodium octadecylbenzenesulfonate 2.6g,

[0099] Lithium bisoxalate borate 0.5g,

[0100] 15g of deionized water.

[0101] Among them, the preparation method of lithium bisoxalate borate is: using water as the medium, mixing lithium hydroxide with oxalic acid and boric acid, reacting at 40°C, evaporating and crystallizing.

[0102] Multi-component nylon prepolymer includes the following raw materials by mass percentage:

[0103] Nylon 66 salt 10%, Nylon 610 salt 25%,

[0104] p-toluic acid 20%,

[0105] p-Phenylenediamine 20%,

[0106] Antioxidant 0.5%,

[0107] Orthophosphate 0.05%,

[0108] water balance.

[0109] The preparation method of multi-component nylon prepolymer is as follows: add the raw materials into the reaction kettle according...

Embodiment 3

[0117] Preparation of conductive fiber special material:

[0118] 110g of nylon 6 / 66 prepolymer with a molecular weight of 1500-2500,

[0119] Dibasic acid-terminated polyether polyol 80g,

[0120] Ethoxylauramide 2g,

[0121] Sodium octadecylbenzenesulfonate 2.6g,

[0122] Lithium bisoxalate borate 0.5g,

[0123] 15g of deionized water.

[0124] Among them, the preparation method of lithium bisoxalate borate is as follows: using water as the medium, mixing lithium hydroxide with oxalic acid and boric acid, reacting at 80°C, evaporating and crystallizing.

[0125] The multi-component nylon prepolymer comprises the following raw materials by mass percentage:

[0126] Nylon 66 salt 20%, Nylon 610 salt 10%,

[0127] Adipic acid 5%, suberic acid 5%,

[0128] Hexamethylenediamine 5%, octanediamine 5%,

[0129] Antioxidant 0.1%,

[0130] Orthophosphate 0.02%,

[0131] water balance.

[0132] The preparation method of the multi-component nylon prepolymer is as follows: add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com