A kind of hydrophobic oleophobic antistatic PVC composite film and preparation method thereof

A composite film, antistatic technology, applied in coating, printing, printing devices, etc., can solve the problems of affecting surface finish, poor stability of composite system, interface layered deposition and precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An anti-fouling and anti-static PVC composite film: an anti-fouling and self-cleaning agent is screen-printed on the surface of the anti-static PVC composite film;

[0024] The antistatic PVC composite film includes the following components in weight percent: 65% polyvinyl chloride, 10% polytetrafluoroethylene, 12% acrylic monomer, 6% hydroxylated graphene, 4% aminated graphene, chlorinated 0.1% of sulfoxide, 1.8% of hyperbranched polystyrene, 1% of polypyrrole, 0.1% of fatty acid polyoxyethylene ether ester; the antifouling self-cleaning agent includes the following components in weight percentage: nano TiO 2 Sol 55%, nano silver powder 5%, lotus leaf hydrophobic agent 10%, perfluorooctyl triethoxysilane 10%, perfluoroalkyl ethyl acrylate 20%; the nano TiO 2 Nano TiO in Sol 2 The content is 10%.

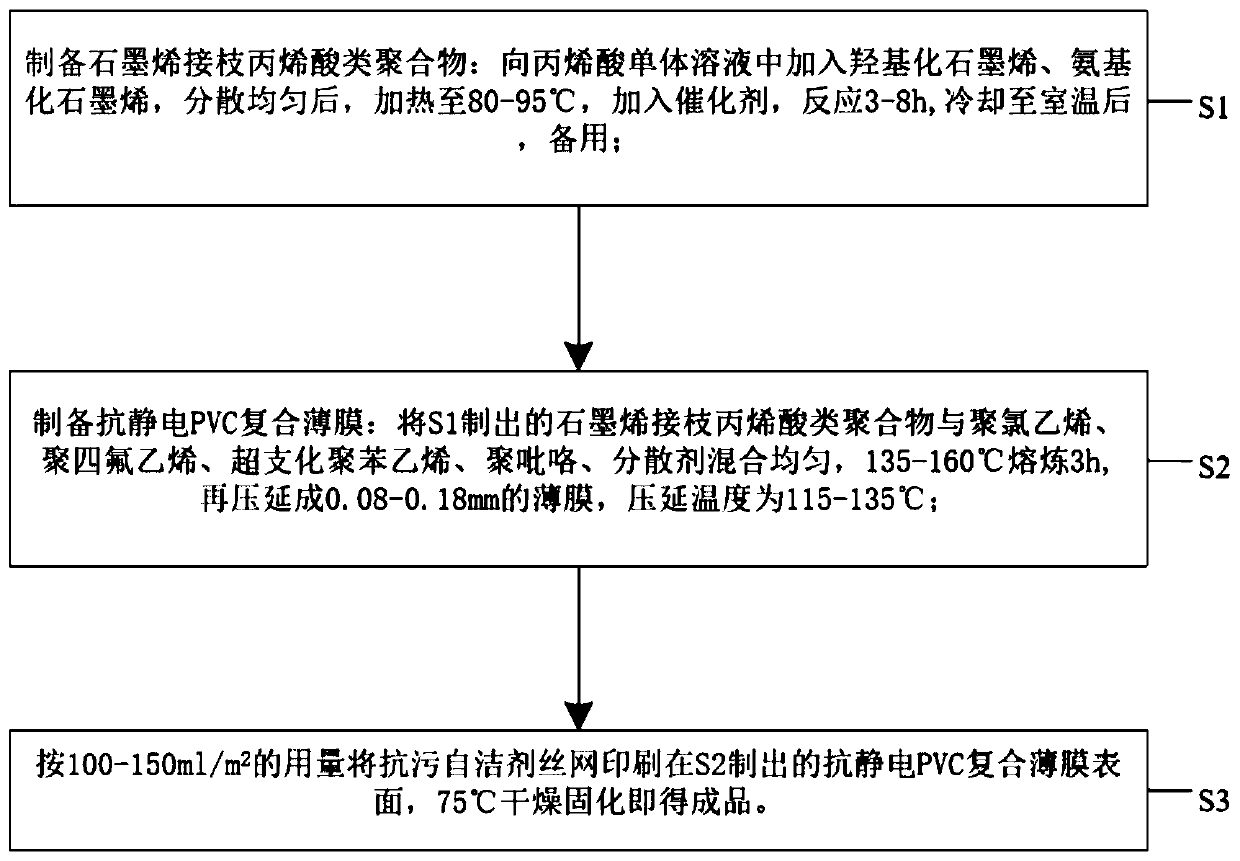

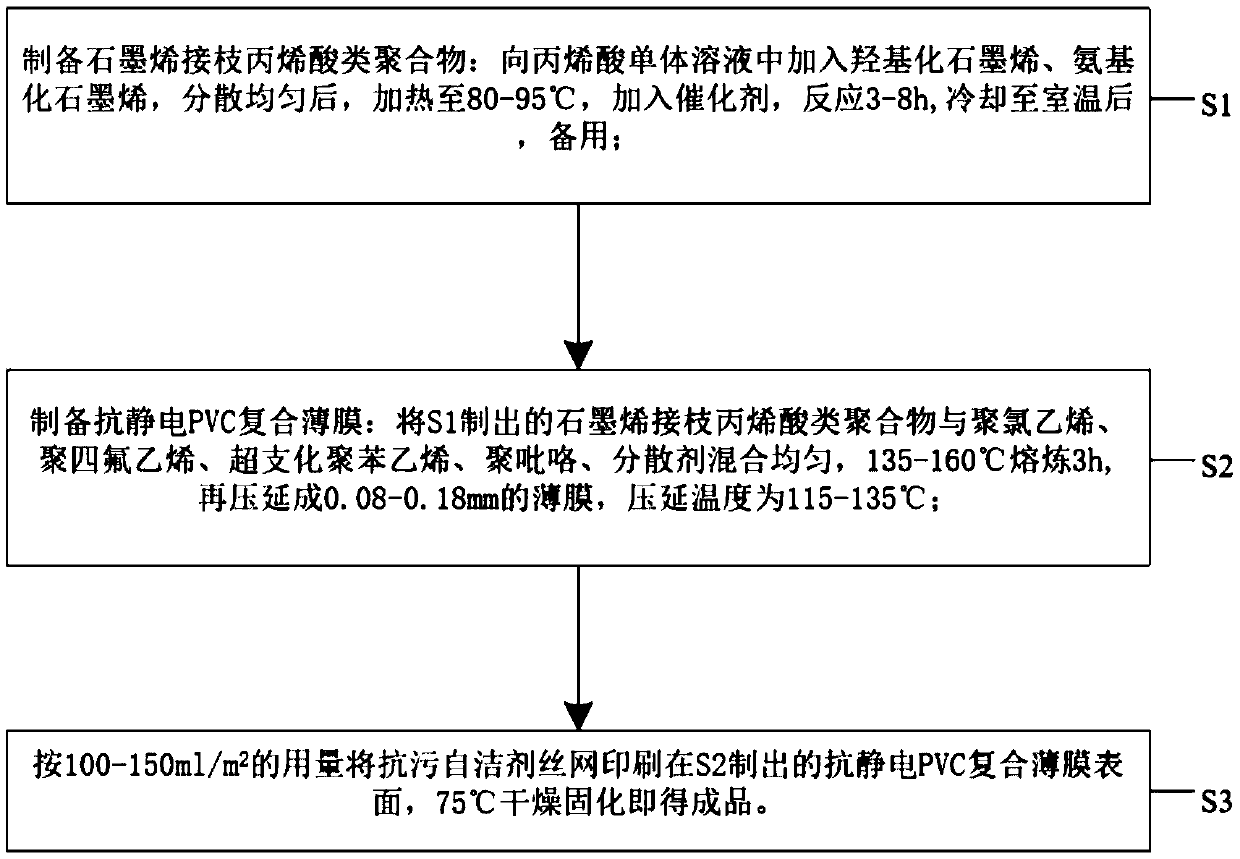

[0025] The preparation method of the antifouling and antistatic PVC composite film comprises the following steps:

[0026] S1: Preparation of graphene-grafted acrylic poly...

Embodiment 2

[0030] An anti-fouling and anti-static PVC composite film: an anti-fouling and self-cleaning agent is screen-printed on the surface of the anti-static PVC composite film;

[0031] The antistatic PVC composite film includes the following components in weight percent: 45-65% polyvinyl chloride, 12% polytetrafluoroethylene, 15% acrylic monomer, 8% hydroxylated graphene, 5% aminated graphene, Thionyl chloride 0.2%, hyperbranched polystyrene 3%, polypyrrole 1.5%, fatty acid polyoxyethylene ether ester 0.3%; the anti-fouling self-cleaning agent includes the following components in weight percentage: nano TiO 2 Sol 42%, nano silver powder 8%, lotus leaf hydrophobic agent 12.5%, perfluorooctyl triethoxysilane 12.5%, perfluoroalkyl ethyl acrylate 25%; the nano TiO 2 Nano TiO in Sol 2 The content is 12.5%.

[0032] The preparation method of the antifouling and antistatic PVC composite film comprises the following steps:

[0033] S1: Preparation of graphene-grafted acrylic polymer: Ad...

Embodiment 3

[0037] An anti-fouling and anti-static PVC composite film: an anti-fouling and self-cleaning agent is screen-printed on the surface of the anti-static PVC composite film;

[0038]The antistatic PVC composite film includes the following components in weight percent: 45% polyvinyl chloride, 14% polytetrafluoroethylene, 18% acrylic monomer, 10% hydroxylated graphene, 6% aminated graphene, chlorinated 0.5% of sulfoxide, 4% of hyperbranched polystyrene, 2% of polypyrrole, 0.5% of polyvinyl alcohol; the antifouling self-cleaning agent includes the following components in weight percentage: nano TiO 2 Sol 30%, nano silver powder 10%, lotus leaf hydrophobic agent 15%, perfluorooctyl triethoxysilane 15%, perfluoroalkyl ethyl acrylate 30%; the nano TiO 2 Nano-TiO in Sol 2 The content is 15%.

[0039] The preparation method of the antifouling and antistatic PVC composite film comprises the following steps:

[0040] S1: Preparation of graphene-grafted acrylic polymer: Add hydroxylated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com