A large-diameter steel cage skeleton forming machine and method

A steel cage, large diameter technology, applied in the processing of building materials, construction, infrastructure engineering and other directions, can solve the problems of poor practicability, poor stability, complex structure, etc., to avoid processing difficulties, small footprint, Quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

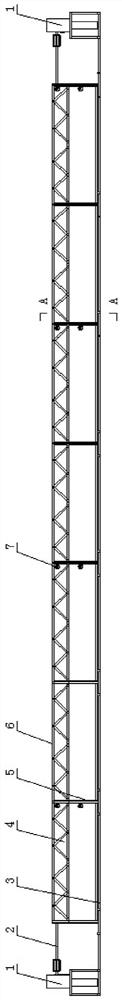

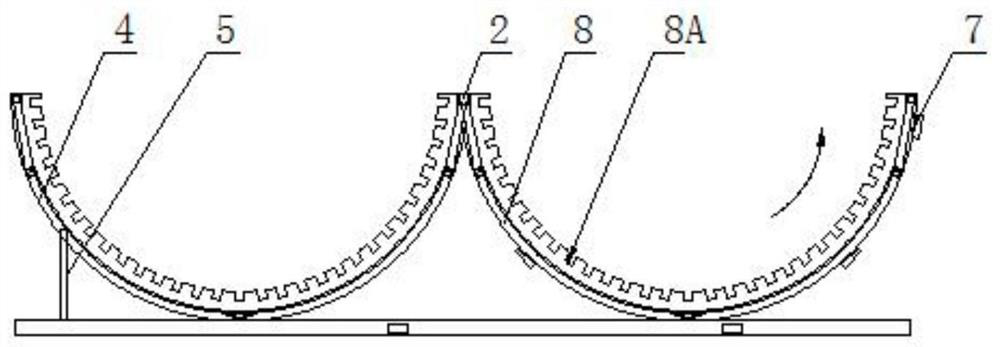

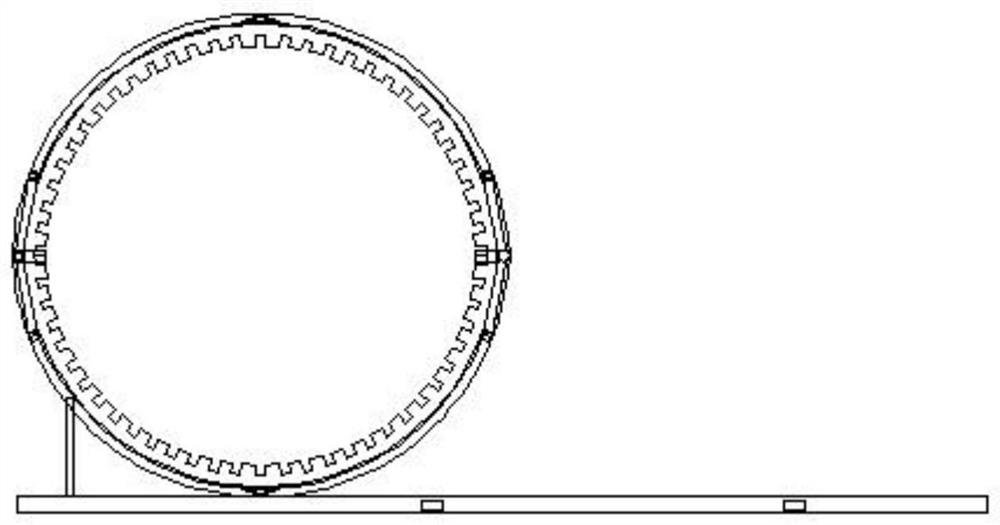

[0035] A large-diameter steel cage skeleton forming machine, such as Figure 1 to Figure 3 As shown, it includes a base 3, a semicircular fixed member 4 and a semicircular rotating member 8. A plurality of semicircular fixed members are fixed in parallel and spaced longitudinally on the base, and the two ends of the semicircular fixed member are connected to the Together, there are eight semicircular fixed members in this embodiment, the bottom of the semicircular fixed member is connected to the base, and one side of each semicircular fixed member is respectively rotated and connected to the semicircular rotating member through the rotating shaft 2, and the two semicircular rotating members The ends are also equipped with horizontally arranged trusses, and the two ends of the rotating shaft are respectively connected to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com