Concrete curing system of high-rise structure and construction method thereof

A maintenance system and high-rise structure technology, which is applied in the direction of building structure, construction, and building materials, can solve the problems of inconvenient maintenance of high-rise structure concrete, waste of water resources, and complicated disassembly and assembly procedures, etc., to improve the maintenance effect , saving water resources and speeding up maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

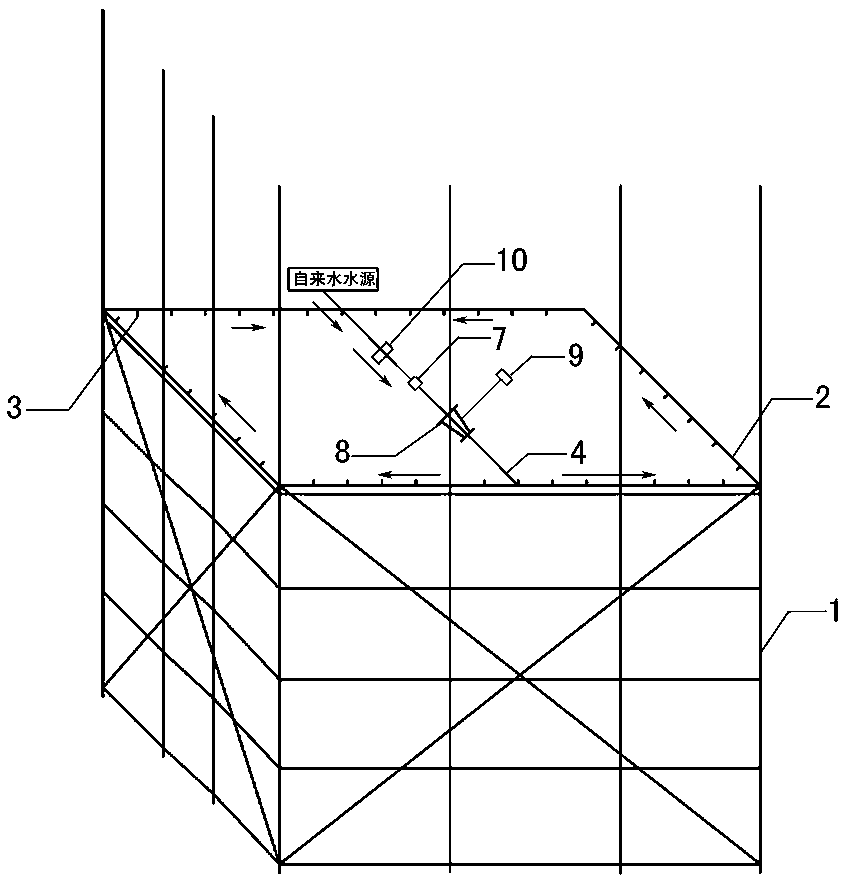

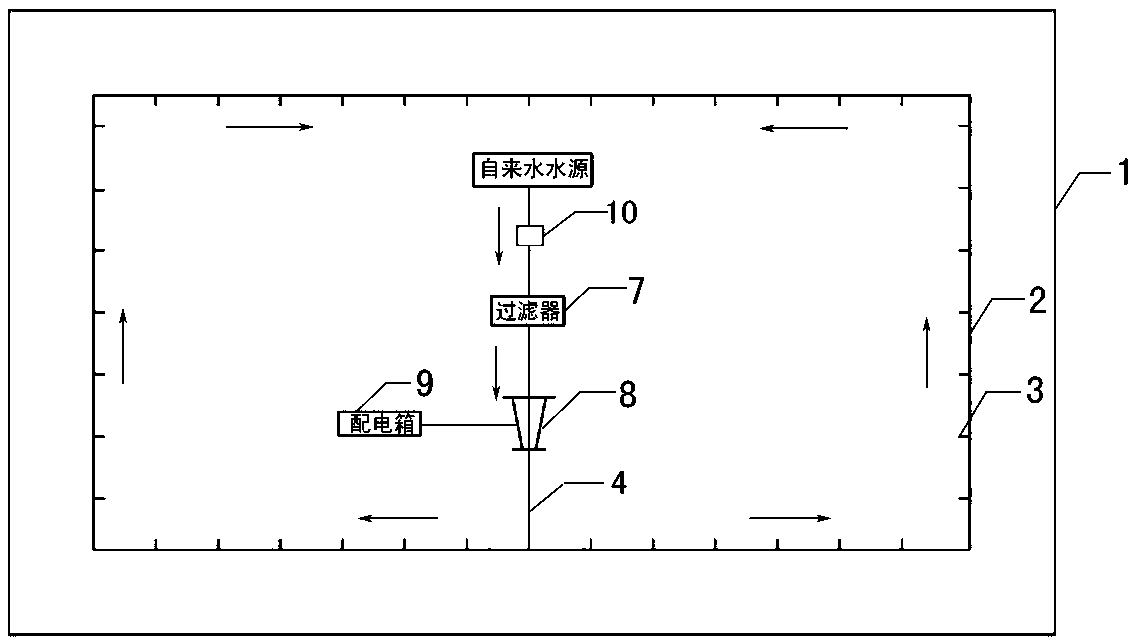

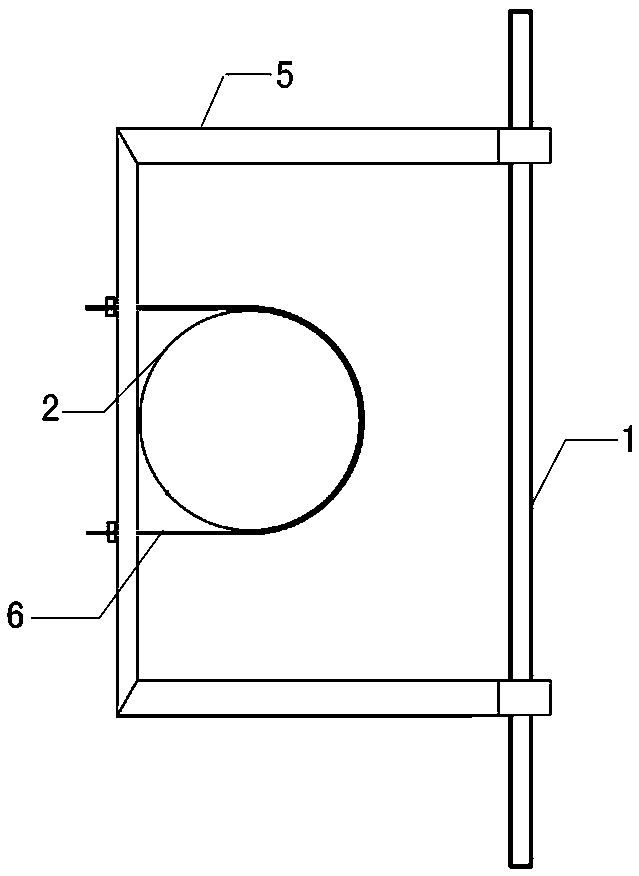

[0037] Examples see figure 1 and figure 2 As shown, a high-rise structural concrete maintenance system is mainly used for the maintenance of high-rise facade structural concrete, including a hydraulic climbing frame 1 arranged around the concrete to be maintained in the structure, and the inner side of the upper end of the hydraulic climbing frame is detachably connected by a connecting component There is a spray pipeline 2, which is arranged horizontally and is in a closed ring shape. On the side facing the concrete to be cured, the spray pipeline 2 is connected with rotatable spray pipes at uniform intervals along the ring direction through the first three-way joint. The sprinkler head 3, the spraying pipeline 2 is connected with the water inlet pipeline 4 through the second three-way joint, and the mechanical timing switch 10 is arranged on the water inlet pipeline, and the mechanical timing switch 10 is set according to the concrete maintenance situation in the concrete c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com