Electric boiler capable of rapidly descaling

An electric boiler and fast technology, applied in the field of boilers, can solve the problems of high production cost, difficult cleaning of heating pipes, complicated processing technology of heating pipes, etc., and achieve the effects of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

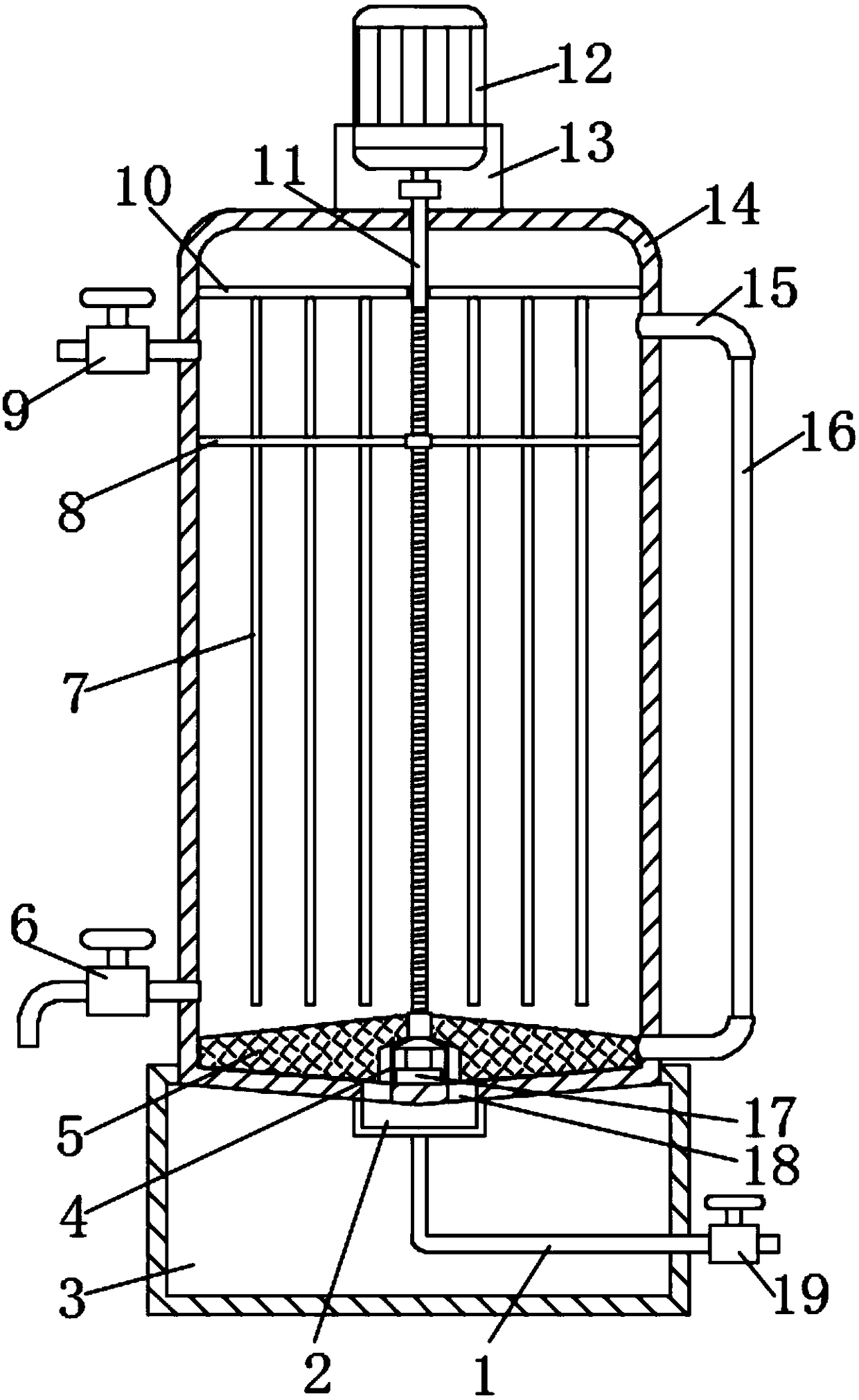

[0026] Embodiment one, with reference to figure 1 , an electric boiler capable of quick descaling, comprising a base 3, a faucet 6, a water inlet valve 9, a boiler body 14, an elbow 15 and a liquid level tube 16, the upper part of the base 3 is provided with a boiler body 14, the boiler body 14 The outer wall is connected with the water inlet valve 9 and the faucet 6 sequentially from top to bottom. The tap water is injected into the boiler body 14 through the water inlet valve 9, and the tap water is taken out through the faucet 6. The outer wall of the boiler body 14 is connected through the elbow 15 at the upper and lower positions. There is a vertical liquid level pipe 16 through which the user can connect to the water level inside the boiler body 14. The top of the boiler body 14 is fixed with a motor 12 through a motor base 13, and the motor 12 is connected to the boiler body 14 through a coupling. The internal lead screw 11 is connected by transmission. The inner bottom...

Embodiment 2

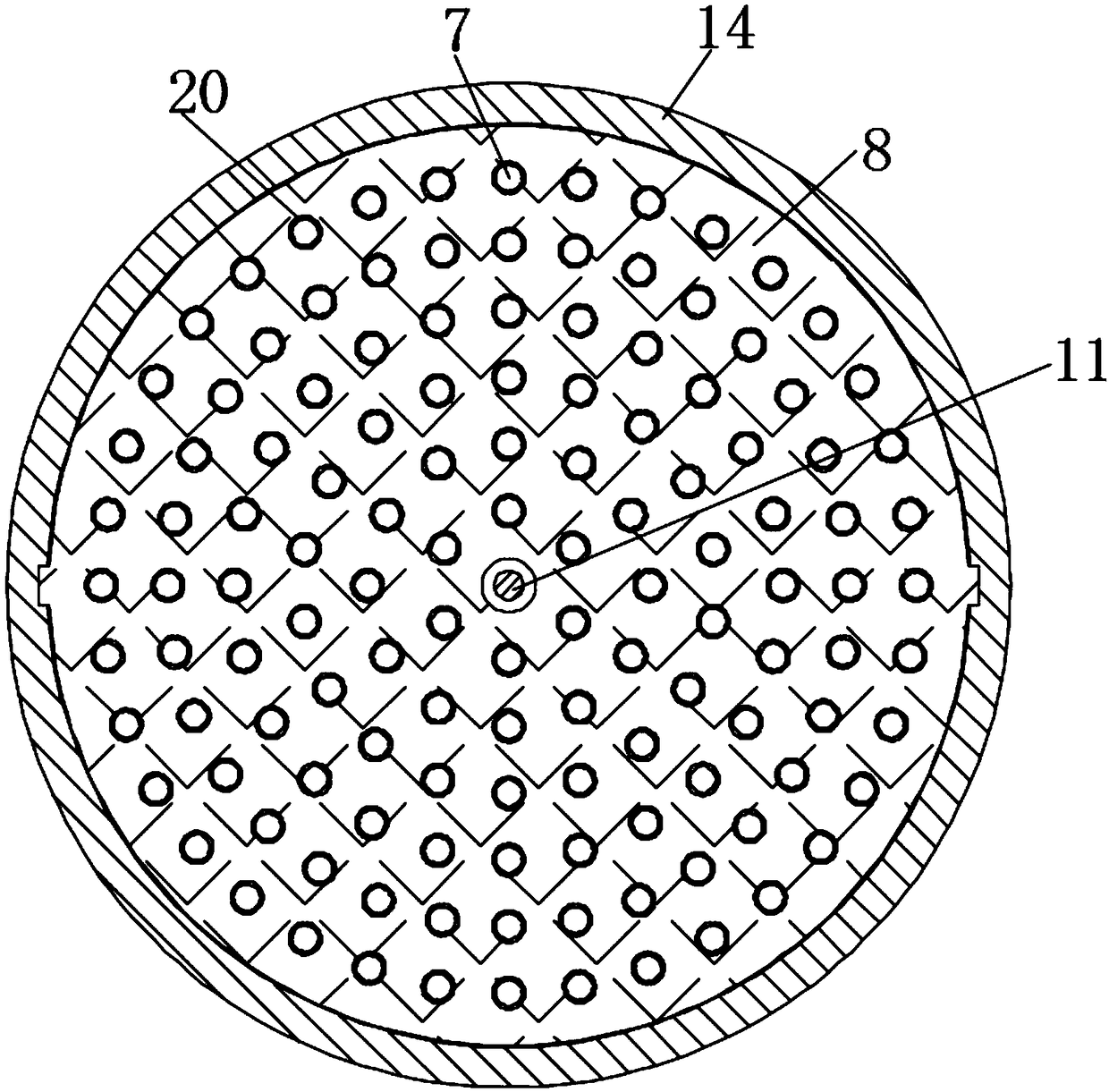

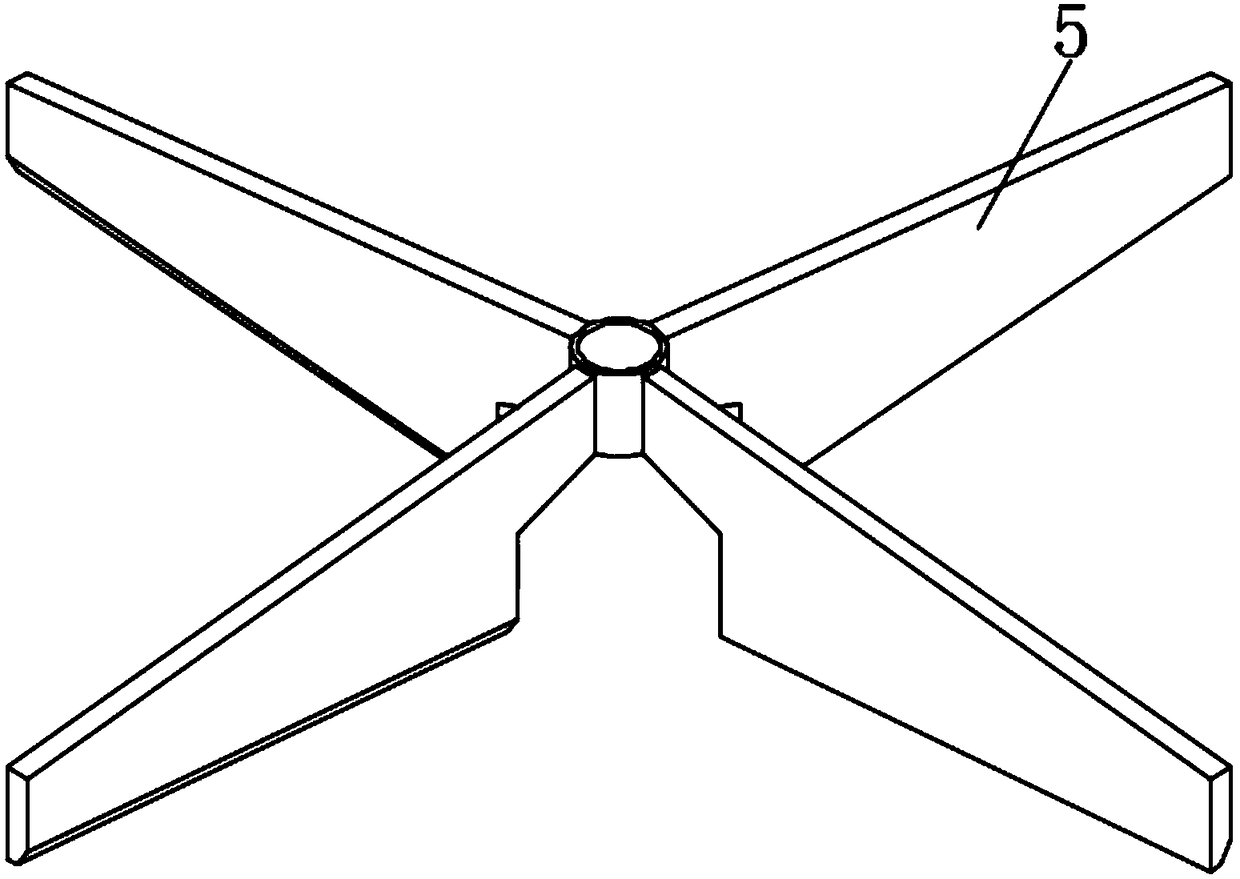

[0027] Embodiment two, refer to Figure 1-5 , the outer screw 11 is screwed with a disc scraper 8, and the disc scraper 8 is provided with a heating tube hole 21 at the position corresponding to the heating tube 7, and the inside of the heating tube hole 21 is embedded with a silicone sleeve 20. The silicone sleeve 20 can prevent the disc scraper 8 from causing abrasion to the outer wall of the heating tube 7, the bottom of the lead screw 11 is sleeved with a fan blade scraper 5, and the bottom end of the fan blade scraper 5 is in close contact with the inner bottom of the boiler body 14 In this way, when the motor 12 is working, the motor 12 drives the screw 11 to rotate. Since the screw 11 and the disc scraper 8 are screwed together, and the disc scraper 8 and the heating tube 7 are nested with each other, the disc scraper 8. When moving up and down, the scale on the inner wall of the boiler and the outer wall of the heating pipe 7 can be scraped off.

Embodiment 3

[0028] Embodiment three, refer to figure 1 A drain hole 18 is provided at the center of the inner bottom of the boiler body 14, and the bottom of the boiler body 14 corresponding to the position of the drain hole 18 is provided with a water collection cover 2, and the bottom of the water collection cover 2 passes through the water pipe 1 and the outer wall of the base 3. The sewage valve 19 is connected, so that when the scale inside the boiler body 14 is scraped off, liquid is injected into the boiler body 14 through the water inlet valve 9, and then the sewage valve 19 is opened, so that the scale accumulates in the water collecting cover 2 through the drain hole 18 , and then discharge outwards from the sewage valve 19 through the water pipe 1.

[0029] Working principle: first inject tap water into the boiler body 14 through the water inlet valve 9, and then heat the tap water inside the boiler body 14 through the heating tube 7. After the heating tube 7 is used for a peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com