A preloaded high-frequency vibration fatigue test device

A high-frequency vibration and fatigue test technology, which is applied in the direction of measuring devices, testing material strength by applying repetitive force/pulsation force, instruments, etc., can solve problems such as applied average stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

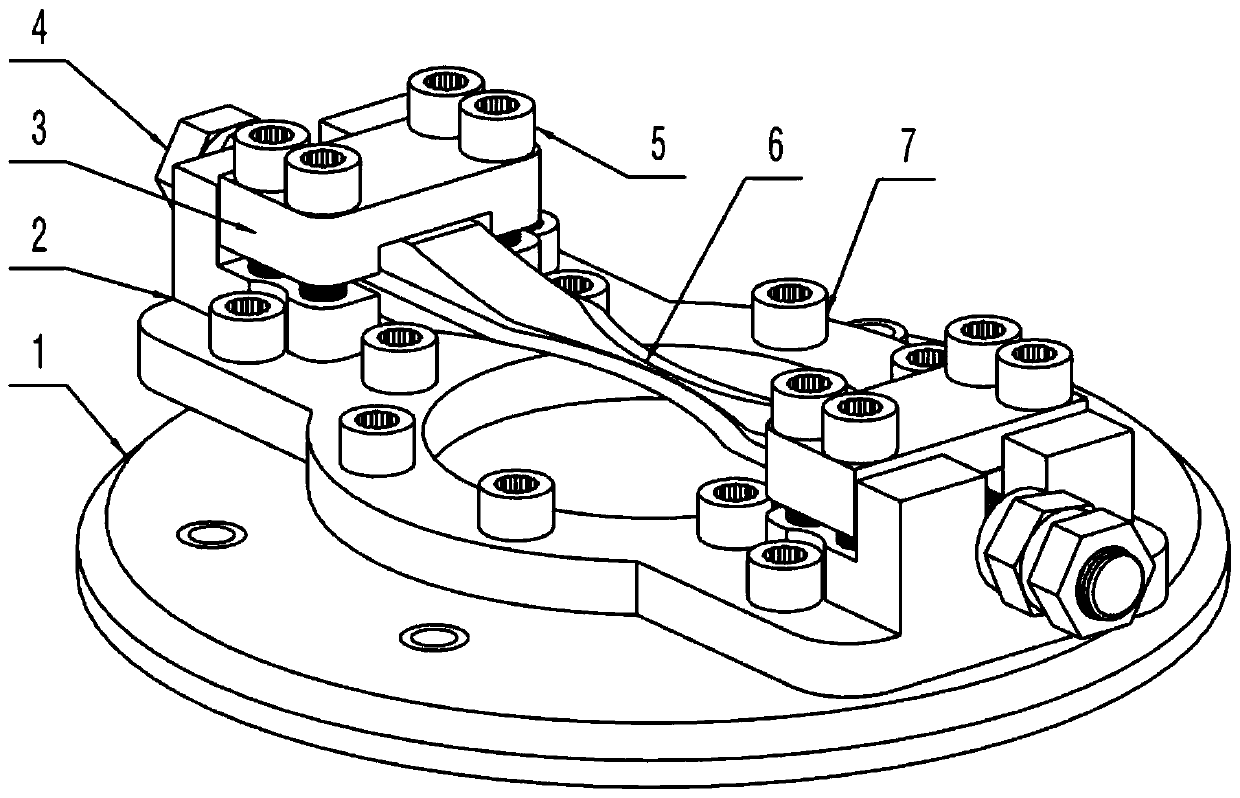

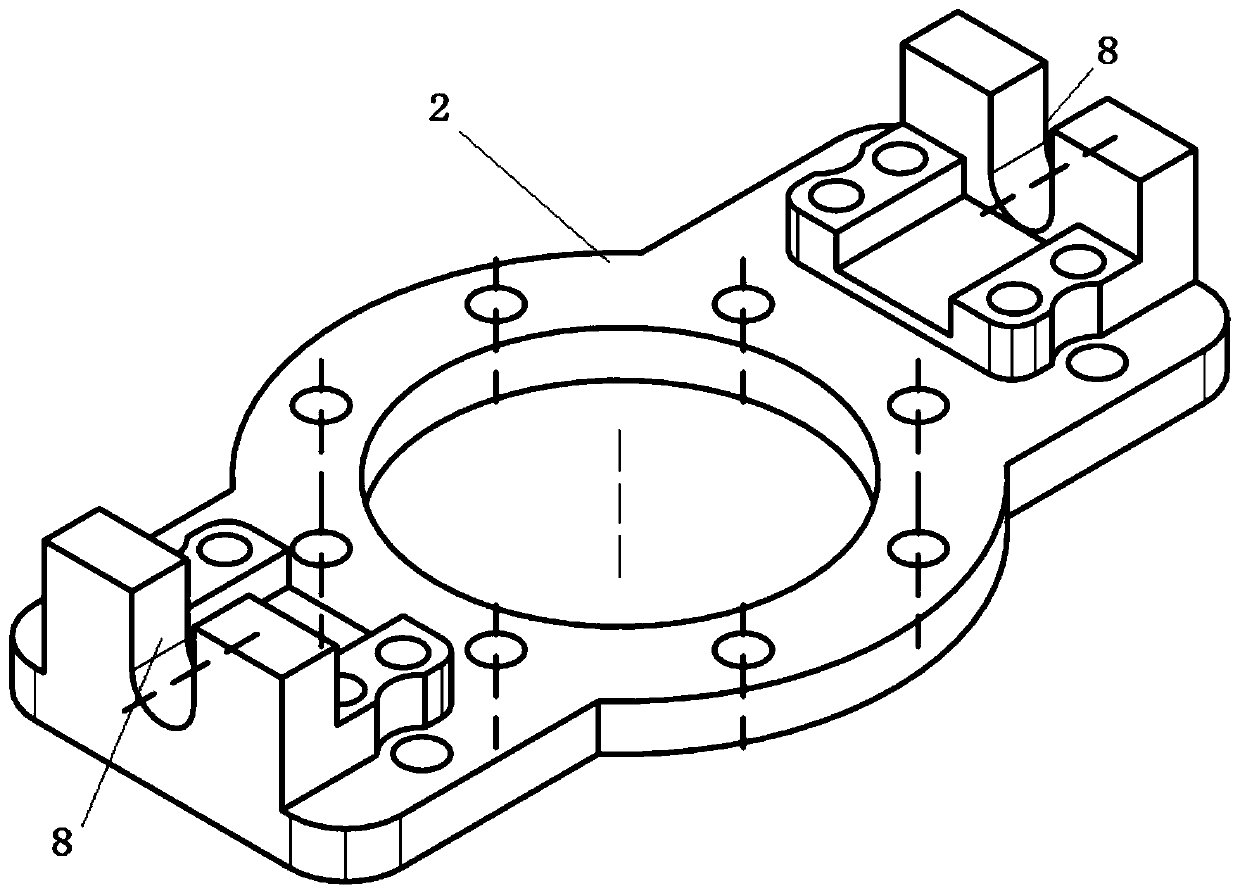

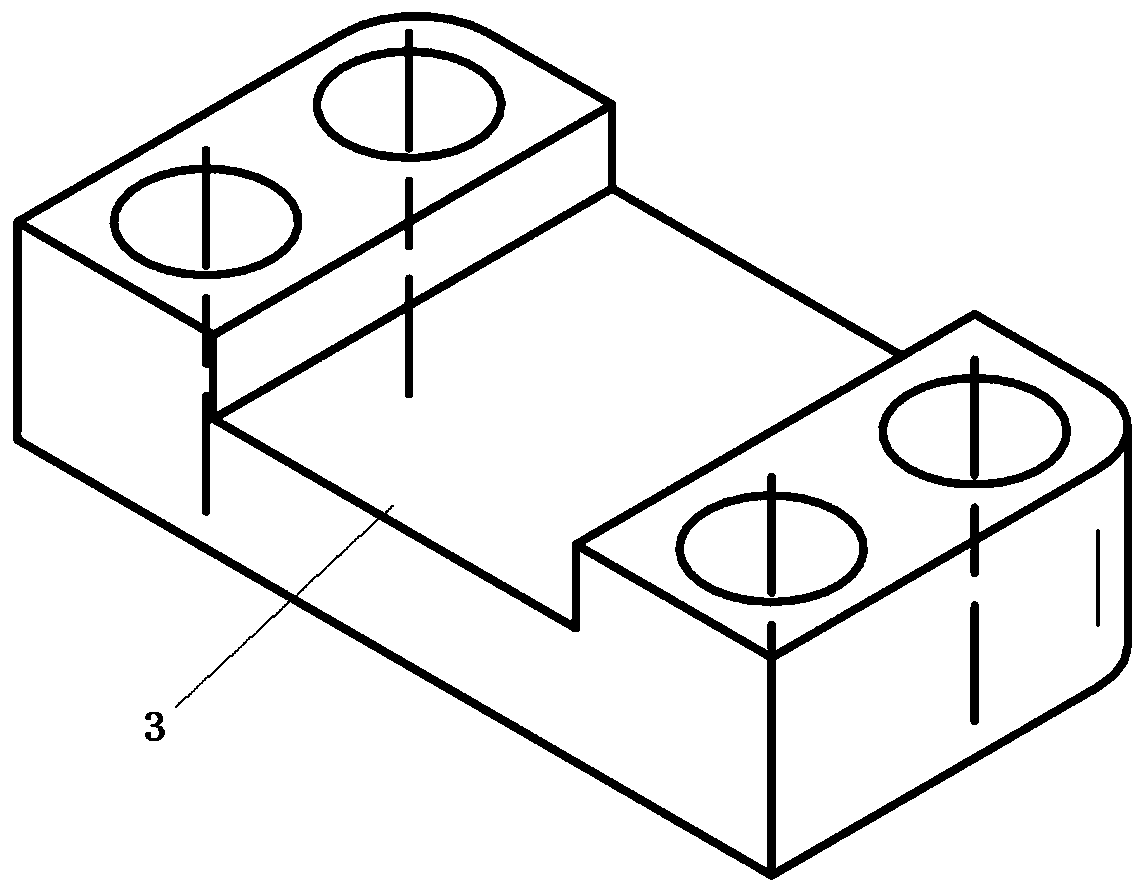

[0034] This embodiment is a four-point bending fatigue test fixture.

[0035] Such as Figure 1-6 As shown, a preload high-frequency vibration fatigue test device of the present invention includes a sample 6 and a clamp, and the sample 6 is strip-shaped, which includes a test section A in the middle, and a holding section B at both ends of the test section A. The ends of the two clamping sections B are each connected with a stud 9; the fixture includes a fixture base 2 and two clamping blocks 3, the fixture base 2 is installed on the connecting plate 1 of the electric vibrating table, and is passed through a plurality of second bolts 7 is fixed on the connection plate 1; two ends of the fixture base 2 are respectively provided with a slot 8, and the opening width of the slot 8 is smaller than the width of the clamping section B of the sample 6; the studs 9 at both ends of the sample 6 are respectively snapped into In the two draw-in grooves 8, nuts 4 are installed at the ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com