CIS (Contact Image Sensor) camera for circuit board and light source module

A light source module and circuit board technology, which is applied in the direction of using optical devices, optical testing for flaws/defects, and material analysis through optical means, which can solve the problem of affecting the judgment ability of circuit boards in taking pictures and affecting the binarization misjudgment of image processing , Take photos with uneven brightness and darkness, etc., to avoid misjudgment, improve consistency, and avoid mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

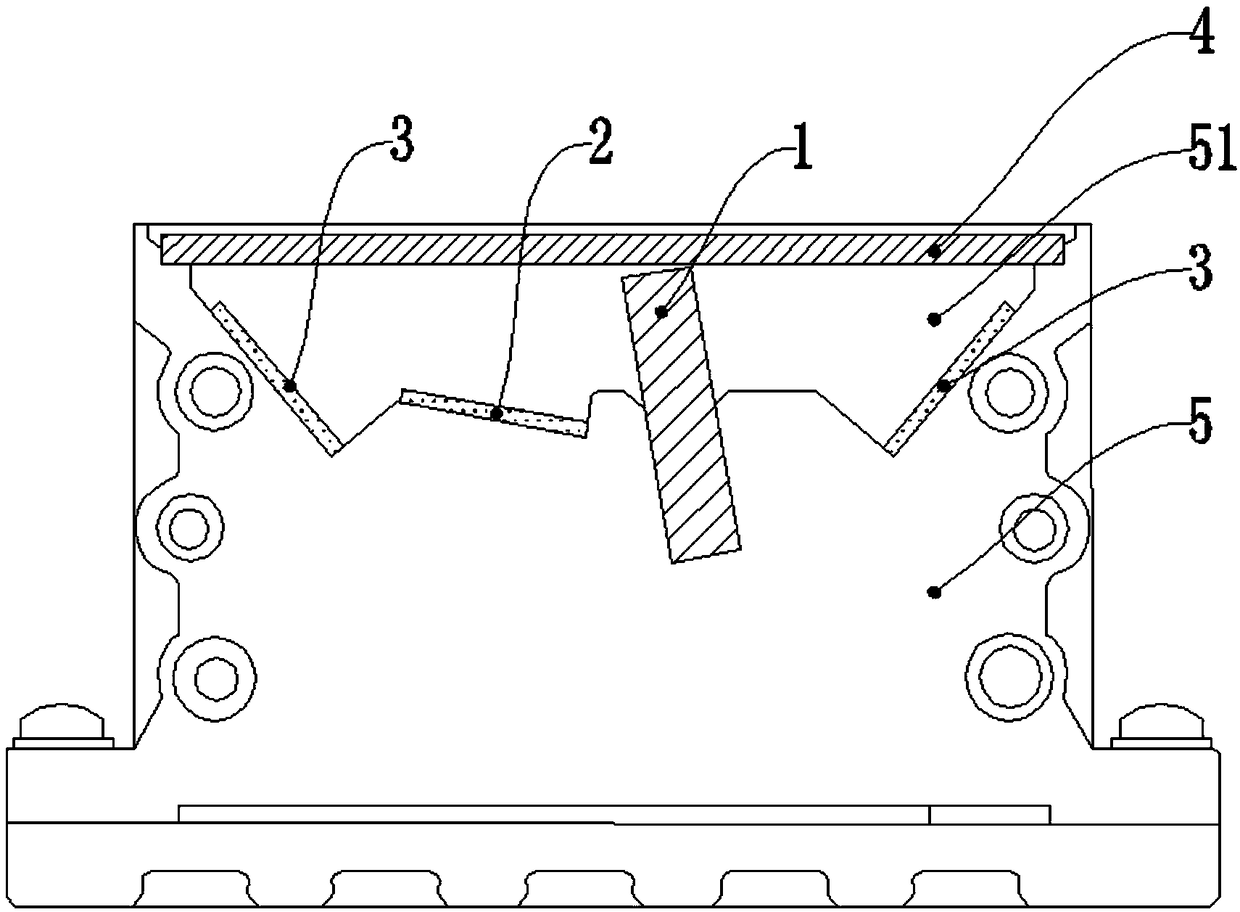

[0044] like Figure 3-6 As shown, a CIS camera and light source module for circuit boards, including a CIS line scan camera 1, a main light source 22 and an auxiliary light source 3, the main light source 22 and the auxiliary light source 3 are linear light sources;

[0045] The main light source 2 and the auxiliary light source 3 are located on the side of the CIS line scan camera 1, and provide light sources for the camera to shoot. There is at least the main light source 2 on one side of the optical axis of the CIS line scan camera 1, and the auxiliary light source 3 on the other side ;

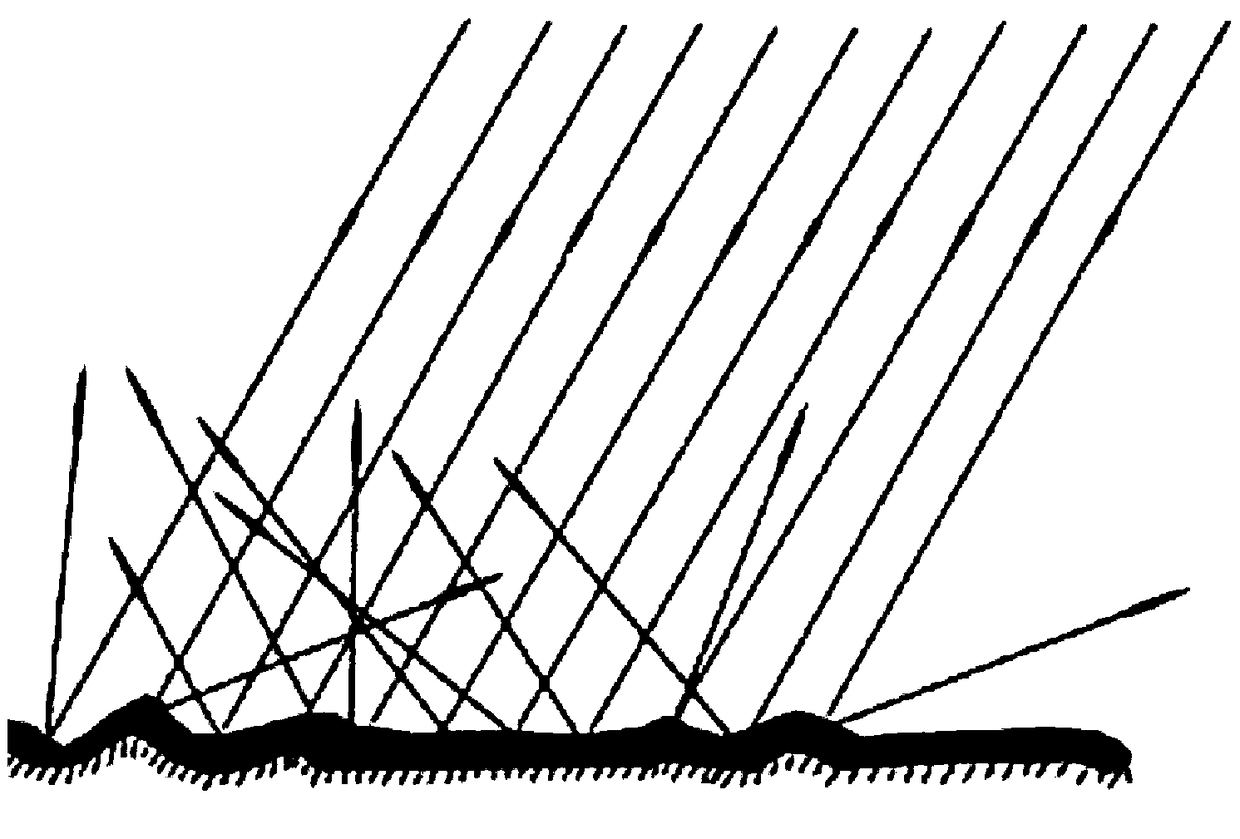

[0046]The light emitting direction of the main light source 2 and the auxiliary light source 3 has the photographed surface 01, the optical axis of the CIS line scan camera 1 is not perpendicular to the photographed surface 01, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com