A kind of contact lens for color blindness and color weakness correction and its manufacturing method

A technology for contact lenses and a manufacturing method, applied in the directions of glasses/goggles, optical components, instruments, etc., can solve the problems of being easily damaged, affecting the appearance, short service life, etc., to ensure structural stability, guarantee stability, guarantee The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

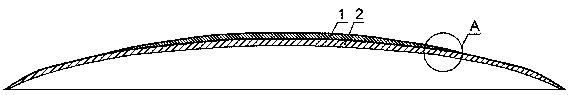

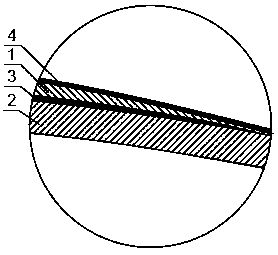

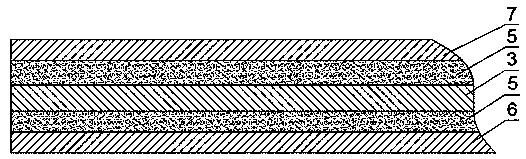

[0027] figure 1 and figure 2 Shown is a relevant structural diagram of a color-blindness and color-deficiency correction contact lens produced by the method for producing a color-blindness and color-deficiency correction contact lens according to this embodiment. The contact lens includes an outer layer 4, an intermediate layer 1, a color-blindness correction film 3 and an inner layer Layer 2, the manufacturing process of the contact lens comprises the following steps:

[0028] Step 1, making the middle layer 1 and the inner layer 2 by molding, the lower surface of the middle layer 1 matches the upper surface of the inner layer 2, the lower surface of the middle layer 1 is a concave arc su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com