Pixel structure, OLED (Organic Light-Emitting Diode) display panel comprising pixel structure, and vapor deposition mask

A technology of pixel structure and mask, which is applied in the fields of OLED display and evaporation mask, can solve the problems of narrowing of alignment space, disconnection of connecting bridge, color mixing, etc., and achieve the effect of reducing blurring and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

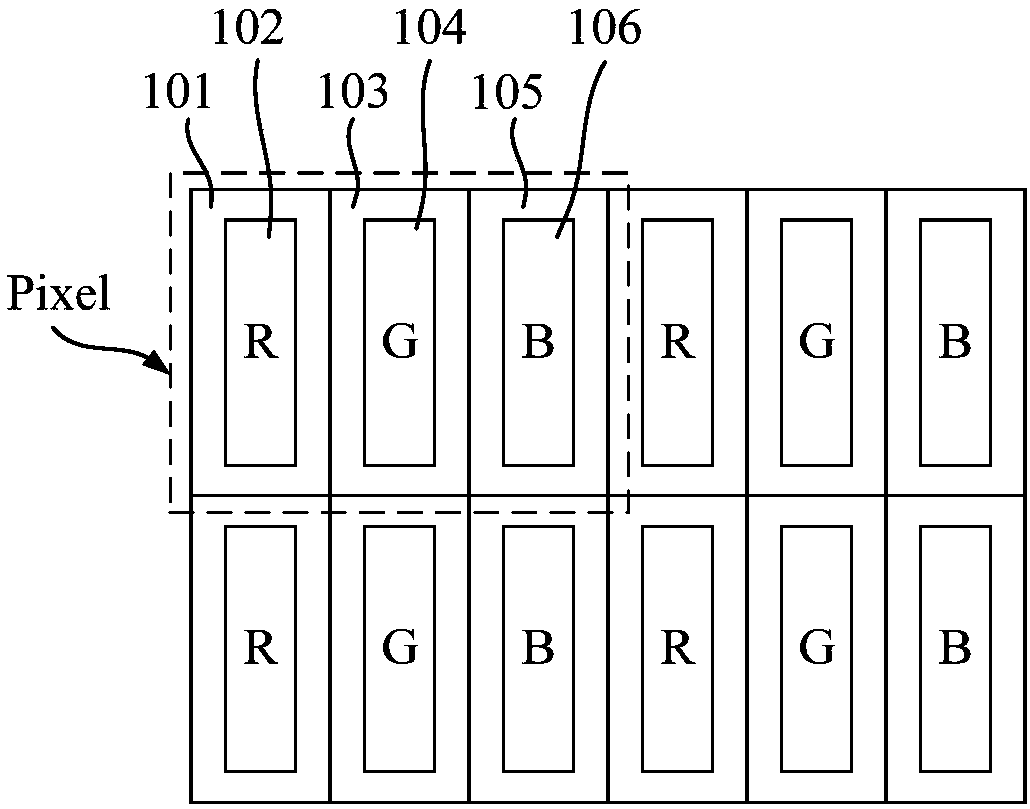

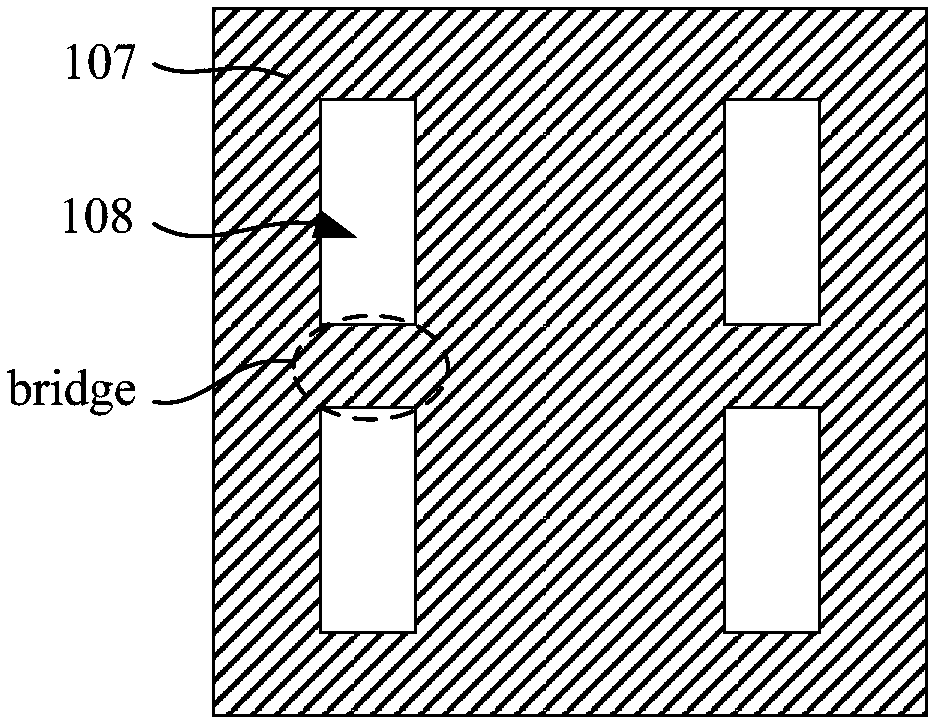

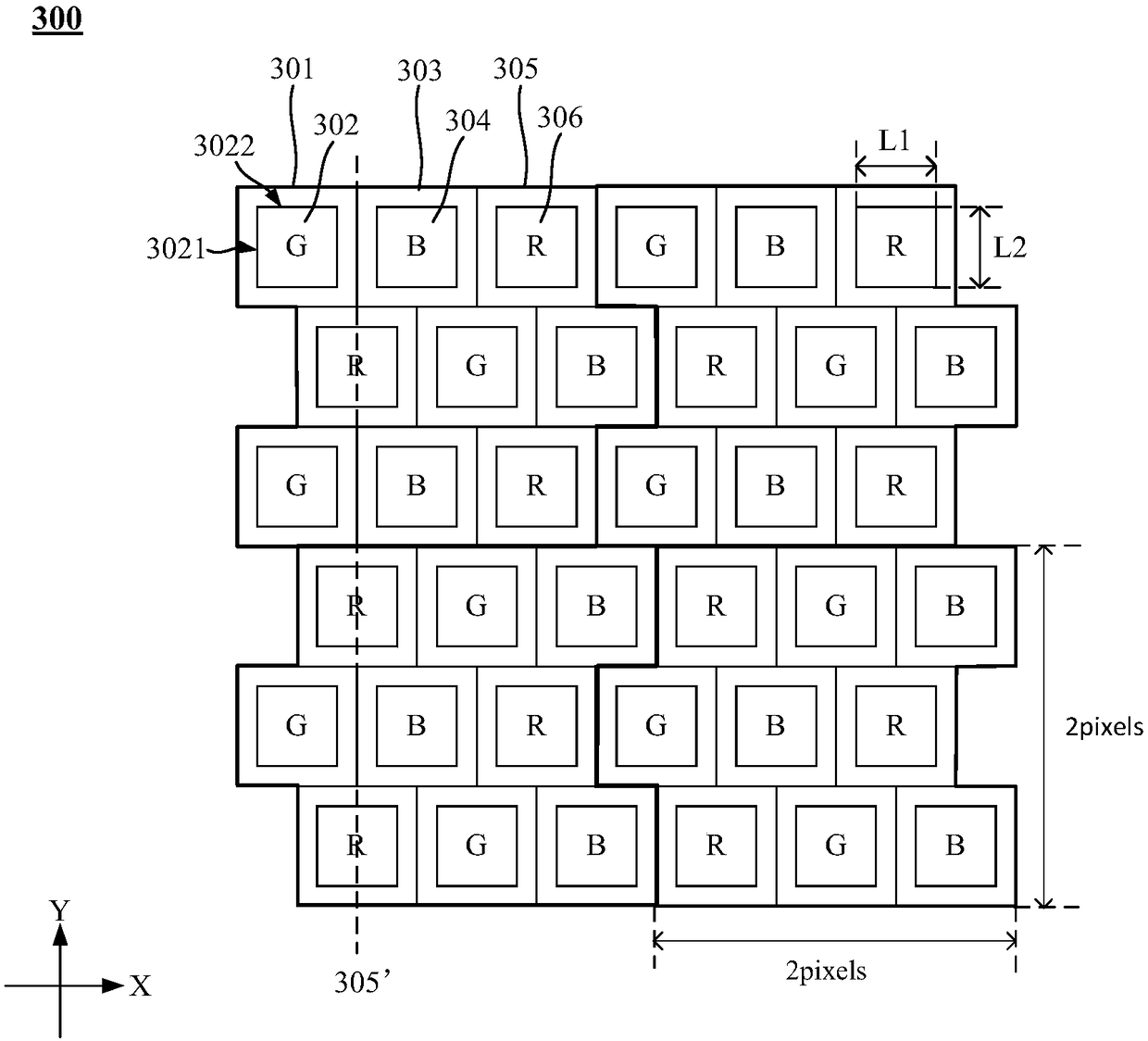

[0030] As mentioned in the background art, the technical focus of manufacturing a high-PPI OLED display lies in the fine and mechanically stable FMM and the arrangement of pixels. FMM is a key component in the vapor deposition pixel, and problems such as warpage and breakage should be minimized as much as possible to avoid defects that affect the quality of vapor deposition such as smearing and offset of the vapor deposition film layer. The arrangement of pixels and sub-pixels is the main reason for determining whether FMM is prone to warping and fracture. That is, the arrangement of pixels and sub-pixels largely determines the mechanical properties of the FMM, and the mechanical properties of the FMM largely determine the quality of evaporation. Such as figure 2 The FMM shown is to set the evaporation opening corresponding to the position of the sub-pixel of a certain color, because figure 1 The sub-pixels of the same color in the real RGB arrangement method are set up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com